English - 5

■

The dust that is produced while working can be

detrimental to health, inflammable or explo-

sive. Suitable safety measures are required.

Examples: Some dusts are regarded as carci-

nogenic. Use suitable dust /chip extraction and

wear a dust respirator.

■

Dust from light alloys can burn or explode. Al-

ways keep the workplace clean, as blends of

materials are particularly dangerous.

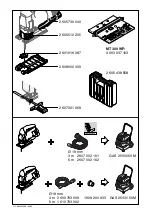

Vacuum Connection

The vacuum connection

6

is used to connect a

vacuum hose.

When inserting the vacuum connection

6

in the

base plate

7

, make sure that the plastic tip of the

vacuum connection engages in the correspond-

ing hole of the motor casing (see figure

).

To enable optimum dust extraction, use the splin-

ter guard

23

.

The machine can be plugged directly into the re-

ceptacle of a Bosch all-purpose vacuum cleaner

with remote starting control. The vacuum cleaner

starts automatically when the machine is

switched on.

The vacuum cleaner must be suitable for the ma-

terial to be worked.

When vacuuming dry dust that is especially detri-

mental to health or carcinogenic, use a special

vacuum cleaner.

For external dust extraction with a vacuum

cleaner, an extraction adapter must be used as

required (see accessories). Insert extraction

adapter and vacuum connection firmly.

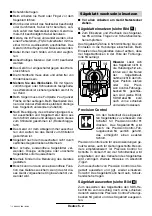

Cover Guard

The transparent cover guard

17

enables the col-

lection of chips and sawdust. To achieve opti-

mum results, it must always be mounted when

working with dust extraction. When working with-

out dust extraction, do not use the dust cover

17

.

Otherwise sawdust /wood chips can block the

view.

For tight curves it is best to use a narrow saw

blade.

When sawing metal or similar materials, apply

coolant/lubricant alongside the cutting line.

Straight Cuts in Thick Wood

– With the pushbutton for Precision Control

11

,

switch on the lateral guidance feature of the

saw blade.

– Use Bosch saw blades labelled “Precision for

Wood”.

– Adjust the exact cutting angle with use of a

commercial angle gauge

20

.

– Operate the machine with low feed only; the

orbital action and the stroke ensure sufficient

operational progress.

– Always guide the machine firmly against the

parallel guide

24

or an auxiliary guide rail and

avoid lateral pressure against the handle in or-

der to prevent the machine from jamming.

Circle Cutter/Parallel Guide

(Accessory

–

see figures

–

)

With the combined circle cutter /parallel guide

24

,

circular cutouts or parallel cuts in materials of up

to 30 mm thickness can be made.

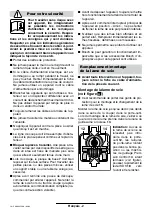

■

Before any work on the machine itself, pull the

mains plug.

■

For safe and proper working, always keep the

machine and the ventilation slots clean.

■

In order to avoid operational malfunctions, do

not saw gypsum board from below or over-

head.

In extreme working conditions, conduc-

tive dust can accumulate in the interior

of the machine when working with

metal. The protective insulation of the

machine can be degraded. The use of a

stationary extraction system is recom-

mended in such cases as well as fre-

quently blowing out the ventilation slots

and installing a residual current de-

vice (RCD).

The guide roller

13

should occasionally be

checked for wear and lubricated with a drop of oil.

If it is worn, it must be replaced.

If the machine should fail despite the care taken

in manufacturing and testing procedures, repair

should be carried out by an after-sales service

centre for Bosch power tools.

In all correspondence and spare parts orders,

please always include the 10-digit order number

given on the nameplate of the machine.

Dust/Chip Extraction

Tips

F

Maintenance and Cleaning

G

H

16 • 2 609 932 280 • 04.03

Содержание GST135BCE

Страница 2: ...2 2 609 932 280 04 03 ...

Страница 5: ...5 2 609 932 280 04 03 C 22 21 20 19 D 22 7 E 23 8 F G 24 H 24 ...