18

GAS CONTROL

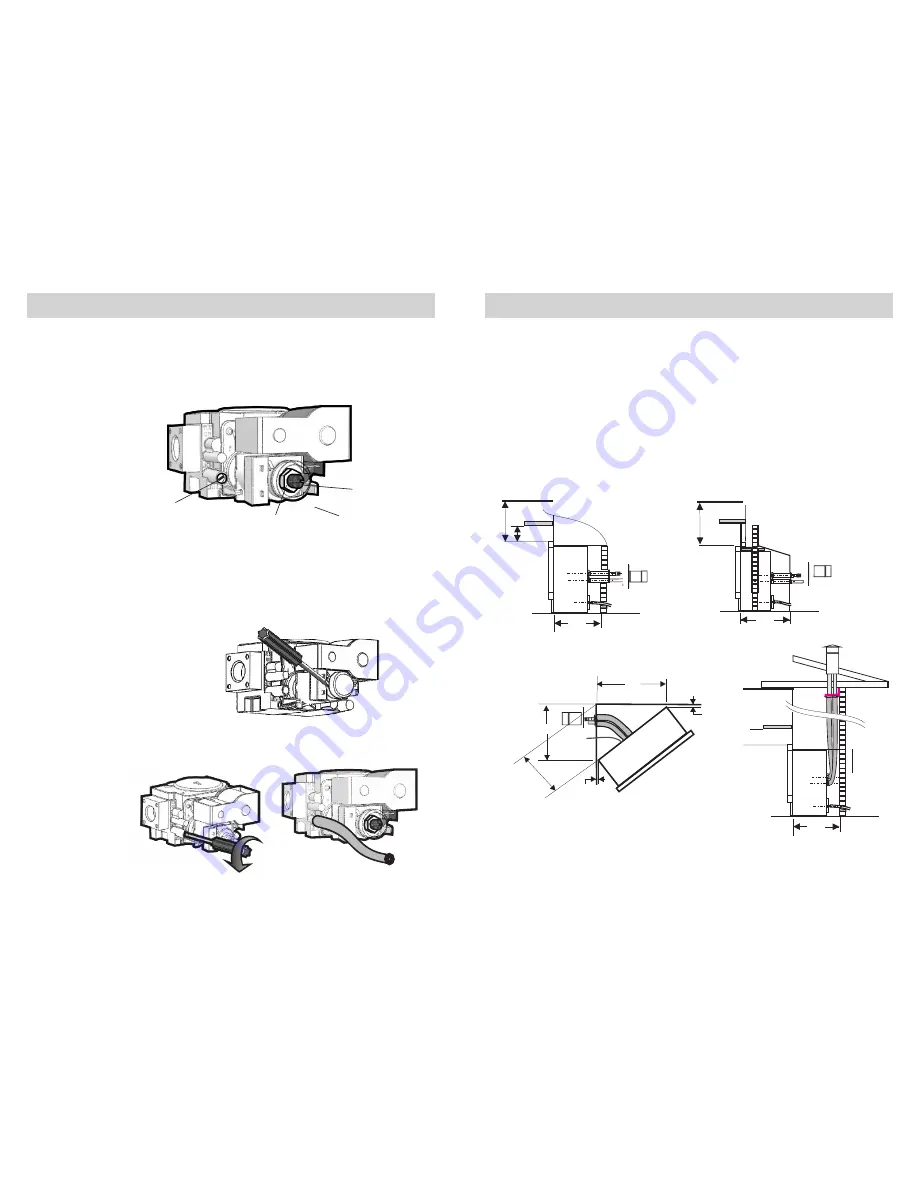

23. Gas control layout is as indicated in figure 23.

Pressures for ‘Burner full on’ and ‘Burner low flame’ are factory

set, however if pressures need to be checked or adjusted follow the

procedures described below and on the next two pages.

To check control outlet pressure at burner ‘Full on” and ‘Low Flame”

positions remove the plastic cap from the regulator adjustment location

as indicated in figures 24 .

Gas pressure point

24. The pressure point is closed with a captive screw. Turn screw 6 revo-

lutions anticlockwise to open the pressure point as indicated on figure

25 (a) and place manometer tube over the test point as per figure 25(b).

Important: To

achieve the correct

visual flame effect:

On Propane the gas

pressure must be set

at 2.65 kPa with

burner operating on

maximum setting.

On Natural Gas the

gas pressure must

be set at 0.75 kPa

with burner operat-

ing pressure on

maximum setting.

Plastic Cap

Pressure adjustment

(Burner ‘Full on’)

Burner adjustment

(Burner ‘Low flame’)

Pressure test point

with captive screw

485 min

300

1000 MIN

TO CEILING

485 min

TO CEILING

1000 MIN

MASONARY

FIREPLACE

APPLICATION

THROUGH WALL

APPLICATION

TIMBER or BRICK

*1*

*1*

*2*

*2*

CONSULT

MOCK FIRE

INSTRUCTION BOOKLET

REQUIREMENTS

FOR THIS APPLICATION

FLUEING OPTIONS

517

517

25

min

383

CORNER WALL

APPLICATION

*1*

*2*

CONSULT

MOCK FIRE

INSTRUCTION BOOKLET

REQUIREMENTS

FOR THIS APPLICATION

25min

*1* For any horizontal application top hat section can be removed.

*2* Condensation drain must have sufficient fall to provide adequate drainage.

ensure no water traps occur in drain.

585 min

Vertical flue installation -

using extended flue kit code

FLUEWFX

* 2*

11

FIG 8.

FIG 25a.

FIG 24.

FIG 23.

FIG 25b.

The heater is supplied with components to suit a horizontal flue coming

through a wall at the back of the heater. The Components include a flue cowl

which is designed to be fitted to the outside wall with suitable fasteners.

Condensate drain tube 2m and Clamp, and flexible tube sealant.

Flexible ducting is provided to attach the heater to the flue cowl. The use of

this ducting provides for some flexibility in the manner the flue and intake air

are connected.The flue and air intake components are fully attached to the

heater prior to the heater being fitted into the cavity.

When flueing the through the roof the Extended Flue Kit is required code

FLUEWFX. The maximum length of flue pipes that can be used with the

Powerflue heater is 6.0m.

The Cannon appliance is warranted against defects in materials and

Warranty service, which includes parts and labour for the replacement or

repair of defective parts, is available through the CANNON distributor.

(Details below or on page 24).

Consumers are responsible for service person’s travel outside normal

service areas (approximately seventy (70) kilometer radius from the nearest

Cannon dealer’s location), local transport costs, or any preventative

maintenance works as described in

Any product subjected to misuse, abuse, negligence, accident or alteration

will have its warranty voided. The defacement of serial plate will also void

warranty.

If installation is not carried out in accordance with manufacturer’s

instructions, this warranty may be void.

The customer must keep their “Tax Invoice” as proof of purchase of this

product and compliance certificate as proof of required installation.

workmanship for a period of two (2) years from its date of original

purchase, applicable only for residential use in Australia.

this manual.

Enter the details of the date installed and the Compliance Certificate

number in the appropriate area on the rear page of this manual.