T-318

3

−

3

COOL

HEAT DEFROST IN RANGE ALARM

SUPPLY RETURN

SETPOINT/Code

AIR TEMPERATURE/Data

Figure 3-3 Display Module

3.1.3 Controller

CAUTION

Do not remove wire harnesses from con-

troller unless you are grounded to the unit

frame with a static safe wrist strap.

CAUTION

Unplug all controller wire harness connec-

tors before performing arc welding on any

part of the container.

CAUTION

Do not attempt to use an ML2i PC card in an

ML3 equipped unit. The PC cards are physi-

cally different and will result in damage to

the controller.

NOTE

Do not attempt to service the controller. Break-

ing the seal will void the warranty.

The Micro-Link 3 controller is a single module

microprocessor as shown in Figure 3-4. It is fitted with

test points, harness connectors and a software card

programming port.

3.2 CONTROLLER SOFTWARE

The controller software is a custom designed program

that is subdivided into the configuration software and the

operational software. The controller software performs

the following functions:

a. Control supply or return air temperature to required

limits, provide modulated refrigeration control, elec-

tric heat control, and defrost. Defrost is performed to

clear buildup of frost and ice from the coil to ensure

continuous conditioned air delivery to the load.

b. Provide default independent readouts of set point and

supply or return air temperatures.

c. Provide ability to read, and if applicable, modify the

configuration software variables, operating software

function codes, and alarm code indications.

d. Provide a Pre-trip step-by-step checkout of

refrigeration unit performance, including proper

component operation, electronic and refrigeration

control operation, heater operation, probe calibration,

pressure limiting, and current limiting settings.

e. Provide battery-powered ability to access or change

selected codes and set points without AC power

connected.

f. Provide the ability to reprogram the software through

the use of a memory card.

3.2.1 Configuration Software (CnF Variables)

The configuration software is a variable listing of the

components available for use by the operational

software. This software is factory-installed in

accordance with the equipment fitted and options listed

on the original purchase order. Changes to the

configuration software are required only when a new

controller has been installed or a physical change has

been made to the unit such as the addition or removal of

an option. A configuration variable list is provided in

Table 3-4. Change to the factory

−

installed configuration

software is achieved via a configuration card or by

communications.

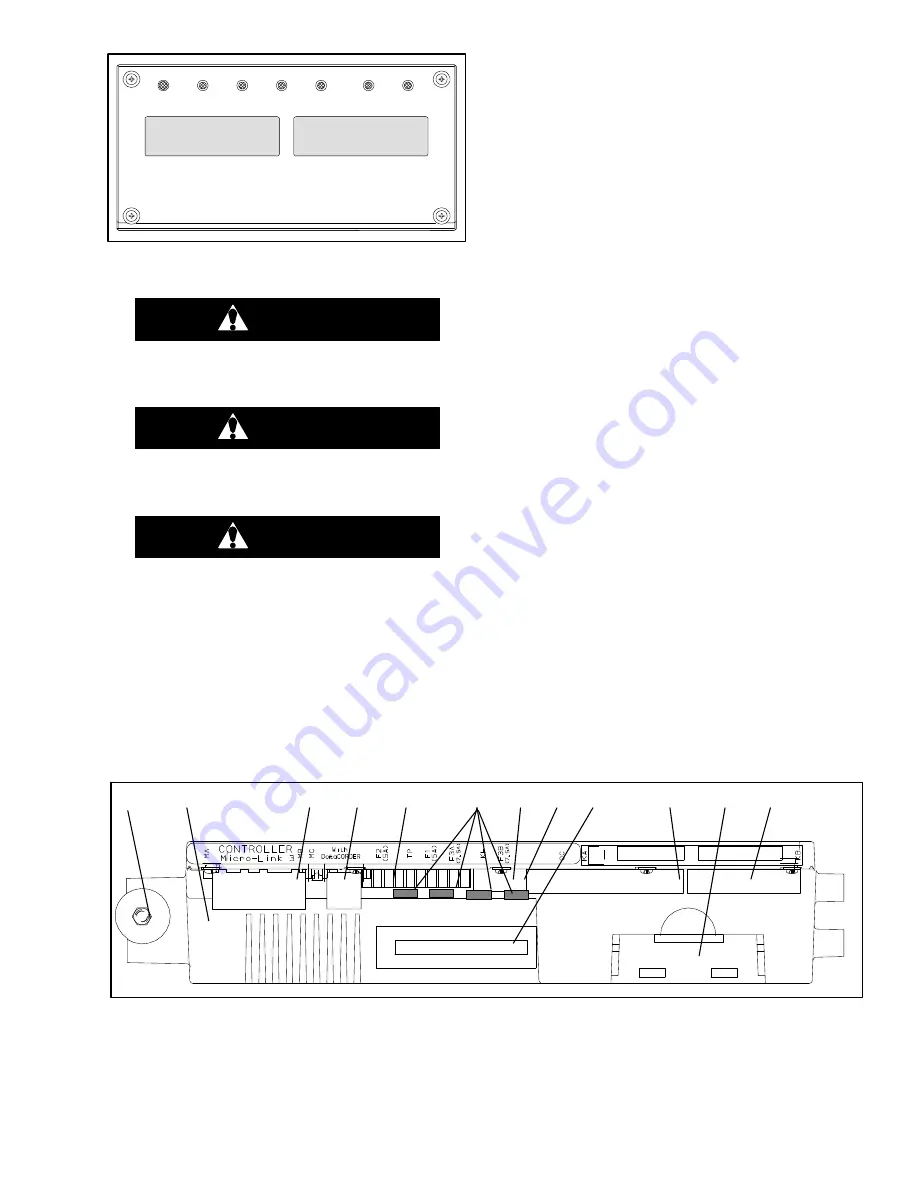

1. Mounting Screw

2. Micro-Link 3 Controller

3. Connectors

4. Test Points

5. Fuses

6. Control Circuit Power Connection

located on back of controller)

7. Software Programming Port

8. Battery Pack

Figure 3-4 Control Module

Содержание 69NT40-541-300

Страница 2: ......

Страница 4: ......

Страница 20: ......

Страница 32: ......

Страница 128: ......

Страница 131: ...7 3 T 318 Based on Drawing 62 66058 Figure 7 2 SCHEMATIC DIAGRAM Units with 3 Phase Evaporator Motors...

Страница 133: ...7 5 T 318 6 Heater FCCH FCCH Figure 7 4 SCHEMATIC DIAGRAM Units with Normal Evaporator Fan Capability...

Страница 134: ...7 6 T 318 FCCH FCCH Figure 7 5 SCHEMATIC DIAGRAM Units with Single Evaporator Fan Capability...

Страница 136: ...7 8 T 318 To ST10 To TRX2 To QC1 To QC1 To QC1 To MC6 CONTROLLER Figure 7 7 SCHEMATIC DIAGRAM Emergency Bypass...

Страница 138: ...7 10 T 318 Based on Drawing 62 66058 Figure 7 9 UNIT WIRING DIAGRAM Units with 3 Phase Evaporator Motors Sheet 1 of 2...

Страница 139: ...7 11 T 318 Based on Drawing 62 66058 Figure 7 10 UNIT WIRING DIAGRAM Units with 3 Phase Evaporator Motors Sheet 2 of 2...

Страница 144: ......

Страница 150: ......

Страница 151: ......