Applications Manual FHP560 Controller

| 5

Bosch Thermotechnology Corp.

Data subject to change

Page____ of ____

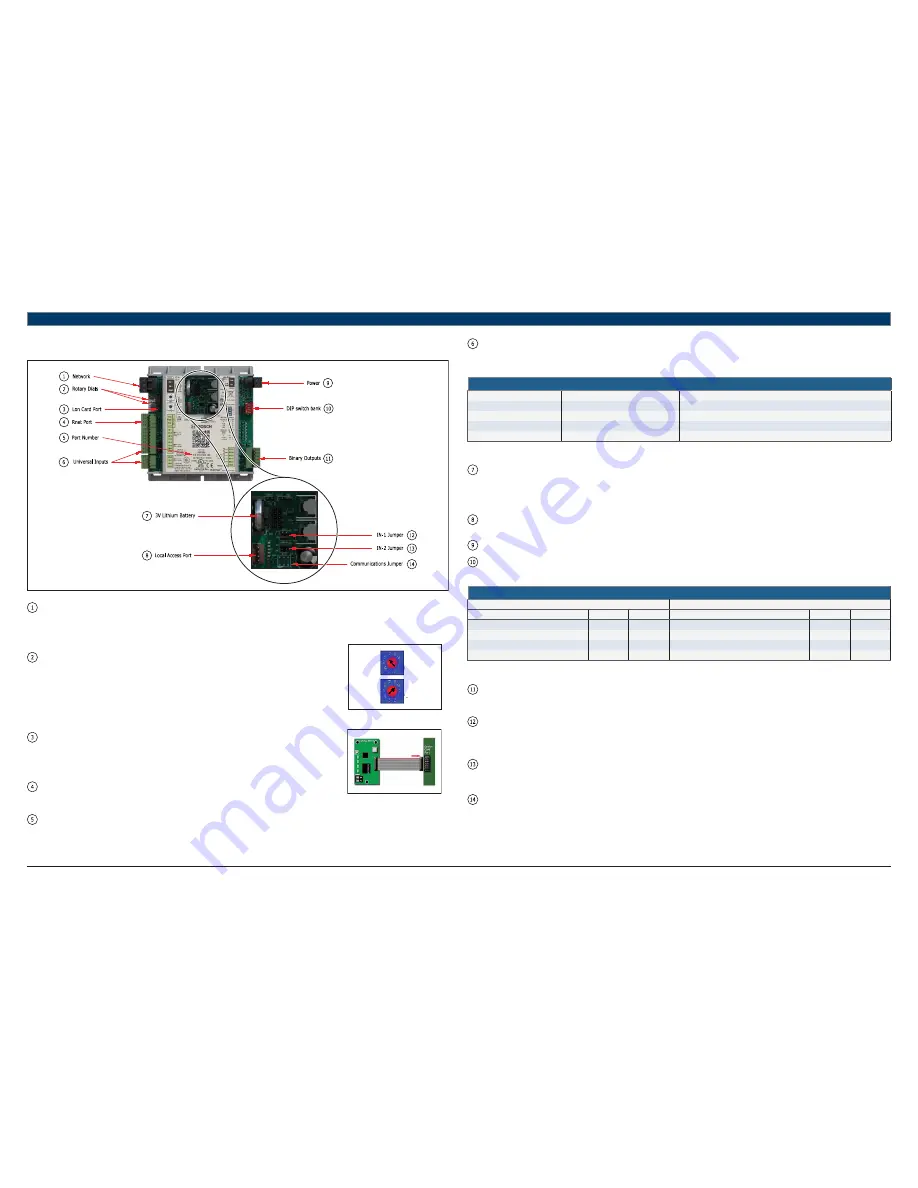

5 Controller Components & Features

Fig. 3 FHP560 Components

Network:

This block represents the communications port on the FHP560. The comm port can be con

fi

gured to communicate in two ways

(RS-485 or BACnet over ARC156) using the Communications Jumper. The communications wiring should be landed at the Net+, Net-,

and Shield terminals, ensuring the same polarity is maintained throughout the network segment. The “BAS Port Settings” DIP switch

is used to set the baud rate for the network, using the same baud rate for all controllers on the network. The LEDs (Rx and Tx)

fl

ash

repeatedly when the controller is communicating with the network.

Rotary Dials

: The rotary dials are used to address the FHP560 so it can be uniquely identi

fi

ed over a network.

Ones

Te

n

s

The top dial represents the Tens digit while the bottom one represents the Ones digit, allowing

for hardware-based addressing of up to address 99. Before setting or changing the address

make sure the FHP560 is powered off; the controller only reads the address when the module

is turned on. In the example shown in Fig. 4, the rotary dial is set to address 69.

Fig. 4 Rotary Dials

Lon Port:

For network integration applications involving the LonWorks network platform, the LON card

will be required to enable communication over this protocol. The card is ordered separately

and connects to the controller port as shown. Ensure that the communications jumper is in the

top position (EIA-485) and the BAS port settings are con

fi

gured using the DIP switch bank

(see DIP Switch).

Rnet Port:

The Rnet port is a four-connector block used mainly for wiring the ZS combo sensors to

the FHP560. It consists of 2 points for power (12VDC, Gnd) and 2 points for communication

(Rnet + and Rnet -). This port may also be used to hardwire a BACview6 module.

Fig. 5 Lon Connection

Part Number:

The FHP560 part number represents both the hardware and software components of the FHP560, and therefore changes if the

controller is ordered with a special software other than the standard (7.05.03) version.

Inputs:

There are 6 universal inputs on the FHP560. All inputs are capable of accepting thermistor (analog), pulse or dry contact (binary)

signals, but the

fi

rst 2 inputs (IN-1 and IN-2) are also capable of reading 0-5VDC signals; use the corresponding jumpers to select

between Therm/dry and 0-5V for these inputs. Refer to the “Ports Assignment and Overview” page for further details on con

fi

guring

these inputs.

Inputs

Input

Signal Type Supported

Description

IN-1 and IN-2

0-5Vdc

Input impedance of the FHP560 is approx. 30-kOhm

All

Thermistor

Precon type 2 (10-kOhm @ 77°F/25°C)

All

Dry Contact

3.3Vdc wetting voltage detects contact position

All

Pulse

Pulse counting up to 10 pulses per second.

Table 2

Battery:

The 10-year Lithium CR2032 3V battery retains data (e.g. control programs, modi

fi

ed parameters, schedules, etc) for a

maximum of 10,000 hours during power outages. If the FHP560 experiences RAM loss (e.g. due to low voltage on the controller

or high voltage on the network), it may be reset by recycling the battery power. This operation should be performed with the

FHP560 powered off (no 24Vac power), and resolves most of all “bad controller” issues. All previously saved parameters are

retained upon power up.

Local Access:

The local access port is available for system start-up, servicing and troubleshooting using a BACview Interface (handheld or

virtual) or Field Assistant.

Power:

Input power for the FHP560. 24Vac +/-10%, 50-60Hz; 20VA power consumption, Single Class 2 source only, 100VA or less.

DIP Switch:

The BAS Port Settings DIP switch bank is used to set the appropriate network con

fi

guration when the FHP560 is integrated into

a Building Automation System (BAS). The following table details the different settings available (this information is also on the

FHP560 label):

Available Settings

BAUD RATE SETTING

PROTOCOL

SW1

SW2

SW3

SW4

9.6kbps

Off

Off

BACnet® MS/TP

Off

Off

19.2kbps

Off

On

N2

On

Off

38.4kbps

On

Off

Modbus

Off

On

76.8kbps

On

On

Option Card (LON)

On

On

Table 3

Outputs:

The FHP560 has

fi

ve (5) binary outputs that can each be connected to a maximum of 24Vac/26Vdc. Each output is a dry contact

(Form A) rated at 1A, 24V max. Refer to the “Ports Assignment and Overview” page for further details on con

fi

guring these

outputs.

IN-1 Jumper:

This two-position jumper is used to set the input type selection for IN-1 as follows:

—

Top position is labeled W4 and configures IN-1 for dry/therm signals

—

Bottom position is labeled W5 and configures IN-1 for 0-5V signals

The jumper is default to the bottom position (W5) for 0-5V from factory.

IN-2 Jumper:

This two-position jumper is used to set the input type selection for IN-2 as follows:

—

Top position is labeled W6 and configures IN-2 for dry/therm signals

—

Bottom position is labeled W7 and configures IN-2 for 0-5V signals

The jumper is default to the top position (W6) for Dry/Therm from factory.

Com Jumper:

This two-position jumper is used to con

fi

gure the network communication mode for the FHP560 as follows:

—

Top position is labeled EIA-485 and configures the FHP560 for RS-485 communications for BACnet MS/TP, N2, ModBus, or

Lon.

—

Bottom position is labeled BACnet over ARC156 and configures the FHP560 for BACnet over ARC156 at 156kbps. This

selection is a unique implementation of the industry standard ARCNET protocol and the jumper should only be set to this

position if employing that protocol.

The jumper is default to the top position (EIA-485) from factory.