PUMP COOLING REQUIREMENTS

10

Pumps are furnished with optional seal chamber jacket, jacketed

casing, jacketed mechanical seal gland, and bearing housing cool-

ing coil according to the pump service.

SEAL CHAMBER COOLING

Cooling is recommended under these conditions:

1) With a mechanical seal when the pumping temperature is

above 350°F. Individual plant specifications may require cool-

ing above 250°F.

Specific applications or liquids may require

cooling at lower temperatures.

2) With a mechanical seal when pumping liquids of 0.75 specific

gravity, or less, when the pumping temperature permits further

cooling.

3) With packing at temperatures above 250°F.

MECHANICAL SEAL GLAND COOLING

Mechanical seal gland cooling is generally applied under the same

conditions as those for seal chamber cooling. For pumping tempera-

tures only slightly above those requiring seal chamber cooling,

gland cooling may not be required on a specific application.

BEARING HOUSING COOLING

Cooling of the bearing housing is applied to cool the lubricating oil

and bearings. At pumping temperatures below 500°F. Such cooling

is rarely necessary. Excessive cooling of the bearing housing may

lead to early bearing failure from moisture condensation contamina-

tion of the oil.

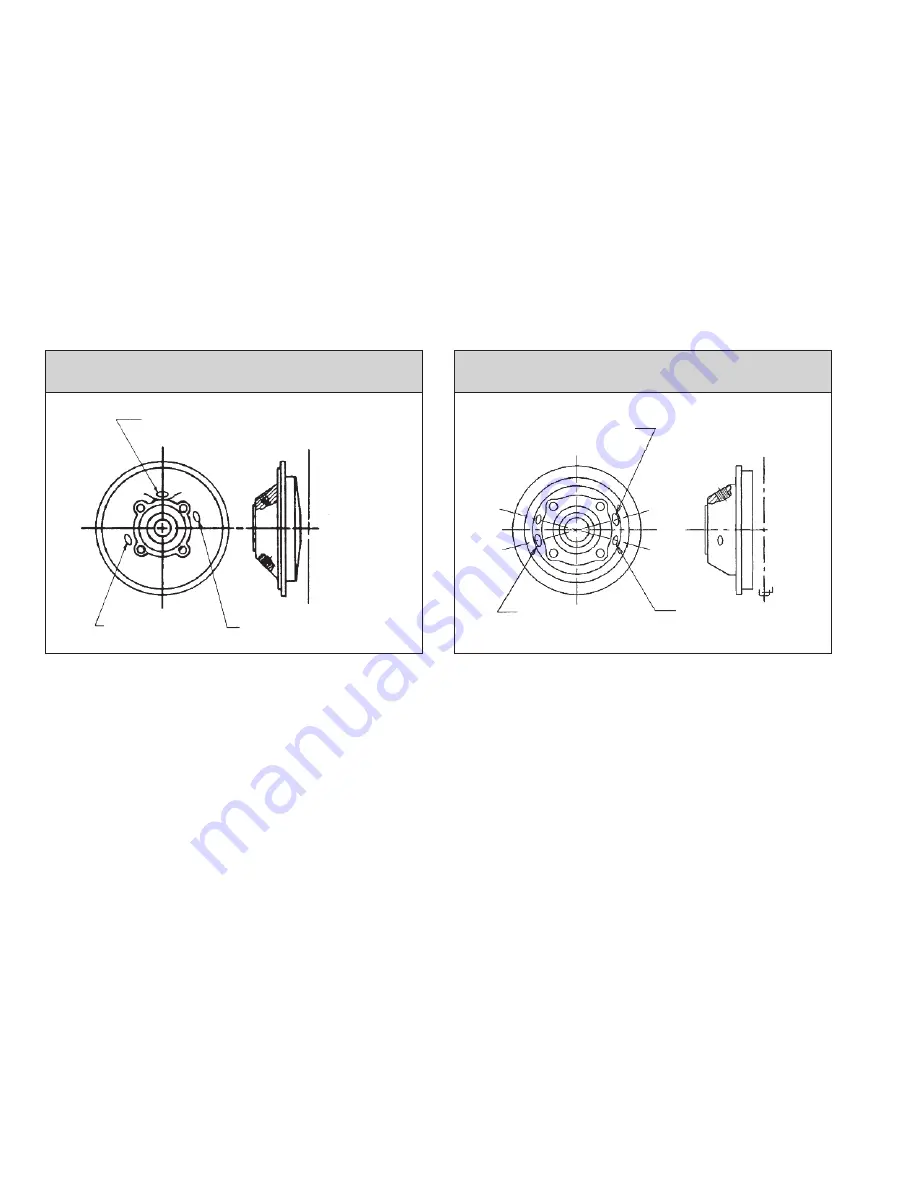

J

ACKETED

S

EAL

C

HAMBER

C

ONNECTIONS

P

H 2110 S

ERIES

P

UMPS

J

ACKETED

S

EAL

C

HAMBER

C

ONNECTIONS

P

H 2140/2170/3170 & 2180 S

ERIES

P

UMPS

INSTALLATION OF COOLING AND/OR SEAL CONNECTION PIPING TO THE PROPER CONNECTIONS IN MANDATORY. PUMP JACKET COOL-

ING WATER INSTALLED TO THE SEAL CONNECTIONS WILL RESULT IN INJECTION OF WATER INTO THE PUMPAGE WHICH MAY CAUSE SERI-

OUS CONTAMINATION OF THE PRODUCT AND HEAVY CORROSION. DEPENDING ON TEMPERATURE, IT MAY ALSO CAUSE A VIOLENT

STEAM EXPLOSION IN THE PUMP OR ASSOCIATED PIPING OR EQUIPMENT WITH EXTREME HAZARD TO PERSONNEL.

IMPORTANT WARNING

COOLING WATER PIPING

The cooling water piping depends on what cooling coil or jackets

are furnished and used. Jackets to be piped in series are Seal

Chamber Cooling, and Bearing Housing Cooling Coil, with the

cooling water to flow in that sequence. Not all of these jackets will

necessarily be used. All other jackets or cooling coil should be piped

in parallel with separate flow to each. The customer must provide

piping and a shut-off valve on each cooling inlet. The customer must

also provide the outlet piping from each jacket or cooling coil, fitted

with a pressure relief valve set at a maximum of 150 psig. and then

a flow control valve.

The relief valve is installed between the jacket and the flow control

valve to relieve any dangerous pressure that could develop in the

jacket. Pipe each outlet from the flow control valve to an open sight

drain or through a suitable flow indicating device into the plant cool-

ing water return system.

In no case should the outlet be piped into the municipal water

system.

Cooling jacket piping should be run to provide inlet water at the low-

est jacket connection and outlet from the highest connection.

COOLING WATER FLOW RATES

Seal chamber jacket cooling

water flow rates are related to pumping

temperature. A rate of 2 to 5 GPM is advisable, the higher rate at a

pumping temperature of 500°F.

Mechanical seal gland cooling

flow should be adjusted to about

1

/

2

GPM.

Bearing housing cooling coil

water flow rate should be adjusted to

1

/

2

GPM. This will maintain the bearing housing temperature in the

120°F to 200°F range. The pump may be operated without bearing

housing cooling if experience in the particular installation shows that

bearing housing temperatures do not rise above 200°F.

3/8” NPT

Seal Connection

1/2” NPT

Cooling Inlet,

Heating Outlet

1/2” NPT

Cooling Outlet,

Heating Intlet

WARNING: SEE

IMPORTANT

WARNING BELOW.

WARNING: SEE

IMPORTANT

WARNING BELOW.

Cooling Outlet,

Heating Inlet

Cooling Inlet,

Heating Outlet

Seal Connection

180° Apart

Discharge Flange