8

4.2 Adjusting the Blade Pitch (Fig. 3)

As shown in Fig.3, you can adjust the blade pitch by turning the blade pitch adjustment knob. (The Blade

Pitch increment of one turn is 0.05”)

Note:

1. If the pitch was set too aggressive, you may get your material stuck on the blade , which may ruin the

blade. When this happens, do not attempt to retract the stock by moving the tables backwards, try lowering

the blade directly out of the cut.

2. The very best practice is to start with a pitch that is too low and gradually increase it to an optimal pitch.

Please refer to the

Cutting Guide

on page 6 for more details.

3. The front blade teeth must be lower than the table while adjusting the blade pitch.

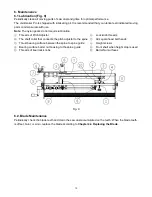

4.3 Adjusting the Blade Angle (Fig. 4)

Loosen the two keel lock knobs (the rear keel lock knob not shown in Fig.4), grasp the middle of keel and

swing to get the desired blade angle, then tighten the two keel lock knobs.

Note:

1. Before any cutting operations, make sure that the blade whose angle is adjusted will not interfere with

the fence.

2. After each adjustment of the blade angle, the parallelism between the blade and table travel should be

inspected and calibrated according to the following steps:

a. Position a hex key wrench (or a hard card) against the fence. Lightly touch the end of the wrench to the

leading edge of the saw blade (as illustrated in Fig. 8).

b. Slide the table slowly, inspect the parallelism between the blade and table travel.

c. If any deviation in parallelism occurs, slightly loosen the keel lock knob on the deviation side, and slightly

tap the keel to complete the adjustment of the parallelism.

Fig. 4

Quick angle position stop

There are four quick angle position stops below the dial which are used to locate the common angles

quickly. Loosen the position stop lock screws by a hex wrench, the position blocks can be slid to desired

angles, then tighten the lock screws. When the position blocks are not needed, flip them down.

Position Stop Lock Screws

Acrylic Cursor

Quick Angle Position Stops x 4

Hex Countersunk Head Screw

Middle of Keel

Front Keel Lock Knob

Содержание JMPv2 Jointmaker Pro

Страница 1: ......

Страница 3: ...1 English Version...

Страница 17: ...15 8 Exploded View and Parts List...

Страница 19: ...17...

Страница 22: ...20 2 1 1 3 2 1 2 2 2 M5x80 M5 1 2 3 4 5 A x2 6 x1 7 x1 1 2 5 4 3...

Страница 23: ...21 4 5 4 1 3 3 1 25mm 3 3 1 2 1 2 3 4 2 3 3 1 25mm 1 2 3...

Страница 24: ...22 4 3 4 1 2 a 8 b c 4 4 4 4 5 1 2 3 5 4...

Страница 25: ...23 4 5 6 4 6 6 1 2 3 6...

Страница 27: ...25 5 7 8 1 7 90 2 90 3 90 1 2 3 90 90 4 8 5 1 5 7 8 1 2 3...

Страница 28: ...26 6 1 9 1 2 3 4 5 6 7 8 9 10 9 2 4 4...

Страница 29: ...27 7 1 2 3 4 5 6 7 1 5 2 2 3 3 4 5 4 5 4 4 6 7 5 4 2 4 4 4 4 4 1...

Страница 30: ...28 8...

Страница 32: ......