BrownDigital FireFly Technician’s reference

Cold After:

This controls the amount of time it takes for the

dryer to fully cool-down (inactive). This should

be set to have the longest cool-down time.

Warm After:

This controls the amount of time it takes for the

dryer to moderately cool-down (idle). In other

words, it is no longer hot (active), but it has not

fully cooled (inactive). This time should be set

shorter than the Cold After time.

The prewarm time directly affects the cure

quality for a product and the products to follow.

The longer the prewarm time, the closer the

system will get to reaching a product’s target

temperature. It also reduces the cure variation

between products using the same program. The

disadvantage is that some production time will

be lost at the beginning of each run (program

switch). Short prewarm times are beneficial in

situations where programs are consistently being

switched.

Similarly, the longer cool-down times (Cold

After and Warm After), the more accurate the

temperature will be to its target value. Shorter

cool-down times are applied if the majority of

products use the same program or if there is a

small gap between program temperatures.

Longer cool-down times are beneficial if there is

a large temperature gap between programs. For

example, a program is changed to one that is 60

degrees lower. A short cool-down time would

not give the system enough time to reach the

lower target temperature. This would cause the

first few products to be inaccurately cured, each

at varying temperatures. The disadvantage to

having long cool-down times is that the belt will

need to stop more frequently to execute prewarm

cycles.

To summarize, using short preheat times (5-10

seconds) and short cool-down times (10-20

seconds) can be beneficial in situations where

there are a large number of short runs. In other

words, after a program change, only a few

products need to run through before the program

needs to be switched again. Long preheat times

(10-30 seconds) and cool-down times (30-120

seconds) are beneficial in situations where there

are a small number of long runs. Meaning a lot

of products can be sent through using one

program, thus programs do not need to be

switched as often.

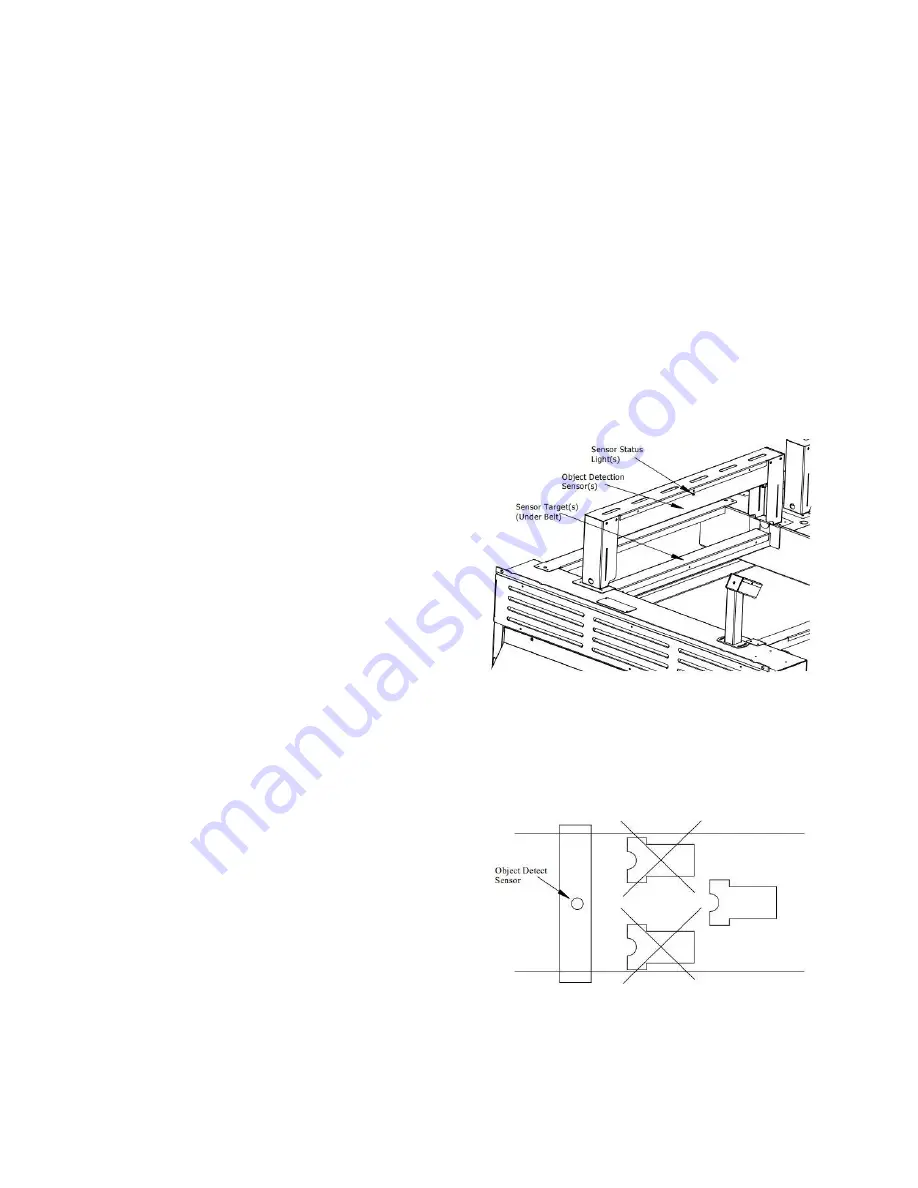

Object Detection:

The Firefly Curing System uses sensors at the

front of the heat chamber to detect objects

entering the dryer (Figure 12)

Figure 12: Object Detect Sensor(s)

Objects entering the chamber MUST trip the

sensor in order for the dryer to operate correctly.

Undetected products will not activate the

machine, and may result in uncured or under

cured ink.

Figure 13: Tripping Object Detect Sensor

The object detect sensor works by shining an

invisible (Infrared) beam of light down through

7

Содержание Firefly

Страница 8: ...BrownDigital FireFly set up guide Appendix A Firefly Machine Wiring Diagrams 6 ...

Страница 9: ...BrownDigital FireFly set up guide Figure A 1 1 Lane Firefly Machine Wiring Diagram 7 ...

Страница 10: ...BrownDigital FireFly set up guide Figure A 2 2 Lane Firefly Machine Wiring Diagram 8 ...

Страница 11: ...BrownDigital FireFly set up guide Figure A 3 3 Lane Firefly Machine Wiring Diagram 9 ...