25

5.

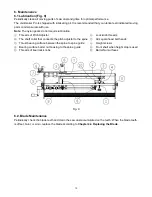

锯片垂直度及相对于台板运动平行度的校准(图 7-8)

推锯在出厂前已完成校准,但在运输过程中设备可能会受到影响,为了保证锯切的精确性,请在正式使

用前,按以下步骤进行校准:

注意:滑动台板前,需移除木质靠山,避免锯片在未校准前对靠山进行锯切。

1.摆动锯片,使图 7 位置的①处呈 90°状态,然后锁紧龙骨前后锁紧旋钮。

2.使用直角尺检查②③处的角度:

如均为 90°,进入步骤 3。

如位置②或③出现角度偏差,松开龙骨后锁紧旋钮,握住龙骨后端,轻微摆动龙骨,使锯片与台板呈 90°状

态。

●

重复步骤 1 和 2,直到位置①②③处的锯片均与台板垂直。

3.在锯片与台板垂直的状态下,检查指针,若指针未指向 90°,拧松指针锁紧螺丝,轻微拨动指针至 90°并

锁紧。

●

在锯片与台板垂直的状态下,锁紧龙骨前后锁紧旋钮,进行平行度的校准(以前端为基准进行校准):

4.在台板上放置一个内六角扳手(或者一张方形硬纸卡),一端轻触锯片,如图 8 所示。滑动台板,检查锯

片相对于台板运动的平行度。

5.如平行度存在偏差,略微松开龙骨后锁紧旋钮和两颗龙骨后固定螺丝以及对侧的一颗龙骨前固定螺丝,用

手固定住后耳轴,轻微敲击龙骨进行平行度调节,然后锁紧。

(根据个人操作习惯的不同,也可以后端为基准进行校准。)

●

重复步骤 1-5,直到满足要求。

如果想要获得高质量的精准锯切,校准是必不可少的,请在进行操作前,务必耐心完成该校准步骤。

图 7

图 8

台板行程

前面板

龙骨后锁紧旋钮

龙骨后固定螺丝

龙骨前锁紧旋钮

靠山锁紧块

龙骨前固定螺丝

后面板

前耳轴

后耳轴

龙骨后锁紧旋钮

直角尺

龙骨

1

2

3

指针锁紧螺丝

指针

龙骨前锁紧旋钮

Содержание JMPv2 Jointmaker Pro

Страница 1: ......

Страница 3: ...1 English Version...

Страница 17: ...15 8 Exploded View and Parts List...

Страница 19: ...17...

Страница 22: ...20 2 1 1 3 2 1 2 2 2 M5x80 M5 1 2 3 4 5 A x2 6 x1 7 x1 1 2 5 4 3...

Страница 23: ...21 4 5 4 1 3 3 1 25mm 3 3 1 2 1 2 3 4 2 3 3 1 25mm 1 2 3...

Страница 24: ...22 4 3 4 1 2 a 8 b c 4 4 4 4 5 1 2 3 5 4...

Страница 25: ...23 4 5 6 4 6 6 1 2 3 6...

Страница 27: ...25 5 7 8 1 7 90 2 90 3 90 1 2 3 90 90 4 8 5 1 5 7 8 1 2 3...

Страница 28: ...26 6 1 9 1 2 3 4 5 6 7 8 9 10 9 2 4 4...

Страница 29: ...27 7 1 2 3 4 5 6 7 1 5 2 2 3 3 4 5 4 5 4 4 6 7 5 4 2 4 4 4 4 4 1...

Страница 30: ...28 8...

Страница 32: ......