IOM-6987

3

A. General:

1. Maintenance procedures hereinafter are

based upon removal of the regulator unit from

the pipe line where installed.

2. Owner should refer to owner's procedures for

re mov al, handling, cleaning and disposal of

nonreusable parts, i.e. gaskets, etc.

3. Refer to Figure 2 for basic regulator parts.

B. Diaphragm Replacement:

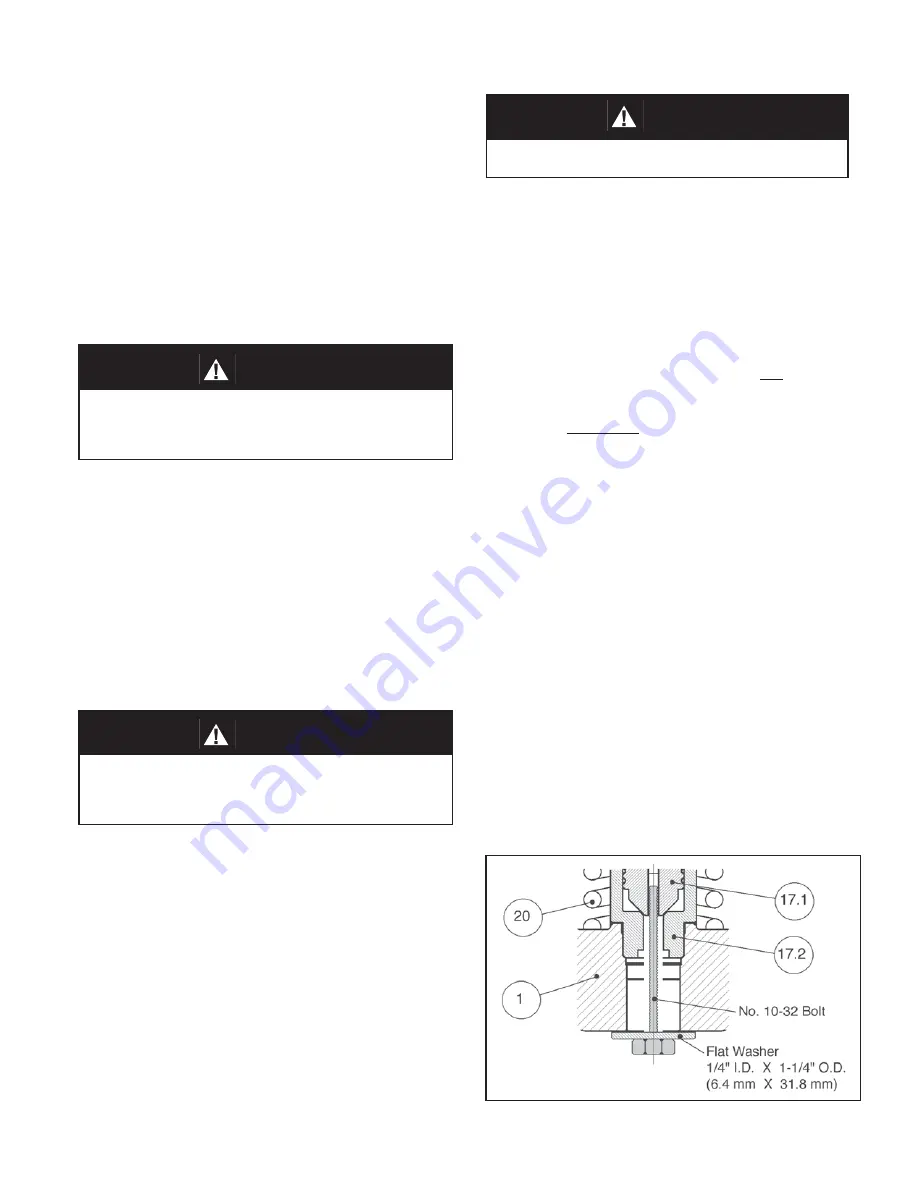

1. For regulators with NPT end connections

only, fabricate the special tool de scribed

in Figure 1. Rotate the No. 10-32 bolt CW

to col lapse the piston spring (20). This will

hold the renewal unit (17) in place during

dis as sem bly. For all other end con nec tion

options, proceed with Step 2.

2. Securely install the body (1) in a vise with the

spring chamber (2) directed upwards.

3. Loosen the adjusting screw lock nut (5) and

rotate the ad just ing screw (17) CCW until

re moved from the spring cham ber (2).

SECTION VI

VI. MAINTENANCE

4. Draw or em bed a match mark on the body (1)

and spring chamber (2) flanges.

5. If the special tool in Figure 1 is not being used,

the piston spring (20) is always under ten sion.

Therefore remove all flange bolts (13)

except two located on opposite sides. Turn

remaining two flange bolts (13) CCW using

even in cre ments. The piston spring (20) will

force the body (1) and spring cham ber (2) to

separate.

6. Remove spring chamber (2), spring buttons

(4), range spring (6), ball bearing (9),

pressure plate (8), diaphragms (10), and

diaphragm gasket (11).

7. Inspect pressure plate (8) for de for ma tion due

to over-pressurization. If de formed, re place.

8. Clean all parts to be reused according to

own er's procedures.

NOTE:

On reg u la tors

orig i nal ly sup plied as “spe cial cleaned”,

Op tion-55, main te nance must in clude a

level of clean li ness equal to Cash co’s

clean ing stan dard #S-1134. On reg u la tors

orig i nal ly sup plied as “spe cial cleaned”,

Op tion-56, main te nance must in clude a level

of clean li ness equal to Cash co’s clean ing

stan dard #S-1542. Con tact fac to ry for details.

SECTION V

2. If the reg u la tor and system are both to be

shut down, slowly close the inlet (upstream) block

valve. Close the outlet (downstream) valve only if

regu la tor re moval is required.

V. SHUTDOWN

1. On systems with a bypass valve, and where

sys tem pres sure is to be maintained as the

regu la tor is shut down, slowly open the bypass

valve while closing the inlet (upstream) block

valve. Fully close the inlet (up stream) block valve.

(When on bypass, the system pressure must be

con stant ly observed and manually reg u lat ed.

Close the outlet (down stream) block valve.

Figure 1:

Special tool for collapsing piston spring (20).

CAUTION

Do not walk away and leave a bypassed reg u la tor

un at tend ed!

WARNING

SYSTEM UNDER PRESSURE. Prior to performing any

main te nance, isolate the regulator from the system

and relieve all pressure. Failure to do so could result in

personal injury.

WARNING

SPRING UNDER COMPRESSION. Prior to removing flange

bolts, relieve spring compression by backing out the ad-

justing screw. Failure to do so may result in flying parts

that could cause personal injury.