14 EP Series

Subject to change without prior notice Revised 12-13

8733922168

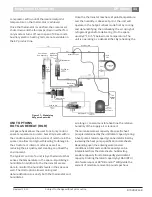

Refrigerant Flow Path

Low Temperature Well Water

When low temperature well water is utilized as the

water source (below 55°F), a means of establishing

two flow rates, one for the cooling/reheat mode

and one for heating mode is recommended. In the

cooling mode at low entering water temperatures

and standard flow rates discharge pressures and

corresponding discharge gas temperatures are

relatively low. At these conditions when the reheat

mode is initiated the low temperature discharge

gas can reduce reheat capacity. A means to reduce

the water flow rate and elevate the discharge

pressure/ temperature in cooling/reheat mode

should be provided. Conversely, at low entering

water temperatures in the heating mode system

suction pressure is reduced causing a loss in

heating capacity. A means of providing higher flow

in the heating mode should be provided. The

simplest way to accomplish the above is to install

water regulating valves.

Indoor Pool Dehumidifying During

Winter Months

It is important to remember that when in the reheat

mode the heat pump is cooling and reheating. A

secondary means of heating the space during the

dehumidification mode should be provided. The

indoor space temperature should be kept at least

2°F above the pool water temperature. If this is not

done the warm pool water attempts to heat the

space and the humidity levels increase

exponentially. The heat pump is normally sized to

handle the design latent load moisture removal. A

second heat pump or resistance heat should be

provided to handle the structural loss load.

Caution

A protective coating is highly recommended for all

pool applications due to the highly corrosive

chemical environment.

Operating Pressures and Temperatures

Operating pressures and temperatures in the

reheat mode vary slightly from standard cooling

mode operating characteristics. The variations are

as follows:

Discharge Pressure: (-) 5 to 20 PSIG

Discharge Gas Temperature: (-) 5°F to 15°F

Suction Pressure: (+) 5 to 10 PSIG

Suction Gas Temperature: (+) 5°F to 10°F

Sequence of Operation - Modulating Hot

Gas Reheat (MHGRH)

Modulating Hot Gas Reheat differs from On/Off in

that the reheat function is always active. The

purpose of MHGRH is to deliver air at or close to

neutral conditions.

FHP modulating hot-gas reheat uses a modulating hot

gas valve that is controlled by a duct thermostat and

temperature sensor. This modulates the hot gas flow to

the reheat coil raising the temperature of the air and

maintaining the preset temperature of the supply air.

The thermostat sends a DC signal of 0 – 10 volts to

the motorized valve which, depending on the

supply air temperature, will open or close to main-

tain the preset temperature setting.

System Set Up:

1. Determine piping arrangement of re-heat valve.

Refer to Figure 7, hot gas enters the center port

and may leave through the right or left ports

depending on stage of operation.

2. With power off, install the duct sensor.

3. Install the thermostat at a location that can be

easily accessed.

4. Wire the thermostat, sensor and unit as shown

in the wiring diagram supplied.

5. See the Typical Wiring Diagram for volts dial and

dip switch settings for thermostat.

6. With all connections made, turn power on and

observe Hot Gas Valve actuator movement.

7. Set the thermostat to its highest or lowest value

and observe Hot Gas Valve actuator movement.

Содержание EP015

Страница 1: ...EP Series Installation and Maintenance Manual 8733922168 Revised 12 13 ...

Страница 33: ...33 EP Series 8733922168 Revised 12 13 Subject to change without prior notice Electric Heat Wiring Diagram ...

Страница 34: ...34 EP Series Subject to change without prior notice Revised 12 13 8733922168 Electric Heat Wiring Diagram ...

Страница 38: ...38 EP Series Subject to change without prior notice Revised 12 13 8733922168 ...

Страница 39: ...39 EP Series 8733922168 Revised 12 13 Subject to change without prior notice ...