16 EP Series

Subject to change without prior notice Revised 12-13

8733922168

Electric Heat

HEAT RECOVERY PACKAGE

The Heat Recovery package is a factory mounted

option. It consists of a forced pumped unit that

employs a circulating pump to move water

through a double wall/vented heat exchanger and

returns the heated water to the water tank. The

water is heated by superheated refrigerant

discharge gas from the compressor. This waste

heat of the cooling mode captured by the heat

recovery increases the capacity and efficiency of

the heat pump unit. If the air temperature is

uncomfortable coming from the air vents in the

heating mode the heat recovery may need to be

turned off. In the heating mode the heat recovery

captures heat that would normally be used for

space heating.

Caution

If heat recovery unit is installed in an area where

freezing may occur, the unit must be drained

during winter months to prevent heat exchanger

damage. Heat exchanger ruptures that occur

due to freezing will void both the heat recovery

package warranty and the heat pump warranty.

HOT GAS BYPASS

The function of the hot gas bypass valve is to

prevent icing of the air coil when the unit is

operating at low load conditions. This situation

could arise if the space experiences widely varying

loads, for example a conference center. Without a

hot gas bypass circuit the evaporating temperature

will fall and ice could form on the coil restricting air

flow and aggravating the situation. Eventually the

coil could be totally blocked resulting in possible

refrigerant liquid entering the compressor and

failure of the system

The hot gas bypass valve is located in the discharge

line from the compressor and diverts hot gas to the

inlet of the air coil. The valve is factory set to open

when the evaporating pressure falls to 75 PSI for an

R-410A system and will modulate to prevent the

pressure falling any lower. This setting is field

adjustable and this set point may be adjusted as

required.

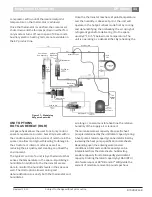

ECM INTERFACE BOARD- CONSTANT

AIRFLOW MOTOR (OPTION)

In addition to providing a connecting point for

thermostat wiring, the interface board also

translates thermostat inputs into control com-

mands for the Electronic Commutated Motor

(ECM) DC fan motor and provides thermostat

signlas to unit’s UPM board. The thermostat

connections and their functions are as follows:

Figure #9

[1] Motor harness plug

[2] Blower CFM adjustment

[3] Motor settings

[4] Dehumidification indication

[5] Thermostat digital contact inputs

[6] CFM count indicator

[7] Thermostat input status indication

[8] Reheat digital outputs

[9] Thermostat outputs

[10] 24 VAC

[11] Dehumidification method selector

Caution

CFM LED is an approximation. Utilize conventional

Test and Balance equipment for accurate airflow

measurement.

Содержание EP015

Страница 1: ...EP Series Installation and Maintenance Manual 8733922168 Revised 12 13 ...

Страница 33: ...33 EP Series 8733922168 Revised 12 13 Subject to change without prior notice Electric Heat Wiring Diagram ...

Страница 34: ...34 EP Series Subject to change without prior notice Revised 12 13 8733922168 Electric Heat Wiring Diagram ...

Страница 38: ...38 EP Series Subject to change without prior notice Revised 12 13 8733922168 ...

Страница 39: ...39 EP Series 8733922168 Revised 12 13 Subject to change without prior notice ...