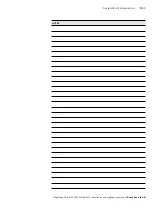

Troubleshooting

73/80

Hägglunds DOb, RE 15327-WA/05.2017, Installation and maintenance manual,

Bosch Rexroth AB

Causes Of Trouble And Its Effect In The Hydraulic Installation

Pressure Valves

Flow Control Valves

Directional Control

Valves

Fluid

output Drive

(motor)

others

1.Valve chatter due

to dirt on valve seal

2.Insufficient

damping (unsuitable

flow)

3.Flow noises when

operating

4.Unsuitable

characteristic curve

5.Wrong design

1.The valve

oscillates and

excites other control

elements into

oscillation

2.Flow noises

3.Control system

oscillating

1.Valve chatters due

to defective solenoid

or the voltage is too

low

2.Valve defective

due to dirt or wear

3.Flow through valve

is excessive

4.Pilot pressure

variations

5.On valves with

adjustable damping

the adjustment has

not been performed

6.Check the

electrical controls

1.Cavitation

problems due to

low fluid level or

viscosity too high.

(fluid temperature is

too low)

2.Fluid is

contaminated

and dirty leading

to damage and

blockage of

equipment

3.Fluid foams

1.Wear of running

surfaces

2.Control system

oscillating

1.Operating

pressure set too low

2.Internal leakage

due to wear

3.Dirty or damaged

valve seat

4.Broken spring

5.Unsuitable type.

(setting too low)

1.Pressure losses

excessive

2.False setting

3.Valve defective

4.Unsuitable type

1.Wrong switched

position (eg

pressureless)

2.Solenoid defective

3.Internal leakage

due to wear

4.Excessive fluid

velocity

5.Spool jams

1.Viscosity too low,

causing excessive

leakage.

2.Viscosity too high

causing excessive

flow resistance

3.Fluid foams.

1.Internal Leakage

2.Wear or running

surfaces

3.Excessive internal

friction causing low

efficiency

1.In the case of

pressure controls

there is a defect in

the open (or closed)

loop control circuit

2.Display

instruments are

defective

1.Valve chatter due

to dirt on valve seat

or valve worn

2.Insufficient

damping (unsuitable

type)

3.Excessive length

of undamped

remote control line

4.Unsuitable remote-

control valve

1.Valve dirty

2.Pressure losses

excessive

1.Valve chatters due

to defective solenoid

or the voltage is too

low

2.Valve defective

due to dirt or wear

3.Flow through valve

is excessive

4.Pilot pressure

variations

5. Adjustable

damping on valves,

has not been set

6.Check the

electrical controls.

1.Hydraulic fluid

dirty

2.Hydraulic fluid

foams.

1.Stick-slip effect

due to friction

2.Operation

below minimum

recommended

motor speed.

1.Insufficient load

counter-balance (eg

lowering control

valve)

1. Unsuitable fluid

for the duty.