Page 44

Maintenance and Lubrication Schedule

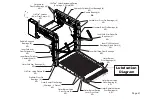

Inner fold arm cam followers (4)

Parallel arm pivot pin bearings (16)

Handrail pivot pin bearings (4)

Hydraulic cylinder pivot bushings (8)

Inspect Lift-Tite

™

latch rollers for wear or damage,

positive securement and proper operation (2)

Inspect inner roll stop for:

• Wear or damage

• Proper operation. Roll stop should just rest on

top surface of the threshold plate.

• Positive securement (both ends)

Inspect handrail components for wear or damage,

and for proper operation

Inspect microswitches for securement and proper

adjustment.

Make sure lift operates smoothly

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Apply Light Oil - See Lubrication Diagram

Correct, replace damaged parts and/or relubri-

cate.

Resecure, replace or correct as needed. See

Platform Angle Instructions and Tower Micro-

switch Adjustment Instructions.

Replace damaged parts.

Resecure, replace or adjust as needed. See

Microswitch Adjustment Instructions.

Realign towers and vertical arms. Lubricate or

correct as needed.

1500

Cycles

continued

continued