10

D.

Examination of Flue Product Carrying Areas

.

1.

Boiler

Flue passageways in the boiler sections should be

checked annually for any blockage or accumulation

of soot. A think layer of soot on the flue gas

passageways will affect heat transfer substantially.

The resultant loss in efficiency will have a direct

bearing on increased fuel consumption.

Blockage of the flues is hazardous. If severe, carbon

monoxide concentrations could be lethal during the

burning cycle. Flames could roll outside the jacket

creating a fire hazard. The heat concentration could

severely damage the base, warp the burners, melt

the pilot tubing and wire insulation and destroy the

ignition module inside the jacket vestibule.

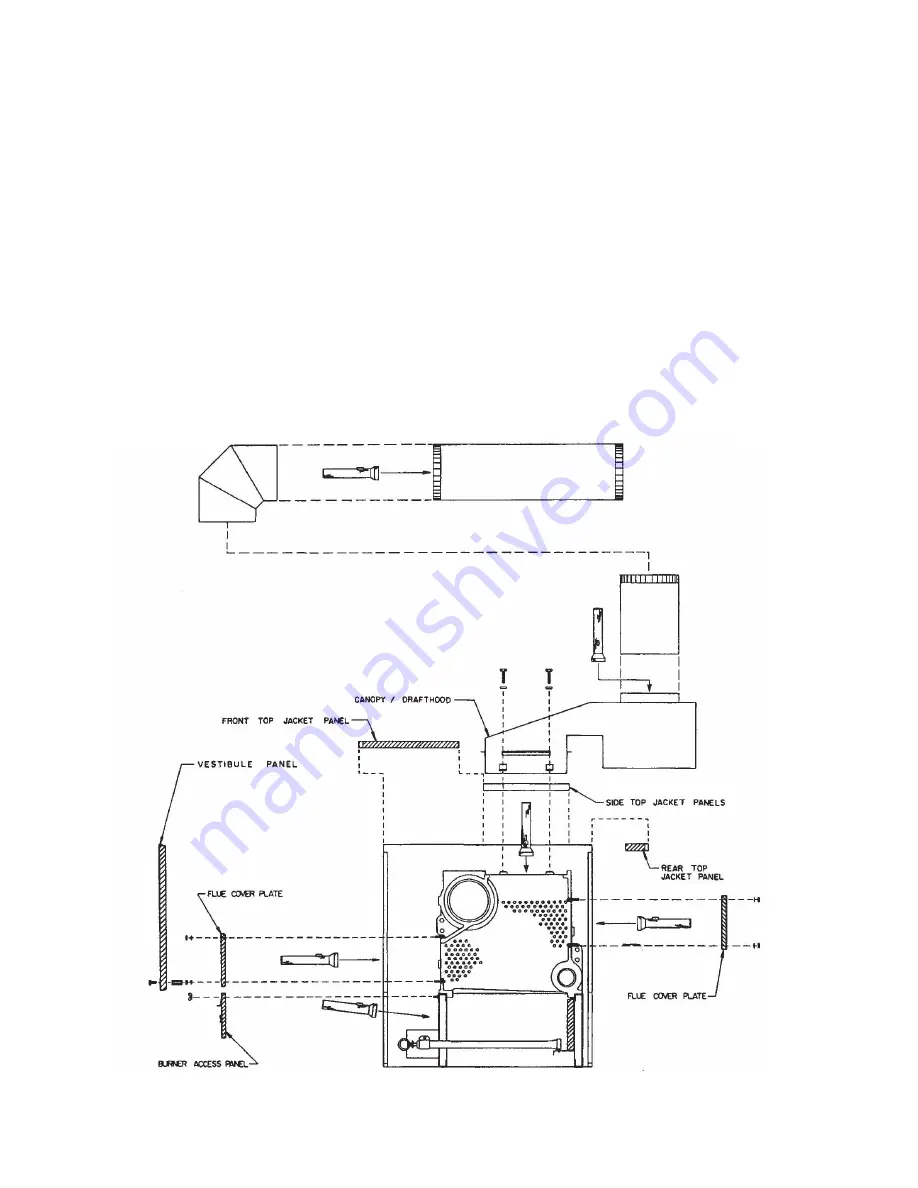

To obtain access to the flue cleanout panels, which

are installed on both the front and rear of the boiler,

the upper front and upper rear jacket panels must be

removed.

If access to the flue cleanout panels facing the front

of the boiler is required, the front vestibule panel

must be removed. See Figure 11.

Remove the Front Cleanout Panels first by removing

the upper and lower nuts and washers securing these

panels to the boiler sections, see Figure 11.

CARE SHOULD BE EXERCISED IN

REMOVING THE CLEANOUT PLATES FROM

THE BOLTS SO THAT THE INSULATION IS

NOT DAMAGED. IF DAMAGED, ALL EDGES

OF THE CLEANOUT PLATES SHOULD BE

SEALED WITH BOILER PUTTY WHEN

REINSTALLED UNTIL INSULATION CAN BE

REPLACED.

Using a flashlight, examine all flue passageways. If

passageways are free of soot and obstruction, it is

not necessary to remove the rear cleanout panels.

If the flues need cleaning or are obstructed, call a

qualified service agency.

Figure 11: Inspection of Boiler Flueways