page 4

TOOL LISTING

Depending on the installation, the use of the following tools

may be required. The power tools are recommended to make

the installation proceed quickly. A mask should be worn when

cutting ducting and gloves when using glue.

Wire strippers, 1/4’’ and 1/2” drill bits, utility knife, putty knife,

2½’’ hole saw, keyhole saw, hammer, cold chisel, level,

flashlight, drill, electrical tape, screwdriver, wrench, hacksaw,

tape measure, safety glasses.

WORKING WITH PLASTIC TUBING

CUTTING TUBING

Measure the length of tube needed. Allow 5/8” of tubing for

inserting into fittings and 1½” for placing into flexible tubing.

Cut the plastic tubing with a hacksaw, ensuring that the cut is

exactly square. Use wire cutters or tin snips to cut flexible

tubing, 8” lengths of flexible tubing should not be cut.

Use a small knife or steel wool to remove any burrs from the

inside of the tube.

Use a file to slightly bevel the outside of the tube so that it will

easily slide into the fitting. Use steel wool or a light grained

sandpaper to buff the surface of the tube which will be glued.

MAKING A JOINT

Insert the tube into the fitting,

aligning both parts as they will be

installed. Mark the tube and the

fitting to quickly realign the joint.

Apply cement in an inch-wide

band to the outside of the tube.

Insert the tube into the fitting with

the alignment marks a quarter

turn apart, and then quickly push

and turn the fitting to align the

marks and spread the cement.

Allow 1 minute for the joint to dry.

CEMENTING FLEXIBLE TUBING

Ensure the ends of the flexible tubing are even. When joining

flexible tubing to plastic tubing or to an inlet mounting plate,

apply cement to both the inside of the flexible tubing and the

outside of the plastic tubing or mounting plate tubing ring.

Twist both pieces while joining them to evenly spread the glue.

Allow 5 minutes for the cement to set in flexible tubing.

SECURE WIRE

TO TUBING

The low-voltage power wiring is

run along with the tubing. Use

electrical tape to secure the wire

to the tubing. Tape the wire

approximately every 12" to 18".

MAKING THE WALL INLET CUTOUT

The wall inlet should be located 18” on-center from the floor

and directly in line with the attic or basement inlet tubing hole

previously drilled in the wall plate or header. The wall inlet

cutout must be exactly 3⅞” high by 2⅞” wide.

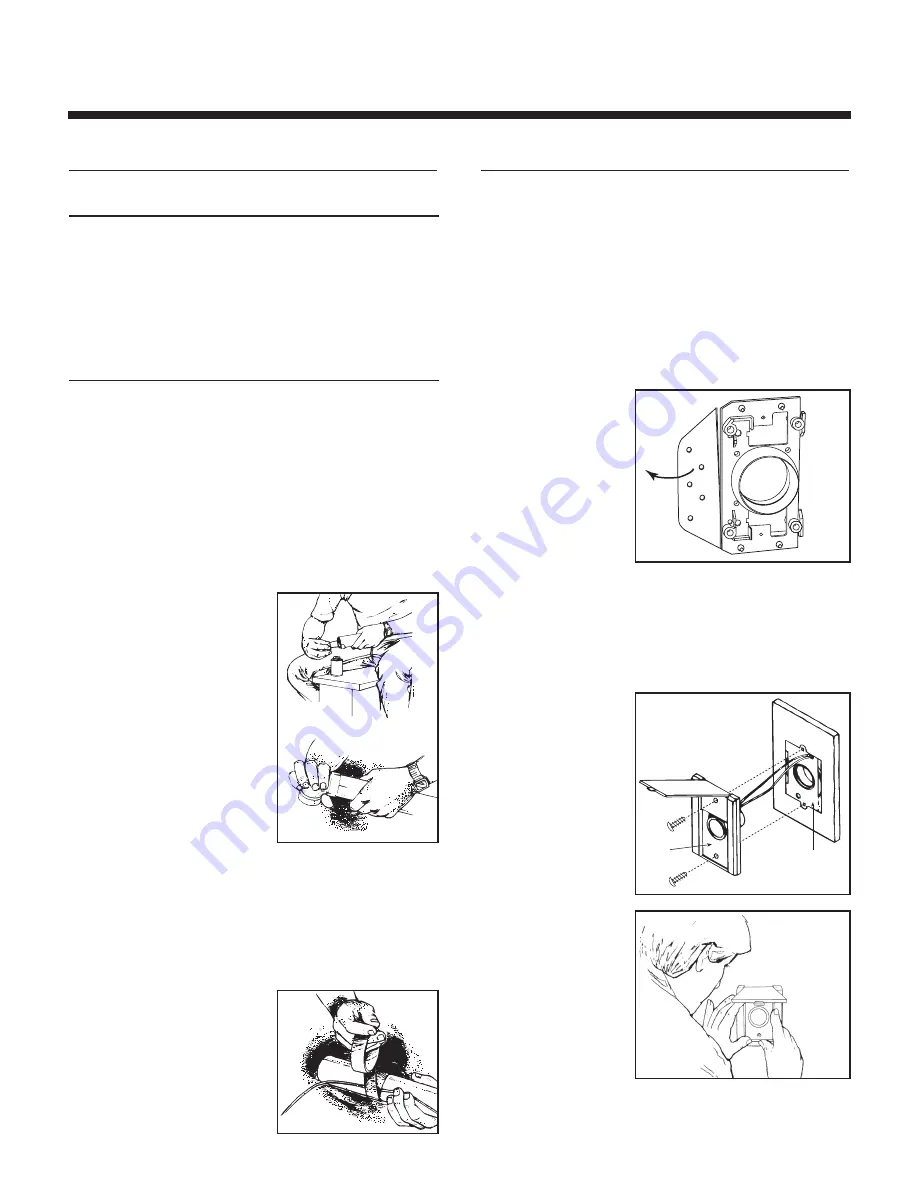

ATTACHING THE INLET MOUNTING PLATE

Reach through the inlet hole and locate the inlet tubing. Pull

the flexible tubing through the inlet hole and remove the

low-voltage wiring from inside the tube.

Remove the nail flange

from the inlet mounting

plate (

Fig. 1

). Apply cement

to both the inside of the

flexible tubing and to the

outside of the mounting

plate’s tube ring. Insert

the mounting plate’s

tube ring in the flexible

tubing and twisting the

pieces as you join them to spread the cement, and align the

mounting plate in a vertical position.

Now, strip the ends of the two low-voltage wires, and then

connect the wires to the screw terminals on the back of the

inlet cover. When the wiring is complete, assemble the inlet

cover to the tube guard and mounting plate.

COMPLETING

THE INLET

ASSEMBLY

Once you have attached

the mounting plate to the

flexible tubing, pull the

low-voltage wire through

the top wiring hole in the

mounting plate.

INSTALLING

THE INLET

Place the inlet into the

wall cutout (the inlet

cover remains on the

outside). Hold the inlet in

place and gradually

tighten down each screw

a little bit at a time.

For more details on inlet installation, visit www.broan.ca

for the Central Vacuum System Installation Instructions.

GENERAL INFORMATION

WALL INLET INSTALLATION

AR0040

INLET

MOUNTING

PLATE

AE0024A

AO0045

F

IG

. 1

AO0010

AO0011