5

OPERATING INSTRUCTIONS

TEMPERATURE ADJUSTMENTS

A solid fuel burns cleanest in an environment with an unlimited supply of oxygen.

Allowing a fire to burn this way

,

however produces a short , very hot fire with most of the

released heat going up the flue and the extreme temperatures causing a safety hazard and

possibly damaging the furnace. On the other hand, a smothered fire produces an ex-

tremely long, smoldering burn which is inefficient and produces large quantities of soot or

creosote with the danger of a clogged flue or stack fire. Temperature adjustments are

made by adjusting the inside the building wall mounted thermostat provided with your

Bryan Furnace, and never by opening either the loading or ash door. Temperature

changes are not noticed immediately and may take 15 to 30 minutes between adjustments

to allow the fire to reach equilibrium at the new setting.

ASH REMOVAL

Turn indoor thermostat to the off set-

ting, open the ash door slightly for a few sec-

onds before servicing to allow smoke to clear.

Ashes should be removed frequently.

The ash door should not be opened

with a full load of burning wood as this allows excess combustion air to enter the chamber

and can cause overheating.

After unit has cooled down, open the ash door, remove the ash pan using protective

gloves and place ashes in acceptable noncombustible container.

Do not leave the ash door open while emptying ashes as this allows uncontrolled

combustion air to enter the chamber and can cause overheating. NEVER leave the ash

door open with a hot fire going as this can cause the grates to warp.

CREOSOTE AND SOOT FORMATION AND NEED FOR REMOVAL

When wood is burned slowly, it produces tar and other organic vapors, which com-

bined with expelled moisture may form creosote. The creosote vapors condense in the

relatively cool chimney flue of a slow burning fire. As a result creosote residue accumu-

lates on the flue lining. When ignited, this creosote makes an extremely hot fire. The

chimney connector and chimney should be inspected monthly during the heating season to

determine if a creosote buildup has occurred. If creosote has accumulated, it should be re-

moved to reduce the risk of a chimney fire. Be aware that the hotter the fire the less creo-

sote is deposited. Weekly cleaning may be necessary in mild weather while monthly clean-

ings may suffice during the coldest months.

CAUTION

Never operate your furnace so that any

portion becomes red hot. This is danger-

ous as well as damaging to the furnace

CAUTION

Ashes should be placed in a metal container with a tight fitting lid. The closed con-

tainer of ashes should be placed on a noncombustible floor or on the bare ground, well

away from all combustible materials, pending final disposal. If the ashes are disposed,

by burial in soil or otherwise locally dispersed, they should be retained in the closed

container until all cinders have thoroughly cooled.

CAUTION

In the event of a chimney fire, close furnace doors, turn

off thermostat, call the fire department and leave the building safely.

5

Содержание 450

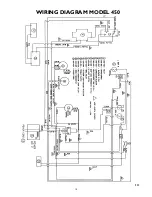

Страница 14: ...14 WIRING DIAGRAM MODEL 450 14 ...

Страница 19: ...19 MODEL 450 MODEL 300 MODEL 350 ...

Страница 21: ...21 ...

Страница 22: ...22 ...

Страница 23: ...23 ...