Form: 2435

Revision: 9

Free Flex Installation and Operation Manual

Date: 9-1-2017

Bryan Steam LLC, 783 N Chili Ave, Peru IN 46970

Web:

www.

bryanboilers

.com

Phone:

765-473-6651

Fax:

765-473-3074

Email:

13

3.2.6

Condensate Drain Connection

A condensate drain trap is shipped with the

boiler and is provided with a 1” nps

connection to drain the condensed products

of combustion from the boiler. Pipe with

continuous Teflon, high temperature silicone

tubing, or other tubing material compatible

with flue gas condensate. The condensate

temperature should never exceed 212

o

F and

the pH of the condensate should never have a

value lower than 3.5. NO VALVE is to be

installed in this line from the boiler to point

of discharge.

The condensate drain trap should be flushed

with water as part of your boiler maintenance

schedule to remove any debris that might

have accumulated over time.

A common condensate pump/sump may be

used. Run separate piping from each

condensate drain to the sump. A common

drain may be used to discharge condensate

from the sump. Consult pump/sump

materials of construction. If a common sump

is used, individual drain lines should be

connected such that one drain cannot back

feed into another drain. Use Table 3 for

sizing the pump / sump.

Table 3: Typical Condensate Flow Rate

Model

Max Condensate Flow (gph)

FF1000

7

FF1500

10.5

FF2000

16

FF2500

21.5

FF3000

27

Consult local authorities regarding disposal of

flue gas condensate into public waste water

system. Some jurisdictions require that

condensate be buffered before discharge. This

buffering is commonly achieved by draining

the condensate through a limestone bed.

Consult Bryan Steam or a chemical treatment

company for buffering system.

CAUTION

Failure to properly pipe the condensate

system will greatly reduce boiler life. Do

not install plugs, caps, or valves on

condensate piping.

Do not manifold boiler condensate and

vent drains together.

Do not crimp condensate lines or reduce

drain line inner diameter size.

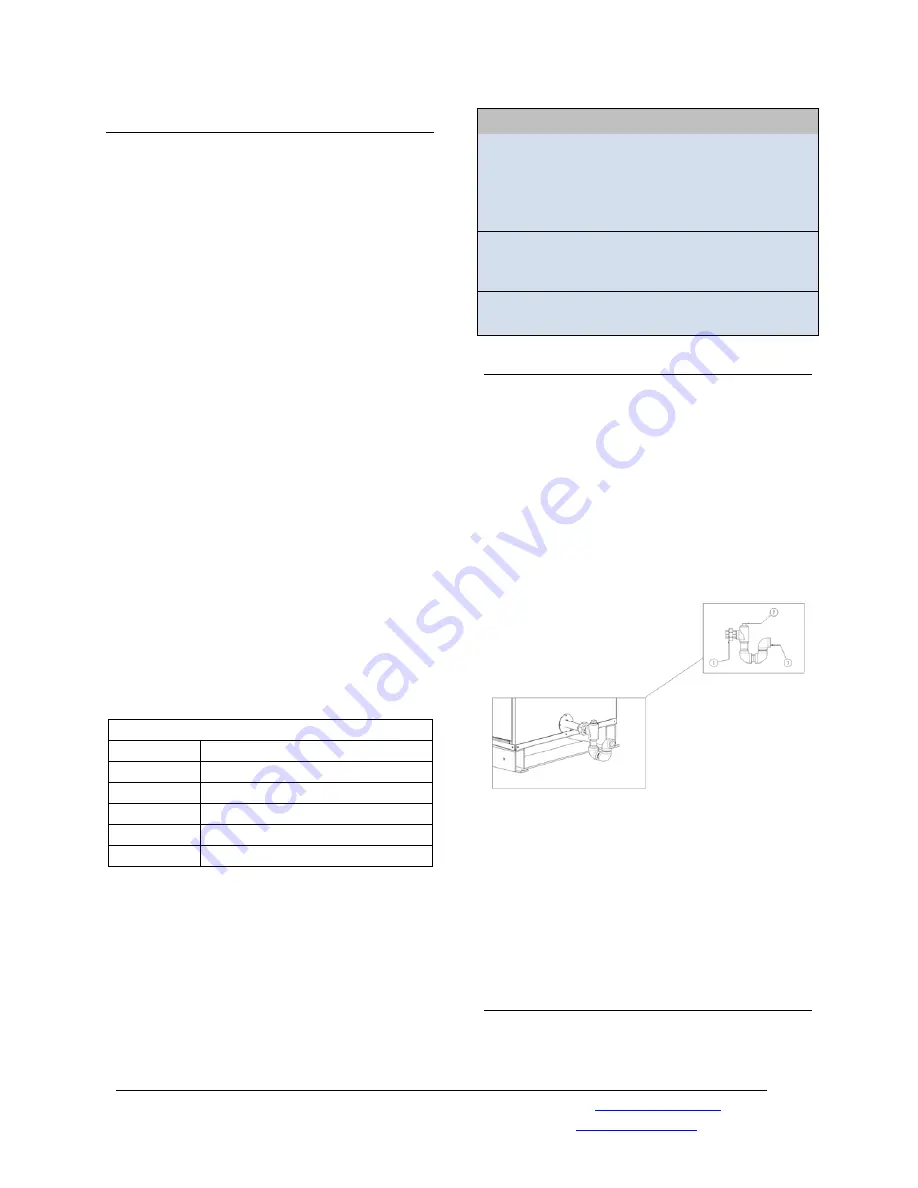

3.2.6.1

FF1000 Condensate Drain Trap

Ensure that the condensate drain trap is filled

with water prior to running the boiler to

prevent flue gas emission to the boiler room.

It is recommended that the personnel

responsible for running and maintaining the

boiler periodically check the water level in the

condensate drain trap bend, especially, when

the boiler is operating in a non-condensing

condition for an extended period of time.

Figure 4: FF 1000 Condensate Drain Trap

1. Union Connection to the boiler

condensate drain line

2. Removable cleaning plug

3. Condensate drain outlet connection

3.2.6.2

FF1500 – 3000 Condensate Drain

Trap