Field experience, supported by engineering endurance tests, indicates the use of the proper gear oil and a pro-

gram of regular preventive maintenance will help provide extended gear train life and reliable hoist brake perform-

ance. For this reason, BRADEN has published the following specifications to assist in determining which lubricant

is best suited to your application.

For simplicity, BRADEN has listed available products in each temperature range that have been tested and found

to meet our specifications. This is not to say that other lubricant brands would not perform equally as well.

If the following lubricant brands are not available in your area, make certain your lubricant vendor supplies you with

oil that is equivalent to those products listed below.

RECOMMENDED PLANETARY GEAR OIL

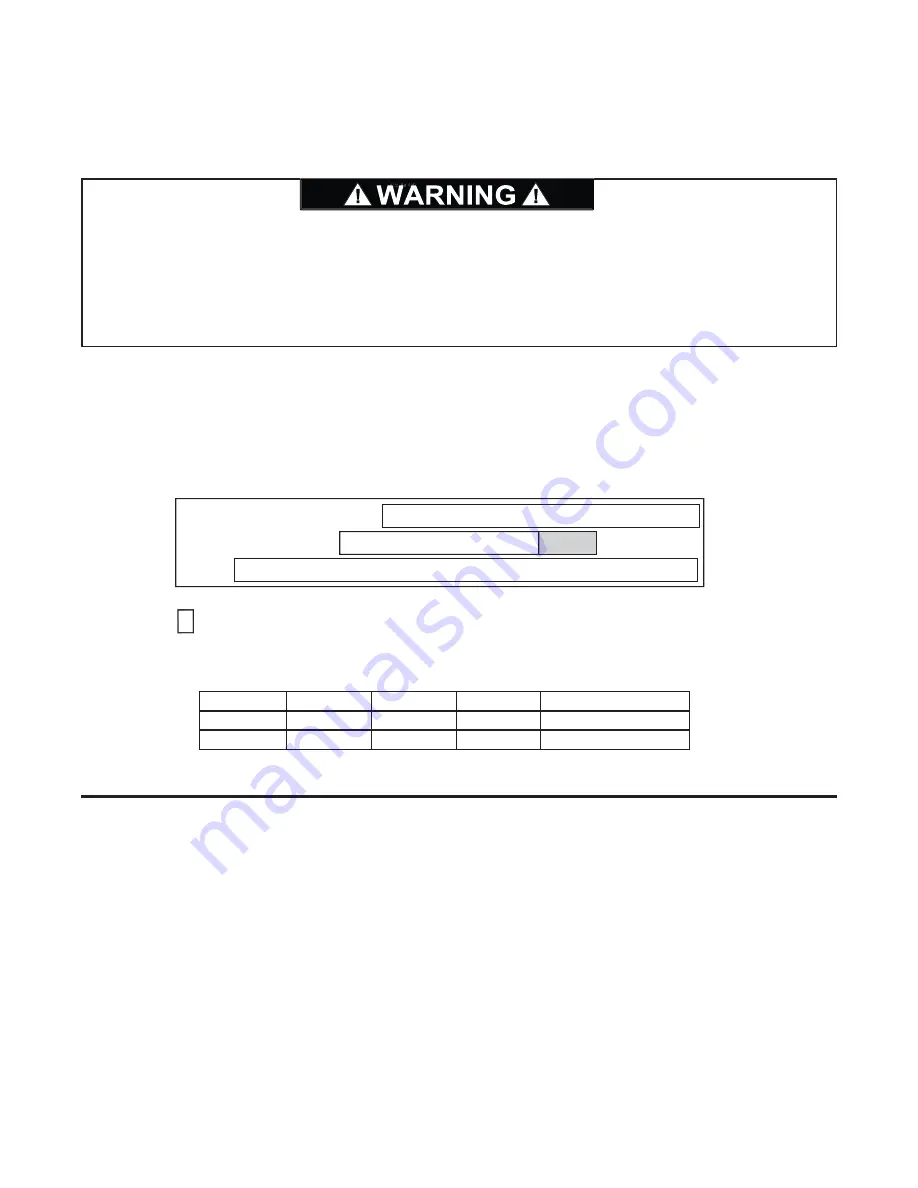

Failure to use the proper type and viscosity of planetary gear oil may contribute to intermittent brake clutch slip-

page which could result in property damage, severe personal injury or death. Some gear lubricants contain large

amounts of EP (extreme pressure) and anti-friction additives which may contribute to brake clutch slippage or

damage to brake friction discs or seals. Oil viscosity with regard to ambient temperature is also critical to reli-

able brake clutch operation. Our tests indicate that excessively heavy or thick gear oil may contribute to inter-

mittent brake clutch slippage. Make certain that the gear oil viscosity used in your hoist is correct for your pre-

vailing ambient temperature.

PREVAILING AMBIENT TEMPERATURE

o

F -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

o

F

EXXON SPARTAN EP220 OR EQUIVALENT

AGMA 5 EP, ISO VG 220

EXXON SPARTAN EP150 OR EQUIVALENT

AGMA 4 EP, ISO VG 150

MOBILGEAR SHC 150 or 220

SYNTHETIC OR EQUIVALENT

o

C -40 -30 -20 -10 0 10 20

30 40 50

o

C

NOTE:

SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS: OFFSHORE

CRANES, SUSTAINED FAST DUTY CYCLES OR FREQUENT LIFTING.

Texaco Meropa 150, previously used as factory fill, may no longer be widely available due to current market conditions. As of

mid-year 2002, planetary hoists are factory filled with Exxon Spartan EP150, or equivalent. The chart below relates the Texaco

products to 4 currently available oils. Consult your oil supplier for other equivalent oils if required.

i

Texaco

Mobil

Exxon

Shell

Meropa 150

Meropa 220

Mobilgear 629

Spartan EP 150

Omala 150

Mobilgear 630

Spartan EP 220

Omala 220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

9/2002

PREVAILING AMBIENT TEMPERATURE

o

F -40 -30 -20 -10 0 10 20 30 40 50 60 70 80 90 100 110 120 130

o

F

EXXON SPARTAN EP220 OR EQUIVALENT

AGMA 5 EP, ISO VG 220

EXXON SPARTAN EP150 OR EQUIVALENT

AGMA 4 EP, ISO VG 150

SYNTHETIC OR EQUIVALENT

o

C -40 -30 -20 -10 0 10 20

30 40 50

o

C

NOTE:

SHADED TEMPERATURE RANGE IN THE CHART ABOVE NOT RECOMMENDED FOR SEVERE APPLICATIONS SUCH AS: OFFSHORE

CRANES, SUSTAINED FAST DUTY CYCLES OR FREQUENT LIFTING.

Texaco Meropa 150, previously used as factory fill, may no longer be widely available due to current market conditions. As of

mid-year 2002, planetary hoists are factory filled with Exxon Spartan EP150, or equivalent. The chart below relates the Texaco

products to 4 currently available oils. Consult your oil supplier for other equivalent oils if required.

i

Texaco

Mobil

Exxon

Shell

Meropa 150

Meropa 220

Mobilgear 629

Spartan EP 150

Omala 150

Mobilgear 630

Spartan EP 220

Omala 220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

Texaco

Mobil

Exxon

Shell

Meropa 150

Meropa 220

Mobilgear 629

Spartan EP 150

Omala 150

Mobilgear 630

Spartan EP 220

Omala 220

Chevron

Gear Compounds EP 150

Gear Compounds EP 220

9/2002

16

Crane inspection records, as well as records of preventive maintenance, repairs and modifications to the hoist(s)

should be available and accessible for a minimum of two (2) years. These records should include, but not be lim-

ited to, hoist model and serial number, name and employer of repair / inspection technician, date and description

of preventive maintenance, functional test reports and repairs.

To provide our customers with the highest qualified outlets for hoist service and repair, BRADEN has established

Braden Authorized Service Centers. These Authorized Service Centers are equipped with factory-trained service

personnel, up-to-date service information, extensive parts inventories and complete testing facilities, and are audit-

ed by BRADEN on a regular basis for compliance.

BRADEN strongly recommends the use of BRADEN

Authorized Service Centers

for maintenance, repair and inspection of BRADEN planetary hoists. Consult the

BRADEN Technical Service Department at (918)-251-8511 for the name of your nearest BRADEN Authorized

Service Center.

INSPECTION RECORDS & RETENTION