14

DO NOT trap the drain line in any other location than at the

condensate drain trap supplied with the furnace. If possible, DO

NOT route the drain line where it may freeze. The drain line must

terminate at an inside drain to prevent freezing of the condensate

and possible property damage.

Special precautions MUST be made if installing furnace in an area

which may drop below 32

_

F (0

_

C). This can cause improper

operation or damage to the equipment. If the furnace environment

has the potential of freezing, the drain trap and drain line must be

protected. In areas where the temperature may be below 32

_

F (0

_

C), a Condensate Freeze Protection kit is required.

The kit

includes a condensate trap with heat pad and replaces the

factory--installed condensate trap. Refer to the Accessory section

of the Product Data for current kit number. A self--regulating,

shielded and waterproof heat tape rated at 3 to 6 watt per foot (10

to 20 watt per meter) at 115 volt, 40

_

F (4

_

C) may be used to

provide freeze protection of the remaining condensate drain line.

Wrap the drain trap and drain line with the heat tape and secure

with appropriate plastic ties. Follow the heat tape manufacturer’s

recommendations. Prime the trap before furnace operation.

The condensate drain line must be supported and/or secured per

local codes. Supports and clamps should be spaced to prevent the

drain line from sagging or being dislocated from the furnace or

termination point. In the absence of local codes, consult the current

edition of the National Standard Plumbing Code, in the U.S. or the

National Plumbing Code of Canada in Canada.

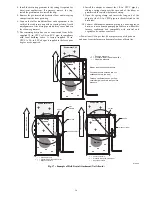

Upflow/Downflow Orientation

In the Upflow or Downflow orientation, the condensate trap is

inside the furnace casing. The condensate drain must be routed

from the trap through the furnace casing. The condensate drain can

be routed through the left or right side of the casing. (The left or

right side is as you are viewing/facing the furnace from the front.)

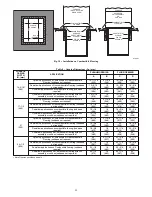

An indoor coil condensate drain or humidifier drain can be

connected to the external furnace condensate drain provided:

a. The drains are not hard piped together, and

b. There is an air gap at the point where the two drain lines

meet or

c. All condensate piping is at least 3/4-in. PVC and there is

a relief tee at the top of condensate drain piping as shown

in Fig. 18.

NOTE

: On narrower casings, it may be easier to remove the

condensate trap, connect the drain line components and re-install

the condensate trap. Read the steps thoroughly to familiarize

yourself with the required steps.

CUT HAZARD

Failure to follow this caution may result in personal injury.

Sheet metal parts may have sharp edges or burrs. Use care and

wear appropriate protective clothing, safety glasses and gloves

when handling parts, and servicing furnaces.

CAUTION

!

L12F019B

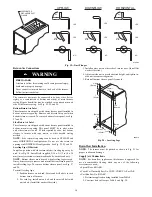

Fig. 13 -- Knockout Removal

For Right Side Condensate Drain:

1. Remove the 7/8--in. knock--out from the right side of the

casing. See Fig. 13 for suggested knockout removal tech-

nique.

2. Remove the pre--formed rubber drain elbow and two spring

clamps from the loose parts bag.

3. Slide a spring clamp 1--inch (25 mm) down the plain end

(the end without the formed grommet) of the drain elbow.

4. From inside the casing, insert the formed grommet end of

the elbow through the 7/8--in. knockout in the casing.

5. Pull the grommet through the casing from the outside until

it is seated in the knockout

6. Attach the plain end of the drain elbow to the outlet stub on

the drain trap. Secure the drain elbow to the trap with the

spring clamp.

The remaining drain line can be constructed from field supplied

1/2--in. CPVC or 3/4--in. PVC pipe, in compliance with local

building codes. A factory--supplied 1/2--in. CPVC to 3/4--in. PVC

adapter is supplied in the loose parts bag for use as required.

7. Install the adapter or connect the 1/2--in. CPVC pipe by

sliding a spring clamp over the open end of the grommet on

the outside the furnace casing.

8. Open the spring clamp and insert the long end of the

adapter or the 1/2--in. CPVC pipe into the outlet stub on the

drain tube.

9. Connect additional condensate piping to a code--approved

drain, or to a condensate pump approved for use with acidic

furnace condensate and compatible with mineral and

vegetable oils, such as canola oil.

Allow at least 1/4-in. per foot (20 mm per meter) of slope down

and away from the furnace in horizontal sections of drain line.

TIP FROM CONTRACTORS

: Contractors have found that

temporarily removing the inducer assembly in upflow applications

while performing the steps, below, makes upflow left--side drain

connections easier.

For Left Side Condensate Drain Connection:

1. For left side condensate drainage, the drain line is routed

from the condensate trap, behind the inducer (upflow) or

gas valve (downflow) and out through the left side of the

furnace casing. A pre-formed 1/2--in. CPVC “Z-pipe” is

provided with the furnace. The Z-pipe is long enough to

extend across the casing for drain connections.

2. Locate the Z-pipe. Remove the pre-formed drain elbow and

four spring clamps from the loose parts bag.

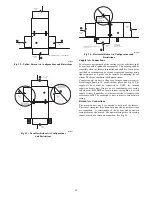

3. The Z-pipe is connected to the condensate trap and the

outside of the furnace by modifying the formed rubber

drain elbow as shown in Fig. 14.

4. Remove the formed grommet from the rubber drain elbow

by cutting the elbow along the vertical line located about

1--3/8 in. (35 mm) away from the formed grommet. See Fig.

14.

DO NOT DISCARD THE FORMED GROMMET

OR THE RUBBER ELBOW

. Both of these pieces will be

used.

Assemble and route the drain line to the opposite side of the

furnace as detailed below:

5. Remove the knock-out from the left side of the casing. See

Fig. 13 for suggested knockout removal technique.

6. From the outside of the casing, insert the angled end of the

Z-pipe through drain hole in the left side of the casing and

behind the inducer or gas valve. Allow the Z-pipe to

temporarily rest on the blower shelf (upflow) or burner box

(downflow).

(NOTE

: When the inducer housing has been

removed to ease installation in upflow applications, this step

is not needed.)

7. After inserting the Z pipe through the casing, slide a spring

clamp over each end of the Z pipe.

8. From inside the casing, insert the short end of the formed

grommet cut from the rubber drain elbow through the

7/8-in. drain knockout in the casing.

Содержание 915SB

Страница 65: ...65 A190099 Fig 63 Service Label Information...

Страница 76: ...76 A190093 Fig 69 Troubleshooting Guide Cont...

Страница 77: ...77 344442 2 Rev C A190259 Fig 70 Wiring Diagram...