24

| English

2 610 956 206 | (15.1.08)

Bosch Power Tools

After longer periods of working at low speed, al-

low the machine to cool down by running it for

approx. 3 minutes at maximum speed with no

load.

Switching On and Off

Adjust the depth-of-cut before switching on or

off; see Section

“Adjusting the Depth-of-cut”

.

To

start

the machine, press the On/Off switch

19

and keep it depressed.

To lock the

pressed

On/Off switch

19

, press the

lock-on button

18

.

To

switch off

the machine, release the On/Off

switch

19

or when it is locked with the lock-on

button

18

, briefly press the On/Off switch

19

and then release it.

Constant Electronic Control

Constant electronic control holds the speed

constant at no-load and under load, and ensures

uniform working performance.

Adjusting the Depth-of-cut

f

The adjustment of the depth-of-cut may on-

ly be carried out when the router is

switched off.

For coarse adjustment of the depth-of-cut, pro-

ceed as follows:

– Place the machine with the router bit mount-

ed on the workpiece to be machined.

– Set the scale for fine adjustment

2

to

“0”

.

– Set the step buffer

8

to the lowest position;

the step buffer engages noticeably.

– Loosen the clamping lever for depth-of-cut

coarse adjustment

5

by turning in counter-

clockwise direction so that the depth stop

4

can move freely and faces against the step

buffer

8

.

– Push the release lever

16

downward and

slowly lower the plunge router until the rout-

er bit

22

touches the surface of the work-

piece. Let go of the release lever

16

again to

lock this plunging depth.

– Set the scale for coarse adjustment of the

depth-of-cut

6

to

“0”

.

– Adjust the required depth-of-cut by turning

the adjustment knob for coarse adjustment

7

and reading the scale

6

. Pay attention not to

readjust the rotatable scale

6

.

– Lock the clamping lever for depth-of-cut

coarse adjustment

5

by turning in clockwise

direction and slide the router upward.

For deep cuts, it is recommended to carry out

several cuts, each with little material removal.

By using the step buffer

8

, the cutting process

can be divided into several steps. For this, ad-

just the desired depth-of-cut with the lowest

step of the step buffer and select the higher

steps first for the initial cuts. The clearance of

the steps can be changed by screwing the ad-

justing screws

further in or out.

After a trial cut, the depth-of-cut can be set ex-

actly to the desired measure by turning the ad-

justment knob

1

; turn in clockwise direction to

increase the cutting depth and in anticlockwise

direction to decrease the cutting depth. The

scale

2

can be used for guidance. One full turn

corresponds with a setting range of 2.0 mm; a

graduation mark on the top edge of the scale

2

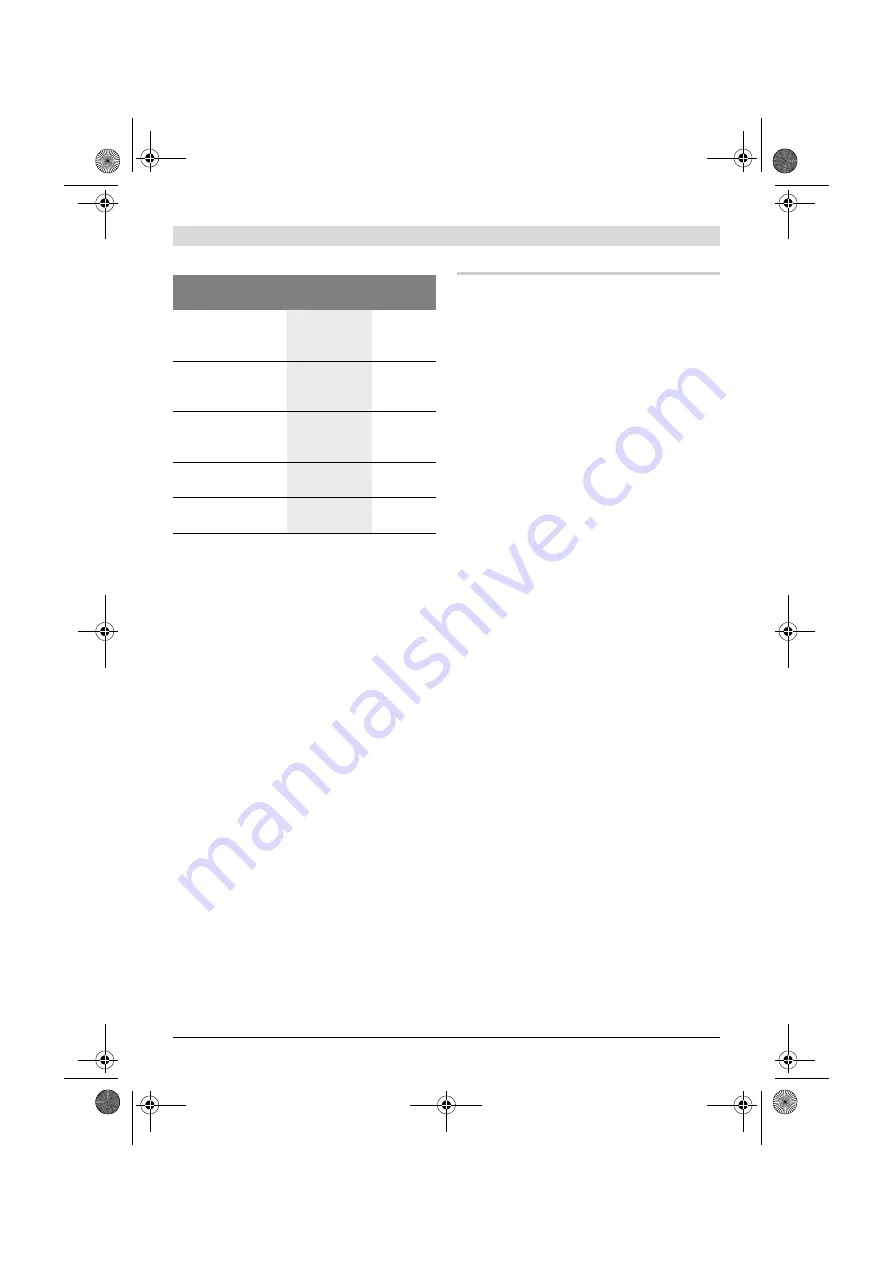

Material

Router bit di-

ameter (mm)

Thumb-

wheel 17

Hardwood (Beech)

4

– 10

12

– 20

22

– 40

5

– 6

3

– 4

1

– 2

Softwood (Pine)

4

– 10

12

– 20

22

– 40

5

– 6

3

– 6

1

– 3

Particle Board

4

– 10

12

– 20

22

– 40

3

– 6

2

– 4

1

– 3

Plastics

4

– 15

16

– 40

2

– 3

1

– 2

Aluminium

4

– 15

16

– 40

1

– 2

1

OBJ_BUCH-622-001.book Page 24 Tuesday, January 15, 2008 5:10 PM