Maintenance and Cleaning

Dynacode IP Series

90

Operating Manual

08.16

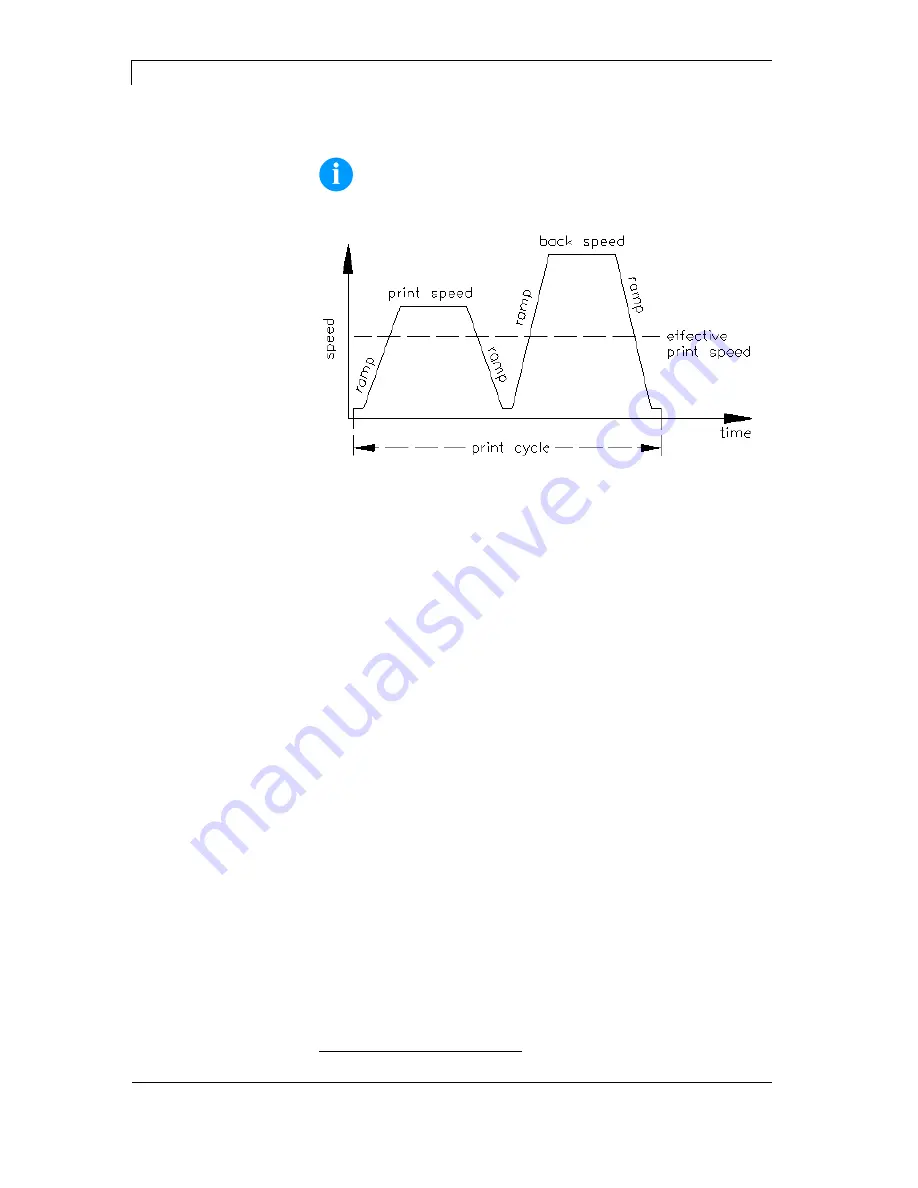

14.7 Cycle optimisation*

NOTICE!

The cycle is a finished print cycle per a unit of time.

Figure 35

In case of 'time critical' applications you have the possibility with a

good selection of different device parameters to increase the effective

print speed and it this way the clock cycle.

Generally increase the print speed.

Generally increase the back speed.

Increase acceleration and brake ramp.

Change zero point of machine.

Avoid vertical installation position of print mechanics. Install the

machine in horizontal position.

Control the short distance between printhead and print surface.

Switch off foil saving automatic.

Optimise the layout to a short print way, i.e. less blanks, no

borders at the top res. bottom, rotate the layout.

*

intermittent mode