Bronkhorst

®

9.17.057

page 24

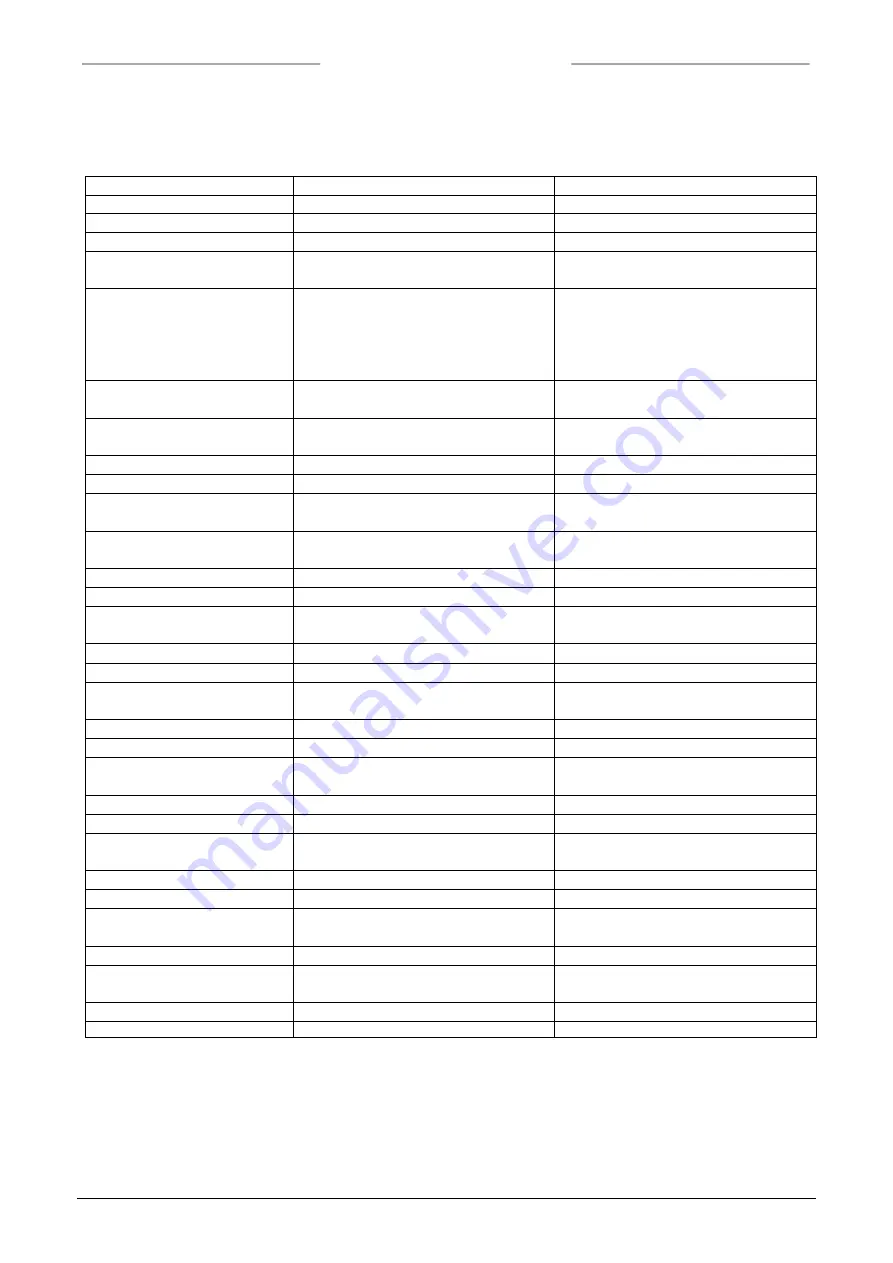

5.3 Troubleshooting summary general

Symptom

Possible cause

Action

No output signal

No power supply

Check power supply and hook-up

Check cable connection and hook-up.

Check status of LED’s

(see manual 9.17.023 chapter 10)

No setpoint

For analog used instruments measure

between pin 3 and 8 of sub-D9

connector.

For digital use make sure to perform a

read setpoint after sending

Cable damaged or hooked-up wrong

Check and compare signals at both ends

of cable.

PC-board damaged due to long lasting

shortage and/or high-voltage peaks

Return to factory

No or too low inlet pressure

Increase inlet pressure

Open shut-off at inlet and outlet

Supply pressure too high, or differential

pressure across meter too high

Reduce supply pressure

Valve blocked / contaminated

Set control mode to valve fully open

and check if it opens

Sensor / capillary failure

Return to factory

Maximum output signal

Leakage of control valve

Set control mode to valve close and

check if it closes

Sensor / capillary failure

Return to factory

Output signal much lower than

setpoint signal or desired flow

Incorrect type of gas or too low inlet

pressure

Test instrument on conditions for which

it was designed

Oscillation

Supply pressure / diff. pressure too high Reduce pressure

Pressure regulator of supply pressure is

oscillating or wrong sized

Replace pressure regulator

Controller adjustment wrong

Adjust controller with PID settings

Flow is gradually decreasing

Condensation, can occur e.g. with NH

3

Decrease supply pressure and / or heat

gas to be measured

Small flow at zero setpoint

Valve leaks due to damage or dirt

Return to factory

Increased zero reading without flow

caused by raised zero-point

Perform an auto-zero action

No digital communication

Occupied or wrong bus address

Change address with software or

rotary-switches

No or wrong bus termination

Check cabling and termination