*1: When paper is not soiled, cleaning is complete. Change paper each time cleaning is performed.

*2: Locations to clean in servicing when soiling on paper in automatic duplex printing persists:

* Occurrence level:

A: The symptom is likely to occur frequently. (Caution required)

B: The symptom may occur under certain conditions, but likeliness is assumed very low in practical usage.

C: The symptom is unlikely to be recognized by the user, and no practical issues are assumed.

To the top

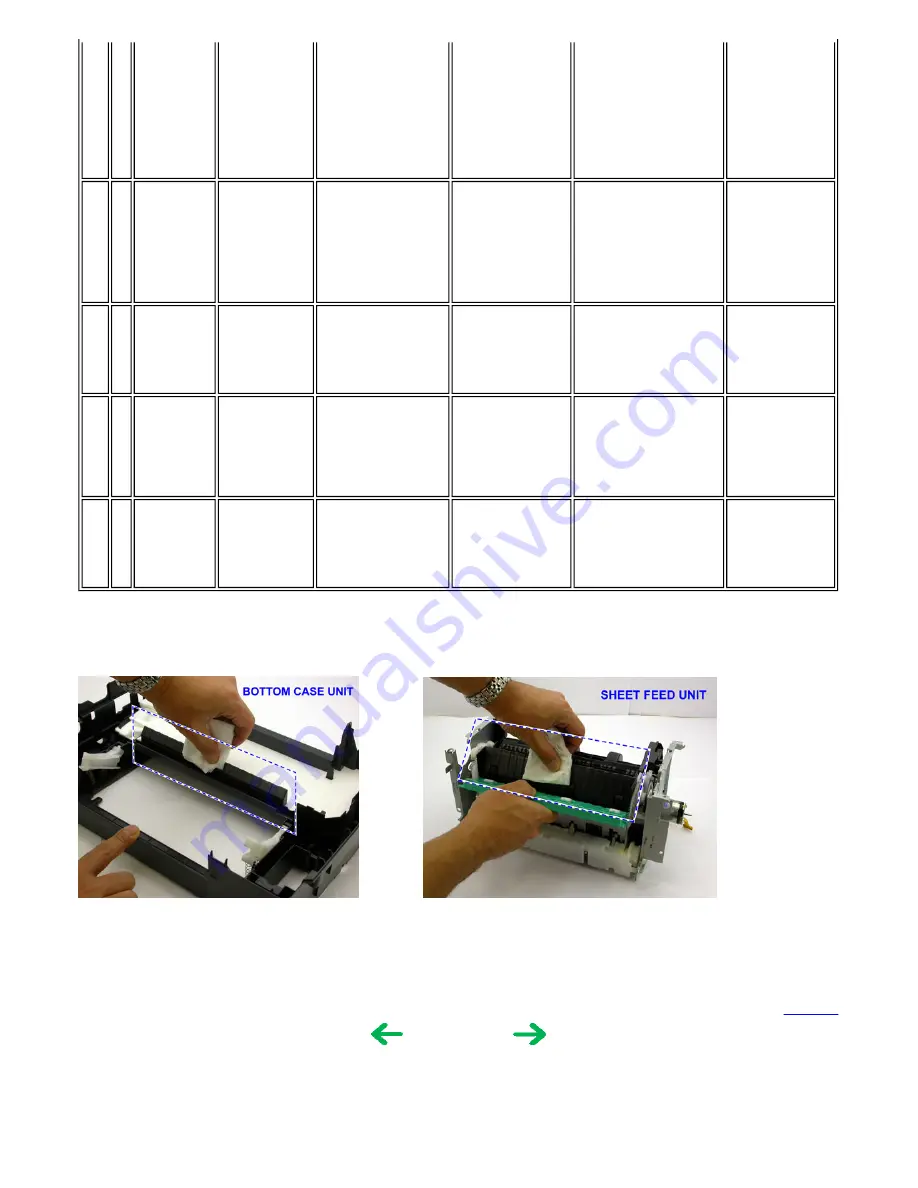

cotton swab.

If the phenomenon persists after

conducting 1 and 2, servicing is

required.

Service:

Wipe any soiling or dirt off

from the sheet feed unit and the

bottom case unit ribs

*2

.

8

C

Print results

Scratches on paper

- PP-101D, PP-101, PR-

101, SG-101, etc.

- Paper feeding from the

cassette

- Multiple number of sheets

loaded

- Paper is scratched.

- Marks appear on

printed paper.

- Change the paper feeding

method from the cassette to

the sheet feeder.

- If automatic duplex printing is

performed, cancel it, and, by

setting only a single sheet of

paper in the auto sheet feeder,

manually print each side of

paper.

Scratches on the PF

return lever due to

paper feeding from the

cassette, and duplex

printing path.

9

B

Print results

Soiling on the print

surface of a page

- PSHR, KM-101

- PR-101 (L, 4" x 6")

Paper is curled

- Widen space between paper

and paper

- Flatten paper

Paper is soiled.

10

-

Paper feeding

(specifications)

Credit/name card -

sized paper can not

be ejected.

- KM-101, MM-101

- GP-401 Credit Card

Paper is set sideways in

the sheet feeder.

Set paper vertically in the sheet

feeder.

'This paper size can be fed by

setting paper vertically in the

sheet feeder. Feeding through

the cassette is not possible.)

Paper is not ejected.

11

-

Print result

(specifications)

To change color

hue at Direct Print,

as color hue is red-

tinged.

At Direct Print

Color hue is different

from the desired colors.

Perform color adjustment on the

operation panel.

Color hue is not

normal.

<Part 2: 5. FAQ>

2 - 20

Содержание PIXMA iP6000D

Страница 7: ...Part 1 MAINTENANCE ...

Страница 15: ... II DCC holder unit wiring III Paper feed motor side wiring To the top Part 1 3 REPAIR 3 2 1 8 ...

Страница 17: ... 3 Grease application 1 10 ...

Страница 27: ...Part 2 TECHNICAL REFERENCE ...