IOM-ALR-1

5

10. Re

move lower diaphragm plate (10).

11. Evenly loosen the three cage cap screws (18)

in single revolution increments.

NOTE:

Regu-

lator may con tain a lower piston spring (22);

the ITA should rise as the cage cap screws

(18) are evenly backed out. A down wards

holding force should be ap plied to the top of

the guide bearing (13) to pre vent the ITA from

pop ping up as the last threads of the cage cap

screws (18) are backed out.

12. Remove the ITA by pulling up on the valve

plug (20). Set ITA aside.

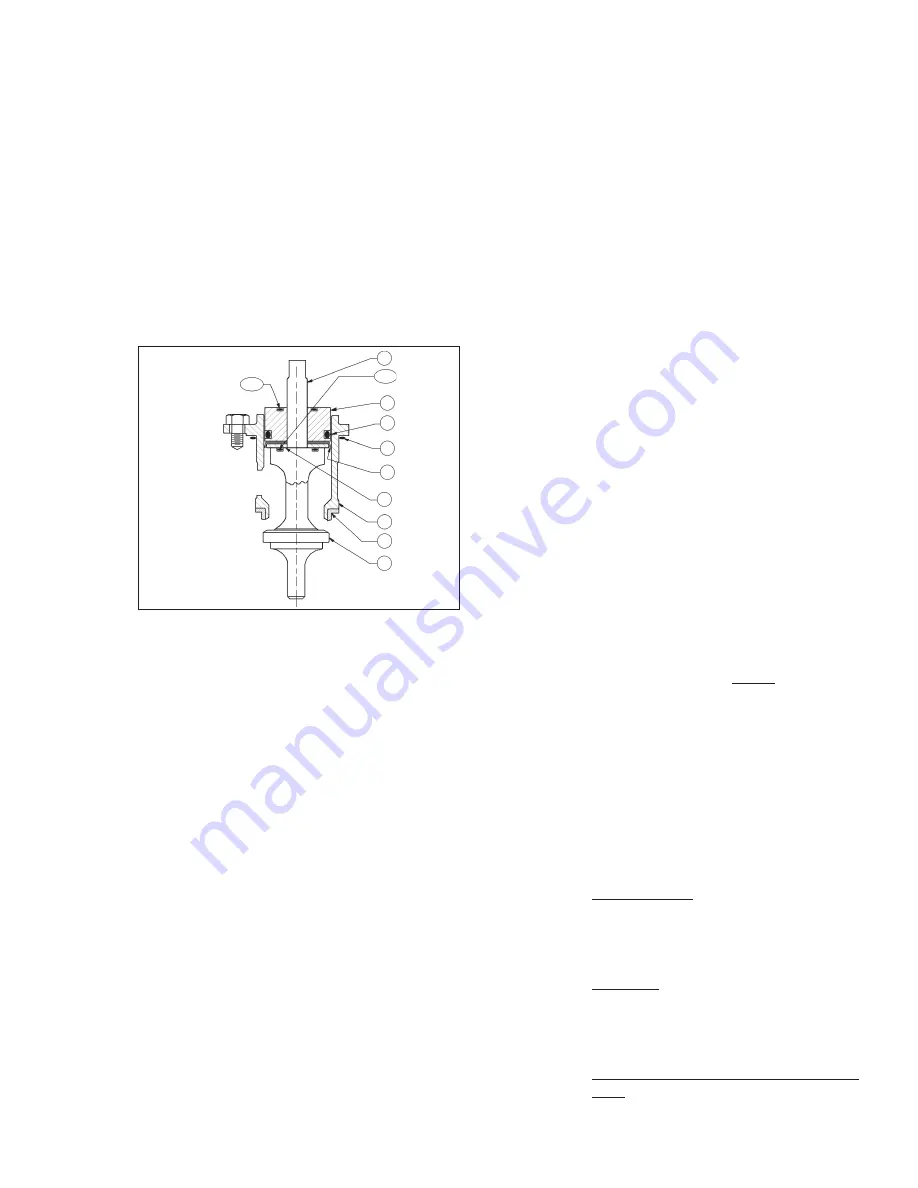

Figure 3:

Assembled ITA

13. Remove the lower piston spring (22), as ap-

pli ca ble, from within the body (23).

14. Remove o-ring cage seal (15).

15. If supplied, remove internal sensing drilled

plug (33) using 5/32" (4 mm) Allen wrench.

16. Remove body (23) from vise. Clean all re us able

metal parts according to owner's pro ce dures.

C. Disassembly of the ITA: (

See Figure 3)

1. Pull the valve plug (20) down wards and out

of the guide bear ing (13) and cage (19).

2. Remove the guide bearing (13) from the upper

end of the cage (19).

3. Remove o-ring middle stem seal (14.2) from

guide bearing (13).

4. Examine

the

com

po nents (27.1, 27.2, 27.3,

27.4) of the dy nam ic side seal (27) mechanism

to de ter mine if sig nif i cant leakage was oc cur-

20

21

19

17

16

15

27

13

14.3

20

14.2

ring. If the dy nam ic side seal (27) shows signs

of sig nif i cant leakage, de ter mine if op er at ing

con di tions are ex ceed ing pres sure, pres sure

drop, or tem per a ture limits.

Remove dynamic side seal (27) com po nents.

Special care should be taken when using

“tools” to remove the components to ensure

that no scratches are imparted to any portion

of the guide bearing (13) groove.

5. Remove wiper seal (16), if supplied, from within

cage (19) I.D.

6. Remove wiper washer (17.1) from within the

cage (19) I.D.

7. Remove o-ring lower stem seal (14.3) from

plug (20).

8. Remove seat ring (21); examine for signs of

leakage. If seat ring shows signs of significant

leakage, determine if op er at ing con di tions of

pressure, pressure drop, or temperature are

ex ceed ing limits.

9. Clean all reusable metal parts according to

owner's procedures.

D. Inspection of Parts:

1. After inspection remove from the work area

and dis card the old “soft goods” parts (i.e. o-

rings, di a phragms, seals, gaskets, etc.) after

in spec tion. These parts MUST be re placed

with fac to ry supplied new parts.

2. Inspect metal parts that will be reused. The

parts should be free of surface con tam i nants,

burrs, oxides, and scale. Rework and clean

parts as necessary. Surface con di tions that

affect the regulator performance are stated

below; replace parts that can not be re worked

or cleaned.

3. QC

Requirements:

a. Valve plug (20);

1. 16 rms finish on its seating surface

for tight shutoff.

2. No major defects on bottom guide

spin dle.

b. Cage

(19);

1. 16 rms finish on cylinder bore. No

“ledges” formed due to wear from

moving dynamic side seal (27) or

wiper seal (16).

c. Lower guide bushing (24) (non-re place-

able):