Note: 1 drop = 9 to 18 mg

To the top

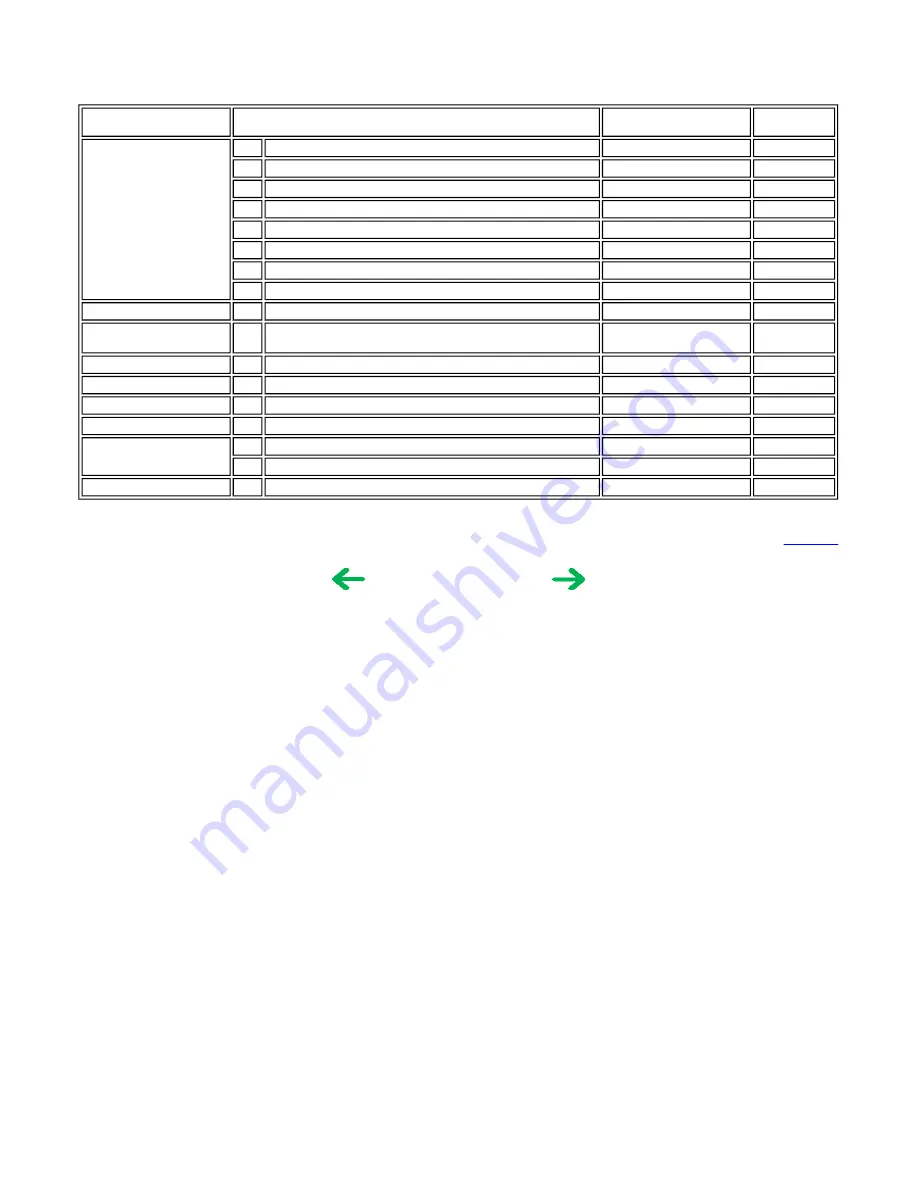

Part name

Where to apply grease / oil

Grease / oil name

Grease / oil

amount

Chassis

1

Entire contact surface of the carriage slider rail

FLOIL KG107A

3 drops

2

Cam contact portion

FLOIL KG107A

1 drop

3

Carriage shaft sliding portion

FLOIL KG107A

1 drop

4

Carriage shaft cam L sliding portion

MOLYKOTE HP300

2 drops

5

Carriage shaft sliding portion

FLOIL KG107A

1 drop

6

Carriage shaft sliding portion on the left side of the chassis

FLOIL KG107A

1 drop

7

Carriage shaft cam L sliding portion on the left side of the chassis

FLOIL KG107A

2 drops

8

Carriage shaft sliding portion on the right side of the chassis

FLOIL KG107A

1 drop

Carriage shaft

9

Entire surface of the carriage shaft where the carriage unit slides

FLOIL KG107A

200 to 400mg

Carriage shaft spring L

10

Carriage shaft sliding portion (over the area more than 2/3 from the top

end of the spring)

FLOIL KG107A

1 drop

Lift gear 2 shaft

11

Outer surface of the stepped portion where the spring slides

MOLYKOTE HP300

1 drop

Lift gear 2

12

Outer surface of the spring sliding bushing

MOLYKOTE HP300

1 drop

Chassis

13

Carriage shaft cam R sliding portion

MOLYKOTE HP300

1 drop

Transmission gear

14

Inner surface

MOLYKOTE HP300

1 drop

Lift shaft

15

Spring sliding portion (4 locations)

FLOIL KG107A

1 drop

16

Pressure roller ass'y contact portion (4 locations)

FLOIL KG107A

1 drop

Feed roller ass'y

17

Spring contact bushing

FLOIL KG107A

Half drop

<Part 1: 3. REPAIR, 3-3 (1) to (3)>

1 - 11

Содержание PIXMA iP6000D

Страница 7: ...Part 1 MAINTENANCE ...

Страница 15: ... II DCC holder unit wiring III Paper feed motor side wiring To the top Part 1 3 REPAIR 3 2 1 8 ...

Страница 17: ... 3 Grease application 1 10 ...

Страница 27: ...Part 2 TECHNICAL REFERENCE ...