1.

Insert the soft rubber grommets into the mount-

ing holes of your servos.

2.

Measure from the bottom of your servo to the

underside of a grommet. Add about 1/8” to this

measurement to get the total distance between

the wing platform and the servo rail.

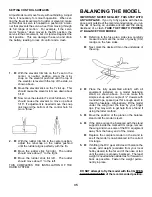

Referring to the plan, glue the rear rail against

Former “C”, at the predetermined height.

Place a servo on the rear rail and determine

the location of the front rail. Be sure to allow

enough clearance to allow easy insertion and

removal of both servos.

Glue the front servo rail in place.

3.

Place both the rudder servo and the elevator

servo in position on the servo rails. The eleva-

tor servo goes on the right (as viewed from the

pilot’s seat) and the rudder servo goes on the

left. There should be approximately 1/4”

between them.

Mark through the grommets for the location of

the servo mounting screws. Remove the ser-

vos.

Using a 1/16” drill bit, drill holes through the

rails for the screws.

4.

Referring to the plan, and using #2 x 3/8” sheet

metal screws, install the rudder servo on the

left and the elevator servo on the right.

Untape the pushrod wires and attach each of

them to the corresponding servo, as shown.

2.

Remove the servo wheel and install the CGM

pushrod connector, as shown. This device lets

you easily adjust the motor pushrod movement.

Remount the servo wheel with the pushrod con-

nector in the approximate position shown on the

fuse top view on the plan.

3.

From 1/16” scrap wire, cut a 2-1/8” length.

Make a 1/4” bend at the end. Roughen the

unbent end with sandpaper.

Slip the Snap-R-Keeper on the wire with the

clips toward the bend.

MOTOR SERVO INSTALLATION (3-CHANNEL)

1.

Referring to the plan for proper location, insert

the motor servo onto the fuse side with servo

mounting tape.

ELEVATOR AND RUDDER SERVO INSTALLATION

4.

Position a CGM snap nut about 1” onto the

straight end of the wire.

Insert the wire through the pushrod connector

and add a second snap nut. (Trim the snap

nuts if they rub against the servo wheel.)

5.

Attach the bent end of the wire to the motor

switch bracket and secure by sliding the Snap

R Keeper clips over the bend.

Move the pushrod back and forth to simulate

servo action. Feel the OFF and ON switch lim-

its. Later, when setting controls, be sure to

adjust the snap nuts within the range of switch

movement.

INVERTED FUSE

33