46

12 - FACTORY OPTIONS AND ACCESSORIES

■

Air/gas premixing operation:

The PCH heater is

fi

tted with a burner that completely premixes

air and gas. The air/gas mixing occurs inside the impeller on

the motor-fan.

The air taken into the impeller through the venturi tube,

calibrated, creates a vacuum. The vacuum in the venturi is

rebalanced by the gas valve, which is pneumatically controlled.

The air pressure - gas pressure ratio is 1:1. This ratio can be

corrected by turning the o

ff

set adjustment screw (on the gas

valve). The heater is supplied with the o

ff

set regulated and the

screw sealed.

A second adjustment can be done with the screw on the

venturi, which regulates the value of maximum gas capacity

and determines the amount of carbon dioxide (CO

2

) in the

fl

ue

gases.

This adjustment is also made at the factory. The screw is not

sealed to permit conversion to another type of gas, if desired.

The modulation PCB, mounted on the heater, manages the

motor rotation (in c.c.) depending on the heating capacity

required by the environment. Varying the rotation speed of the

motor changes the air

fl

ow capacity and therefore also the gas

fl

ow capacity. Minimum and maximum rotation values of the

fan are programmed into the PCB and cannot be modi

fi

ed by

the user or installer.

Control of the gas burner

Important:

All the connections to be established by the

client are featured on the wiring diagram included with

the unit.

■

Unit electronic control:

“50FC” control has a proportional output 0/10V (Y2) where

a natural gas or propane gas proportional actuator can be

connected.

The burner connection is managed by the control, in HEATING

mode, through an ON/OFF signal of the digital output NO5

- It is possible to select three operating modes for the burner:

- Operation of the burner as one or two electrical heater stages

(both option not compatible).

- Operation instead of the compressors.

- Operation instead of the compressors if the outdoor

temperature is lower than the value set (5ºC by default).

When the return temperature drops below the value set for the

burner connection the burner will start to operate. The control

of the power is carried out in accordance with the temperatures

of the supply air and return air. The control compares both

temperatures. If the supply temperature is excessively high,

the control limits the power supplied by the burner despite the

demand. This comparison avoids the strati

fi

cation of the hot

air masses and keeps the supply temperature below the safety

value (55ºC by default), which stops the burner.

Moreover, the control compares the supply temperature and the

ambient temperature to improve the feeling of thermal comfort.

The gas burner integrates its own control. “50FC” control only

receives a safety signal from the burner in the event of failure

(digital input DI5). This signal only indicates the failure.

■

Burner control:

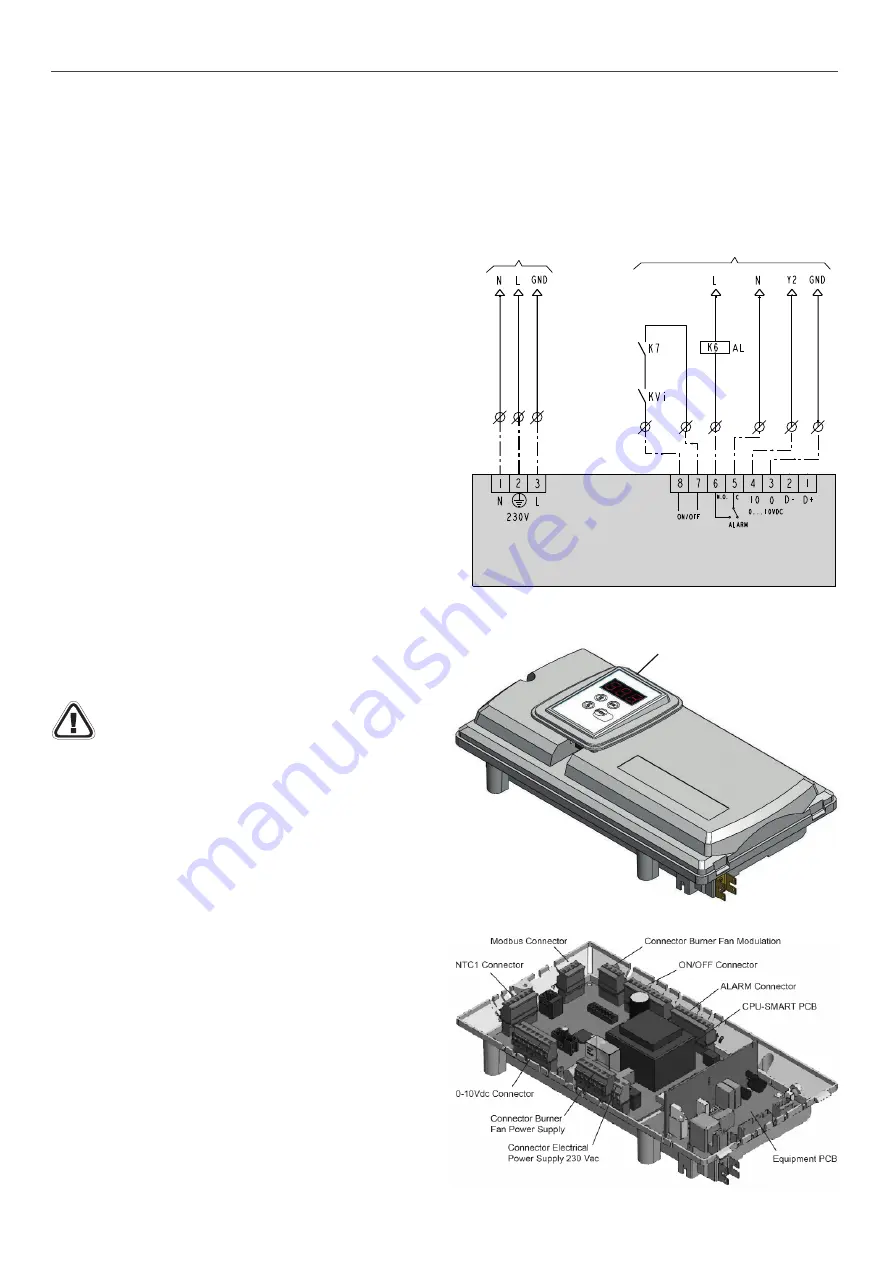

The gas burner integrates its own CPU-SMART PCB board

that manages the operation and the safety devices.

The cables “W48-QUE” and “W49-QUE” with the wires

required for the connection of the CPU-SMART PCB board

with the 50FF/FC unit must be connected to the connection

box “BOX8-QUE” that is located inside of the 50FF/FC unit

(please consult the paragraph “Electrical connection of the

burner”.

CPU PCB LCD

Detail of CPU-SMART PCB board

CPU-SMART PCB

burner control

Supply fan

Switch on signal

J13 - NO5

(”50FC” control)

Connector M1

Connector M2

230 - I - 50Hz

47

48

49

40

41

42

43

44

45

W48-QUE

W49-QUE

■

Fxx faults:

The modulation PCB can distinguish between 30 di

ff

erent types

of faults. This ensures accurate diagnostics. Also, codes and

possible causes of faults are listed in this manual.

For more serious faults that require a manual reset, use the

LCD display to reset the CPU PCB on the machine by pressing

the arrows at the same time.

Содержание 50FC Series

Страница 63: ......