7

○

Refrigerant jet noise

Fault: a continuous noise like a water spray from the capillary.

Causation: the end of the capillary is in the wrong position, or there are rough edges on the end of the

capillary.

Solution :

1>. Heat the soldered joint of the capillary

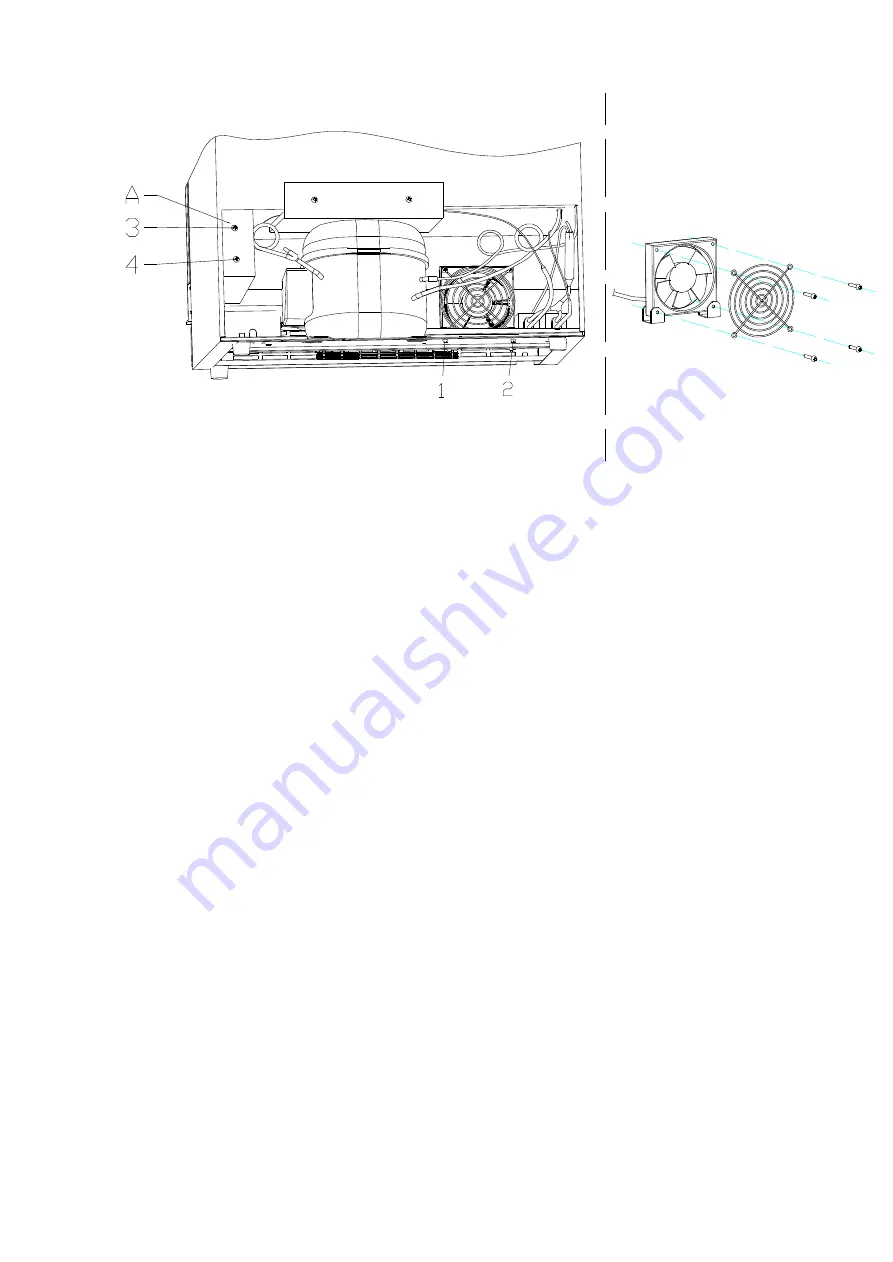

(Fig.3 showing A point)

, then remove the capillary from the

evaporator and smooth the end with an eraser. (Caution: do not allow any particles into capillary unit).

2>. Replace the capillary into the evaporator, then solder it back into the correct position (not exceeding

15mm in the evaporator) and pack the joint with anti vibration compound.

3>. Vacuumize and recharge with refrigerant. See

(

→

2)

○

Capillary vibration noise

Fault: high frequency impact noise in capillary Zone. Caused by either

Causation:

1>. The capillary being insert too deep into the evaporator, so when the refrigerant is Jetting, the end of

vibrating capillary will hit the inside of the evaporator.

2>. Vibration from the capillary touching the inside of the cabinet or air duct board, then when refrigerant

is jetting.

Solution:

1>. If the capillary is inserted too deep, heat it with the solder, solder it again(Please noted, the deep inserted

is not bigger than 15mm), and vacuumize it and add the refrigerant.

(

→

2)

2>. If the capillary touch the inner cabinet or the air duct panel, adjust the position of the capillary and add

the incabloc plastic.

(Fig.3)

○

Oil jam noise

Fault: intermittent and deep jet noise coming from inside of the capillary.

Causation: Compressor oil flowing into the cooling system pipe work probably due to the unit leaning during

Fig. 6

Fig. 6.1

Содержание WI6225

Страница 1: ...WI6225 Caple 60cm 2 Door Wine Cabinet Technical information...

Страница 2: ......

Страница 3: ......

Страница 6: ......