18 EP Series

Subject to change without prior notice Revised 12-13

8733922168

Dehumidificationselector (Figure #9, item [11]) should

be selected to ‘YES’.

2) Units without optional Hot Gas Reheat, on

dehumidification call, the heat pump fan will operate at a

lower speed to increase dehumidification while cooling.

Dehumidification selector ((Figure #9, item [11]) should

be selected to ‘NO’.

Caution

In this mode, the heat pump will only dehumidify the

space when it is running in cooling mode.

Dehumidification indicator LED (Figure #9, item [4]) will

energize when dehumidification call is present.

To the left of the red and green status LED’s is a row of

1/4” male quick connects. These are used to pass

thermostat inputs on to the rest of the control circuit.

Remember to always turn off unit power at the circuit

breaker before attaching or disconnecting any wiring

from these connections to avoid accidental short circuits

that can damage unit control components.

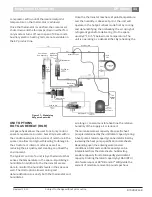

Y1

Y1

POWER

TO PUMP

C

2 DP/ST

RELAYS

POWER SUPPLY

UNIT

TERMINAL

STRIP

(24VAC)

C

FLUID DIFFERENTIAL PRESSURE SWITCH

(DPS)

Pressure/temperature ports are recommended in

both the supply and return lines for system flow

balancing. The water flow can be accurately set by

measuring the water-to-refrigerant heat exchangers

water side pressure drop. See the unit specification

sheets for the water flow and pressure drop

information in the back of this manual.

The discharge water from the heat pump is not

contaminated in any manner and can be disposed of

in various ways depending on local codes (i.e.

discharge well, dry well, storm sewer, drain field,

stream, pond, etc.

When using a single water well to supply both

domestic water and the heat pump care must be taken to

insure that the well can provide sufficient flow for both.

In well water applications a slow closing solenoid valve

must be used to prevent water hammer.

Solenoid valves should be connected across Y and C

on the interface board for all. Make sure that the VA

draw of the valve does not exceed the contact rating

of the thermostat. The function of the differential

switch is to prevent or stop compressor operation

should the water supply fail. This will prevent the unit

from locking out on a safety, requiring a manual reset

to restart.

The switch is piped between the water entering and

leaving connections. Should the pressure drop fall

below set value the switch will open de-energizing the

DPS relay thereby stopping the compressor.

The controller has an adjustment to change the

minimum pressure differential required to open the

switch and may require field adjustment.

The blower operation will not be affected by this

option.

Caution

The start-up process should include checking the

operation of the switch when installed. This

should be done after the system is balanced.

Adjustment should be made if necessary.

Содержание EP015

Страница 1: ...EP Series Installation and Maintenance Manual 8733922168 Revised 12 13 ...

Страница 33: ...33 EP Series 8733922168 Revised 12 13 Subject to change without prior notice Electric Heat Wiring Diagram ...

Страница 34: ...34 EP Series Subject to change without prior notice Revised 12 13 8733922168 Electric Heat Wiring Diagram ...

Страница 38: ...38 EP Series Subject to change without prior notice Revised 12 13 8733922168 ...

Страница 39: ...39 EP Series 8733922168 Revised 12 13 Subject to change without prior notice ...