15

EP Series

8733922168

Revised 12-13 Subject to change without prior notice

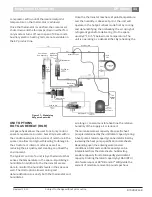

Well Water System

On FHP units’ gas flow to Hot Gas Coils is made

with the increase of DC volts output from Duct

Stat.

8. Check actuator location pin for movement

during modulation. If there is no movement of

pin and the actuator is moving, locate set-screw

and tighten motor body on actuator shaft.

a) To tighten, unscrew set-screw so that it is

loose (use a 3mm metric Allan wrench),

ensure that shaft is all the way to the CCW

position (use a wrench if necessary)

b) Locate clutch release knob (top left of Motor body)

Press knob down, while holding down, rotate turn

knob to full CCW position. Tighten set-screw.

Note:

When the pin is to the right, hot gas

flows to the right (Hot Gas Coil) and if to the

left, hot gas flows to the left (Condenser Coil).

c) An outdoor air low limit switch can be

placed between Transformer and R of the

terminal block to keep the Compressors

from running below 65 degrees entering

outdoor temperature.

d) The factory provided-field installed discharge

air temperature sensor installed by the

contractor in the units discharge air plenum

controls the position of the modulating hot

gas reheat valves to maintain a desired

constant discharge air temperature. This

sensor should be installed at least 10 feet

from the units discharge air outlet to ensure

proper mixing of the leaving air.

e) In situations of low fluid temperature the

amount of hot gas could be limited and the

design leaving air temperature may not be

attained. This can be remedied by the use of

field supplied head pressure controlled

water regulating valves or manually adjusting

the water flow rates accordingly.

Depending on the application in the unoccupied

mode the unit should be disabled through some

type of relay or time clock and the outside air

damper be closed. This will ensure that raw or

unconditioned outside air is not introduced into the

building during the unoccupied mode.

Caution

Control of the hot gas modulation is by the

thermostat in the supply air duct or through the

building management system. A separate

controller is used to control the unit itself.

ELECTRIC HEAT

Internally mounted supplemental electric heat

is available on select models of the EP series.

Electric heating elements can operate along

with reverse cycle heating as auxiliary heat or

in lieu of reverse cycle heating (refrigeration

heating) as emergency backup heat.

Availability matrix, including available nominal

kW capacities is shown below:

Caution

Internal Eectric Heat cannot be provided with hot

gas reheat. Units with internal Electric Heat must

have 2 field power supplies.

Table 2: Electric Heater Compatibility

tor Only)

Units

5kW

10 kW

15

kW

20

kW

EP018

ü

x

x

x

EP024

ü

ü

x

x

EP030

ü

ü

x

x

EP036

ü

ü

ü

x

EP042

ü

ü

ü

x

EP048

ü

ü

ü

ü

EP060

ü

ü

ü

ü

EP070

ü

ü

ü

ü

Caution

Internal mounted Electric Heat is only available on

top blow vertical cabinets, end blow horizontal

cabinet.

Содержание EP015

Страница 1: ...EP Series Installation and Maintenance Manual 8733922168 Revised 12 13 ...

Страница 33: ...33 EP Series 8733922168 Revised 12 13 Subject to change without prior notice Electric Heat Wiring Diagram ...

Страница 34: ...34 EP Series Subject to change without prior notice Revised 12 13 8733922168 Electric Heat Wiring Diagram ...

Страница 38: ...38 EP Series Subject to change without prior notice Revised 12 13 8733922168 ...

Страница 39: ...39 EP Series 8733922168 Revised 12 13 Subject to change without prior notice ...