9

If the indoor temperature is above 80

_

F (26.67

_

C), and the

outdoor temperature is in the favorable range, adjust system charge

by weight based on line length and allow the indoor temperature to

drop to 80

_

F (26.67

_

C) before attempting to check system charge

by subcooling method as described above.

If the indoor temperature is below 70

_

F (21.11

_

C), or the outdoor

temperature is not in the favorable range, adjust charge for line set

length above or below 15ft (4.57 m) only. Charge level should then

be appropriate for the system to achieve rated capacity. The charge

level could then be checked at another time when the both indoor

and outdoor temperatures are in a more favorable range. This

ensures maximum efficiency and reliability.

Step 13 — Pumpdown

If this system requires a Pumpdown for any reason, the procedures

below must be followed:

Because this system has an inverter controlled, compressor, and a

suction pressure transducer conventional procedure cannot be used

to “pump down” and isolate the refrigerant into the outdoor unit.

The wall control has provisions to assist in performing this

function.

1. Connect gages to 180CNV liquid and vapor or suction cap-

illary service ports to monitor operating pressures during

and at completion of the procedure.

2. In the advanced menu of the wall control, go to Refrigerant

Charge > Pumpdown

3. Select mode to pump down in COOL. COOL mode allows

refrigerant to be isolated in outdoor unit. Set desired time

period. Default time period for the procedure is 120 min-

utes.

4. Select Start on wall control to begin the pumpdown process.

Unit will begin running in selected mode after a brief delay.

5. Close the liquid service valve.

6. The unit will run in selected mode with the low pressure

protection set to indicate pumpdown is complete when the

suction pressure drops below 0 psig. Compressor protec-

tions are still active to prevent damage to the compressor or

inverter (high pressure, high current, high torque, scroll

temperature, etc.) .

7. Once system indicates pumpdown complete or failure to

complete shutdown, close vapor service valve.

8. If pumpdown does not complete due to compressor safety

shutdown, a recovery system will be required to remove fi-

nal quantity of refrigerant from indoor coil and line set.

9. Remove power from indoor and AC unit prior to servicing

unit.

MAJOR COMPONENTS

Variable speed Control Board

The AC control board controls the following functions:

S

Compressor speed

S

Contactor operation

S

Outdoor fan motor operation

S

Low ambient cooling

S

Crankcase heater operation

S

Pressure switch monitoring

S

Time Delays

S

Pressure Transducer

S

Inverter communication and control

Inverter

The inverter is located inside the control box. This is an air--cooled

device that communicates with the control board and drives the

compressor to the demanded RPM. When the contactor closes, it

powers the inverter with line voltage. The inverter changes the line

voltage to 410 volts DC 3--phase, and varies the frequency to drive

the compressor at the desired RPM.

NOTE

: Manually closing the contactor will not cause the unit to

operate. The unit must be operated with an Evolution Control. A

standard thermostat will allow operation only in the emergency

mode (high speed heating or cooling).

Variable Speed Compressor

This unit contains a variable speed compressor that has a wide

operating range. It operates on 410vdc provided by the inverter.

This compressor can only be operated by the specific inverter

supplied with the unit.

EQUIPMENT DAMAGE HAZARD

Failure to follow this caution may result in equipment damage

and/or improper operation.

Do not attempt to apply line voltage directly to the

compressor. This will destroy the compressor.

CAUTION

!

Field control Connections

For normal operation use the ABCD Evolution connections only.

Only two wires, AB are required. See Fig. 14. Discrete inputs (Y,C,

O) are available for emergency operation if the Evolution Bus is

not in operation.

Pressure Transducer (SPT)

A 5 VDC output low pressure transducer that provides a 0--5 VDC

data for interpretation by the control board for a 0 to 200 psig

range of pressure at the suction tube. This interpreted pressure data

is then intelligently used by the control board for low pressure

cut--out, loss of charge management, compressor overall envelope

management, oil circulation management and lubrication

management. (See Fig. 13.)

Compressor Control Contactor

The contactor has a 24 volt coil. The electronic control board

controls the operation of the contactor.

TROUBLESHOOTING

Systems Communication Failure

If communication with the Evolution control is lost with the User

Interface (UI), the control will flash the appropriate fault code (see

Table 7). Check the wiring to the User Interface and the indoor and

outdoor units and power.

Model Plug

Each control board contains a model plug. The correct model plug

must be installed for the system to operate properly (see Table 3).

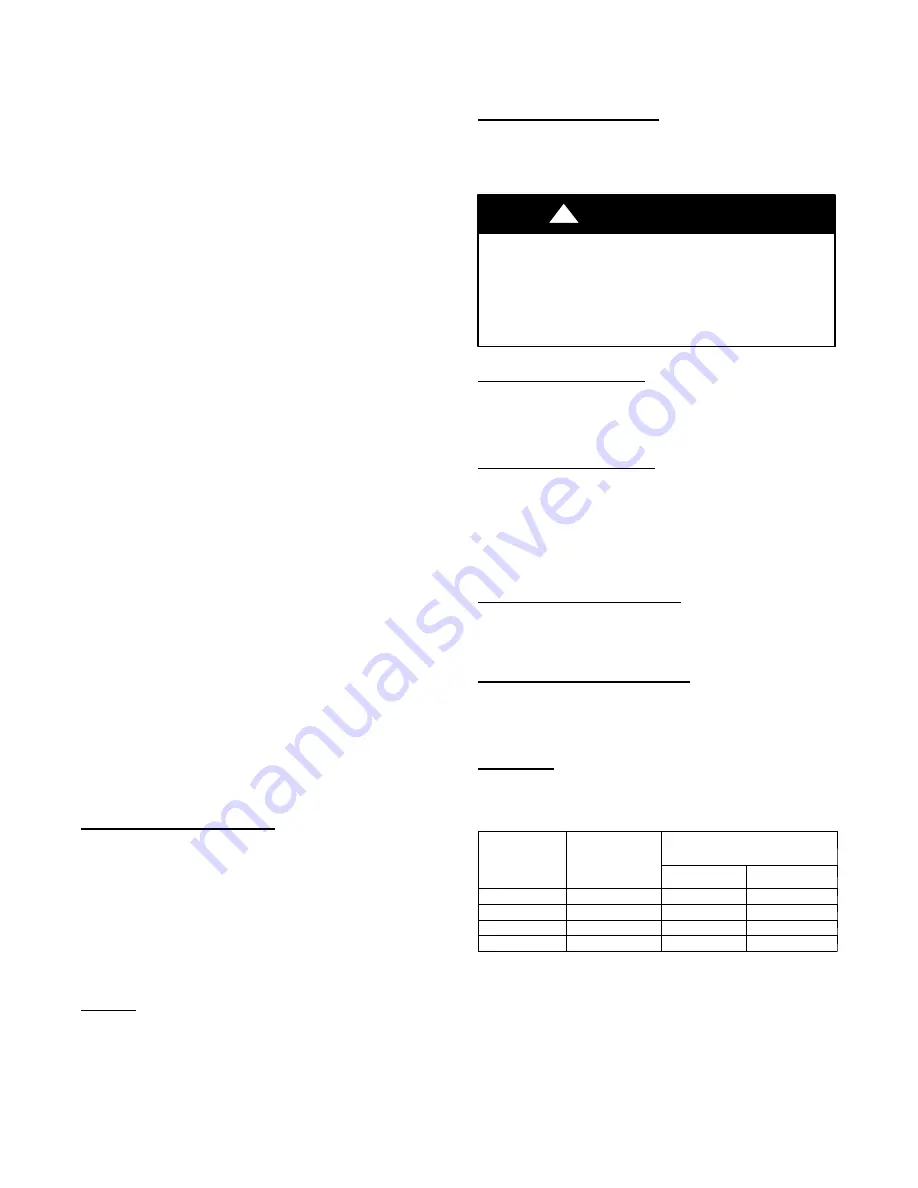

Table 3 – Model Plug Information

MODEL

NUMBER

MODEL PLUG

NUMBER

PIN RESISTANCE

(K---ohms)

Pins 1---4

Pins 2---3

180CNV024

HK70EZ011

5.1K

150K

180CNV036

HK70EZ012

5.1K

180K

180CNV048

HK70EZ013

5.1K

220K

180CNV060

HK70EZ014

5.1K

270K

The model plug is used to identify the type and size of unit to the

control.

On new units, the model and serial numbers are input into the

board’s memory at the factory. If a model plug is lost or missing at

initial installation, the unit will operate according to the

information input at the factory and the appropriate error code will

flash temporarily. An RCD replacement board contains no model

and serial information. If the factory control board fails, the model

plug must be transferred from the original board to the replacement

board for the unit to operate.

Содержание 180CNV024

Страница 14: ...14 Table 7 Troubleshooting...