Page 40

Maintenance and Lubrication

All listed inspection, lubrication and maintenance

procedures should be repeated at 750 cycle

intervals following the scheduled 4500 cycle

maintenance procedures. These intervals are

a general guideline for scheduling maintenance

procedures and will vary according to lift use and

conditions. Lifts exposed to severe conditions

(weather, environment, contamination, heavy

usage, etc.) may require inspection and mainte-

nance procedures to be performed more often

than speci

fi

ed.

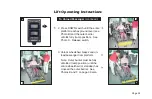

Cycle Counter:

NCL-2 Series lift models are

equipped with a cycle counter located on the top

of the pump module. This cycle counter allows

the lift attendant/operator to easily track the

number of cycles during daily inspections of the

lift.

Discontinue lift use immediately if maintenance

and lubrication procedures are not properly per-

formed, or if there is any sign of wear, damage or

improper operation. Contact your sales represen-

tative or call The Braun Corporation at 1-800-THE

LIFT

®

. One of our national Product Support repre-

sentatives will direct you to an authorized service

technician who will inspect your lift.

Speci

fi

ed (recommended)

Available

Braun

Lubricant Type Lubricant

Amount

Part

No.

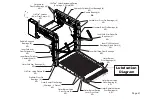

See the Maintenance/Lubrication Schedule for recommended applications per number of cycles.

LO - Light Oil

DE - Door-Ease

Light Grease

Lubriplate

14 oz.

(Multipurpose) Can

LG - Light Grease

15807

15806

15805

Light Penetrating Oil

LPS2, General Purpose

16 oz.

(30 weight or equivalent)

Penetrating Oil

Aerosol Can

Stainless Stick

Door-Ease

1.68 oz.

Style (tube)

Stick (tube)