(mm)

p.

2

0

20

-

M

an

u

al

c

od

e:

11

9

G

F

8

8

11

9

G

F

8

8

ve

r.

1

.0

1.

0

0

5

/2

0

12

© C

A

M

E C

an

ce

lli

A

uto

m

ati

ci

S

.p.

A

. - T

h

e d

ata a

n

d i

nf

or

m

ati

on i

n th

is

m

an

u

al

m

ay b

e u

p

d

ate

d at a

ny ti

m

e by C

am

e C

an

ce

lli

A

uto

m

ati

ci

S

.p.

A

. w

h

ic

h i

s u

n

d

er n

o o

b

lig

ati

on

to n

otify s

ai

d u

p

d

ate

s.

ENGLISH

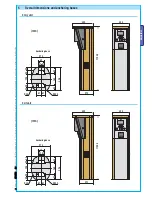

10.1 Setting up the entry unit and exit unit bases

The following illustrations are mere examples, in that the space required for anchoring the entry/exit unit and accesso-

ries varies depending on the overall dimensions. It is the installer's responsibility to choose the most suited solution.

- Assemble the four anchoring clamps to the plate.

- Dig a pit to house the anchoring plate (see drawing and

measurements at “Overall dimensions and anchoring bases”)

measuring at least 350 x 300 x 250 mm and lay any required

corrugated tubes for connections coming from the junction pit.

N.B. the number of tubes depends on the type of installation

and accessories used.

- Remove any protruding nuts or washers, position the cabinet onto the base and

fasten it.

Note: install the cabinet with the inspection fl ap facing an easily accessible direction.

- Fill the pit with concrete* and sink in the anchoring base (= plate +

anchor brackets). Make sure the corrugated tubes pass through the

specifi c hole in the plate and they do not fi ll with concrete. The base

must be perfectly level, clean and with the bolt threading completely

on the surface.

Wait at least 24 hrs for everything to solidify.

10

Entry unit - exit unit - installing

M12 UNI 5588 nut

M12 x 40 UNI 5739 bolt

Washer

*SUGGESTED CEMENT CHARACTERISTICS

The cement must be slump resistant tested by lowering the Abrams cone by

between 4 and 7 cm (for a conical shaft die 30 cm tall, with 10 cm diameter in

the high part and 20 cm in the low part) and the fi lling of which must be done in

four layers.

BONDING AGENTS: Use artifi cial Portland cement with no CPA 325 type

constituents.

AGGREGATES: 10/20 caliber and composed of either clay and salt free limestone

or silicon.

DOSAGE: 350 Kg/m³ .