12

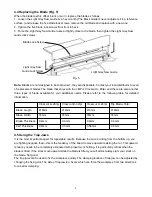

5. Calibrating the Perpendicularity and Parallelism (Fig.7&8)

The Jointmaker Pro has been calibrated in factory, however, to ensure the cutting accuracy which may be

influenced during transportation, please calibrate as follows:

Note:

Before sliding the table, the trap/straight fence must be removed to avoid the fence being cut by

blade without calibration.

1. Adjust the blade angle until the blade is perpendicular to table at position

①

in Fig. 7, tighten the front

and rear keel lock knob.

2. Inspect the angles at position

②③

by using a square:

If the angles at position

②③

are all 90°, enter Step 3;

If any angle deviation occurs at position

②

or

③

, loosen the rear keel lock knob, grasp the rear part of keel

and slightly swing it to make the blade be perpendicular to table.

●

Repeat Step 1 and 2 until the blade at position

①②③

is perpendicular to the table.

3. With the blade perpendicular to the table, inspect that if the indicator points to 90°. If not, loosen the

indicator lock screw, slightly adjust the indicator to 90° and tighten the screw.

●

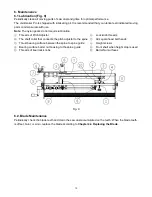

With the front and rear keel lock knobs tightened, the parallelism calibration should be based on the

premise that the blade has been perpendicular to the table.(The parallelism calibration takes the front end

of keel as a standard )

4.Position a hex key wrench (or a hard card) against the fence. Lightly touch the end of the wrench to the

leading edge of the saw blade (as illustrated in Fig. 8). Slide the table slowly to inspect the parallelism

between the blade and table travel.

5. If any deviation in parallelism occurs, slightly loosen the rear keel lock knob, two rear keel adjustable

screws and one of the two front keel adjustable screws, then hold the rear trunion tightly by hand and

slightly tap the keel to complete the adjustment of the parallelism.

(Depending on different using habits, the parallelism calibration also can be done by taking the rear end of

keel as a standard.)

●

Repeat Step1 to 5 until that the perpendicularity and parallelism are well calibrated.

Tip:

Calibration is essential for achieving high quality precision cutting performance, please be patient to

complete the calibration steps before formal cutting operations.

Fig.7

Fig. 8

Rear Keel Lock Knob

Square

Keel

1

2

3

Indicator Lock Screw

Indicator

Front Keel Lock Knob

Table Travel

Front Plate

Rear Keel Lock Knob

Rear Keel Adj. Screws

Front Keel Lock Knob

Fence Lock Plate

Front Keel Adj. Screws

Rear Plate

Front Trunion

Rear Trunion

Содержание JMPv2 Jointmaker Pro

Страница 1: ......

Страница 3: ...1 English Version...

Страница 17: ...15 8 Exploded View and Parts List...

Страница 19: ...17...

Страница 22: ...20 2 1 1 3 2 1 2 2 2 M5x80 M5 1 2 3 4 5 A x2 6 x1 7 x1 1 2 5 4 3...

Страница 23: ...21 4 5 4 1 3 3 1 25mm 3 3 1 2 1 2 3 4 2 3 3 1 25mm 1 2 3...

Страница 24: ...22 4 3 4 1 2 a 8 b c 4 4 4 4 5 1 2 3 5 4...

Страница 25: ...23 4 5 6 4 6 6 1 2 3 6...

Страница 27: ...25 5 7 8 1 7 90 2 90 3 90 1 2 3 90 90 4 8 5 1 5 7 8 1 2 3...

Страница 28: ...26 6 1 9 1 2 3 4 5 6 7 8 9 10 9 2 4 4...

Страница 29: ...27 7 1 2 3 4 5 6 7 1 5 2 2 3 3 4 5 4 5 4 4 6 7 5 4 2 4 4 4 4 4 1...

Страница 30: ...28 8...

Страница 32: ......