8

SYSTEM DUCTWORK DESIGN

This installation should be performed by a qualified installer. Observe general rules

and the applicable parts required for a safe installation. Observe all local and state codes

during installation.

Since all buildings are different, you must select the most adaptable installation for

your building. There are many different installation methods available to you. You may

prefer a wall-mounted discharge, heat pump, central air tie in, under floor/attic installa-

tion or new ductwork design.

WALL MOUNTED SYSTEM

When penetrating your structure, cut the opening 2” larger than the duct size.

Insert the duct through the wall, insulate the duct thoroughly if it may come in contact

with any combustional materials. Install metal flashing on the outside around the duct-

work and fill any voids with loose insulation and install another metal flashing on inside

wall. Caulk outside flashing with a good quality silicone sealer.

HEAT-PUMP/ CENTRAL HEAT SYSTEM

Using the same structure penetrating method mentioned above, attach the hot air

duct from The Bryan Furnace to the down stream side of the hot air plenum or hot air

duct of your existing system. Insure that hot air from The Bryan Furnace is not delivered

so that it passes through the air conditioning coil. Attach the hot air duct to the hot air

plenum or ductwork with an elbow at an angle so that hot air from The Bryan Furnace is

delivered down stream from the central system. Run the return air duct separate from

the return air from your central system or the hot air from The Bryan Furnace may try to

short circuit back through the central system.

NEW DUCTWORK SYSTEM

If possible, run your ductwork under the floor to deliver heat at floor level, or into

the attic where you can locate outlets at an area of your choice. With the Model 450, try

to avoid duct length of over 100 feet. With any furnace the farther the length and more

turns and branches you use, the less efficient your unit will perform. Try to avoid 90 de-

gree turns. If the ductwork is to be located in a conditioned area, insulation is not re-

quired from the wall penetration to any penetrations through a wall of combustion mate-

rial.

MAINTENANCE

UNIT– Keep the unit clean for extended life. Promptly paint over any rust spots which

may appear on the galvanized surfaces with cold galvanizing spray paint available at hard-

ware stores, heating & cooling supply stores, etc.

FAN- Warning: always disconnect the electrical supply to the furnace before exposing the

fan and electronics for maintenance. Yearly, remove the fan box access panel and visually

inspect the wiring connections, automatic damper operation, and remove any debris that

may be pulled into the area by the return air or combustion air fan. Periodically remove

the return air duct at the fan box and clean the squirrel cage to maintain fan efficiency.

PARTS- Contact your dealer or factory for parts. Simply state the model furnace and

parts desired. Defective parts must be returned to dealer if it is a warranty item.

8

8

Содержание 450

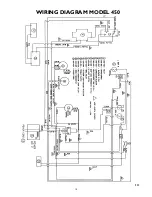

Страница 14: ...14 WIRING DIAGRAM MODEL 450 14 ...

Страница 19: ...19 MODEL 450 MODEL 300 MODEL 350 ...

Страница 21: ...21 ...

Страница 22: ...22 ...

Страница 23: ...23 ...