5)

Selector for minimum flow temperature at heating start-up

(Tmin Y).

Adjustable from 20°C to 40°C.

Factory setting: 20°C.

6)

Maximum limit temperature selector.

Adjustable from 35°C to 65°C.

Factory setting: 50°C

In case a higher value has been set at point 7 of the front panel,

this will be restricted to the limit value.

7)

NZ

Neutral zone regulation selector.

Adjustable from 1,5°C to 6°C.

Factory setting: 2°C (equivalent to ±1°C).

If the flow temperature variation remains within the temperature

value selected in the neutral zone, the mixing valve remains

inactive.

When cooling, the neutral zone automatically takes the value 1,5°C.

8)

RF(%)

Return sensor regulation selector.

Adjustable from 0% to 100%.

Factory setting: 80%.

This selector is used to optimise the system output according to

the difference in temperature between flow and return (

∆

T).

∆

T is calculated as a percentage of the flow temperature

calculated on the characteristic curve.

∆

TY = (T

flow

set Y-Tmin Y)

∆

T =

∆

TY · %set · 0,3.

T

return

set Y = T

flow

set Y -

∆

T.

Example with factory setting values:

flow temperature calculated on the characteristic curve,

T

flow

set Y = 40°C (project conditions).

Thus:

∆

TY = (40 - 20) = 20°C

∆

T = 20 · 0,8 · 0,3 = 4,8°C

T

return

set Y = 40 - 4,8 = 35,2°C.

If the return temperature measured (T

return

Y) is

≠

T

return

set Y, the controller will modify the characteristic curve, moving

it upwards or downwards, to move the return temperature to the

set value.

This continuous comparison prevents room overheating caused

by gratuitous heat sources modifying the heating load.

There is no effect on the cooling function.

Curve with return temperature regulation

9)

Auxiliary contact. This contact opens when the mixing valve is

completely closed to the secondary and open to the primary.

It can be used to shut down the pump of the primary circuit or

the boiler.

10)

UR

Relative humidity sensor wiring. This sensor is used to

detect the limiting value of relative humidity to prevent

condensation on the cooling surface.

This is calibrated for RH= 80÷85%. When the calibrated value

is reached, this will cause the following state: mixing valve

closed, pump ON.

If various zones at risk of condensation are to be controlled, the

humidity sensor must be connected to a suitable interface kit

(transformer, converter and humidity sensor). Up to 12 converters

plus sensor can be connected to a single transformer.

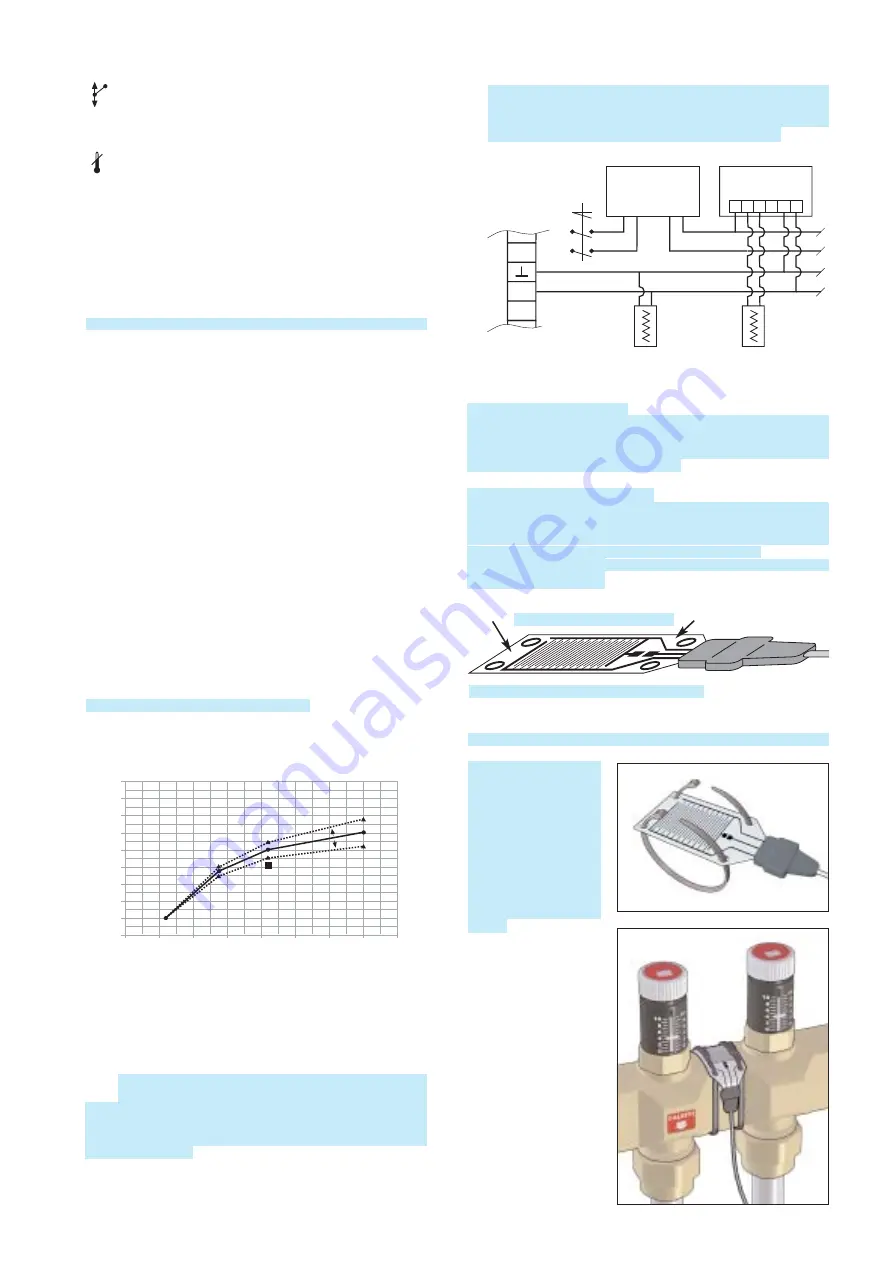

Humidity sensor control

At the start of each cooling season, the operating condition of the

sensor should be checked by placing a damp pad on its surface;

this operation should cause the mixing valve to close and the yellow

LED, point 1 on the front panel, to light.

Positioning humidity sensor

The umidity sensor must be positioned at the point where there is

most risk of the formation of condensation, depending on the

characteristics of the system. It must be positioned with the printed

part upward, according to the diagrams shown below.

Fix ends E, taking care that the central part adheres perfectly to the

manifold or to the piping.

Layouts for the correct positioning of the max RH% limit sensor.

The sensor should be

fixed to the manifold

installed in the position

where the RH% relative

humidity value has not

to exceed the safety

limits. Fixing in ensured

by inserting the two

straps contained in the

package through the

suitable holes on the

sensor.

15

20

25

30

35

40

45

50

55

60

25

20

15

10

5

0

-5

-10

-15

T

FLOW

(

°

C)

T

OUTSIDE

(

°

C)

Treturn 35,2

°

C

LH side

ter

m

inal strip

0

1

N

L

UR

SENSOR RH%

code 150050

SENSOR RH%

code 150050

1 2 3 4 5 6

CONVERTER

code 150051

TRANSFORMER

code 150052

24 V

220 V

SR

Upper side: printed circuit

Lower side: sited on the cooling surface

E

E