13.

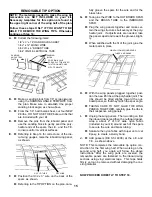

Next, cut 45º slots on each side of each hole to

accommodate the hinge webs.

NOTE:

The CGM hinge slotting kit (Item # 600) is handy

for this process.

14.

Move the elevator close to the edge of the table

and support the thin edge with wing rib scrap, as

shown.

Carefully cut hinge slots, as, at the proper loca-

tions.

15.

Repeat the slotting method for the fin and rud-

der.

16.

Referring to the above diagrams, assemble the

beveling tool. First glue the narrow strip to the

handle, taking care to keep it square. Then glue

the wide strip to the handle and the narrow strip.

When the glue has dried, cut a strip of 100-200

grit sandpaper to size and tack-cement the

sandpaper to the tool, as shown.

17.

Tape the T.E. of the elevator to the work surface.

Using the beveling tool, sand the L.E. to the

centerline. Then turn the parts over and bevel

the other side.

Repeat this process for the rudder. When fin-

ished the pieces should look like the drawing

below.

THIS COMPLETES THE TAIL CONSTRUCTION.

PUT THE PIECES ASIDE UNTIL THEY ARE NEED-

ED LATER.

B E V E L I N G -

COMPLETED

11

SCRAP PLY

WING SHIM

END VIEW THOUGH ELEVATOR