6720818454 (2016/02) US

SSB

24 | Installation

•

Remodeling areas;

•

Garages with workshops.

4 .7 .1

General venting and combustion air piping system

The SSB boilers require an approved vent system-designed for positive

pressure.

Vent connectors serving appliances vented by natural draft shall not be

connected to any portion of mechanical draft systems operating under

positive pressure.

Ensure that the flue pipes and seals are not damaged.

Use only primer and glue compounds approved for use with the vent

material used.

Never install a barometric or a thermally controlled vent damper with this boiler.

Do not route the flue system piping through or inside another duct that is

used for exhausting air or other flue gases.

The condensate trap must be primed at all times. Failure to do so may

allow combustion gases to escape into boiler room.

The unit is to be used for either direct vent installation or for installation

using room air for combustion. When room air is used, it is necessary to

provide an adequate opening for the fresh air intake.

You must use any of the vent/air piping methods shown in this manual.

Be sure to locate the unit such that the vent and combustion air piping

can be routed through the building and properly terminated.

The boiler / vent installation must be in accordance with Venting

of Appliances, of the latest edition of the National Fuel Gas Code,

ANSI Z223.1/NFPA 54 or section, Venting Systems and Air Supply

for Appliances, of the CAN/CSA B149.1, Natural Gas and Propane

Installation code or applicable provisions of the local, state and federal

building codes.

All vent pipes must be installed according to the vent manufacturer’s

instructions.

The exhaust vent and the combustion air inlet lines must be supported to

prevent sagging per the vent manufacturer’s instructions.

Do not mix components from different systems. The vent system could

fail, causing leakage of flue products into the living space. Use only

approved materials.

Use of cellular core PVC and CPVC for venting system is not allowed.

a

a

WARNING: Improper venting due to failure to comply with

the warnings above can result in excessive levels of carbon

monoxide!

The exhaust pipe must be pitched a minimum of a 1/4 inch per foot back

to the boiler (to allow drainage of condensate).

The vent system shall be installed so as to prevent the accumulation of

condensate.

Consult local and state codes pertaining to special building code and fire

department requirements. Adhere to national code requirements.

Observe the listed maximum lengths of vent system, which are boiler

model dependent

To avoid moisture and frost build-up and to maintain clearances to openings

on adjacent structures, 45 ° and 90 ° elbows or tees may be attached to

the end of the vent termination pipe to direct exhaust plumes away from

the adjacent structure. The total allowable vent length, maximum number of

elbows and distance to air intake restrictions must be adhered to.

Due to the high efficiency of the unit it may discharge what looks like

white smoke especially when the outside air temperature is cold. This

is due to the presence of water vapor, normally present in the exhaust

gases.

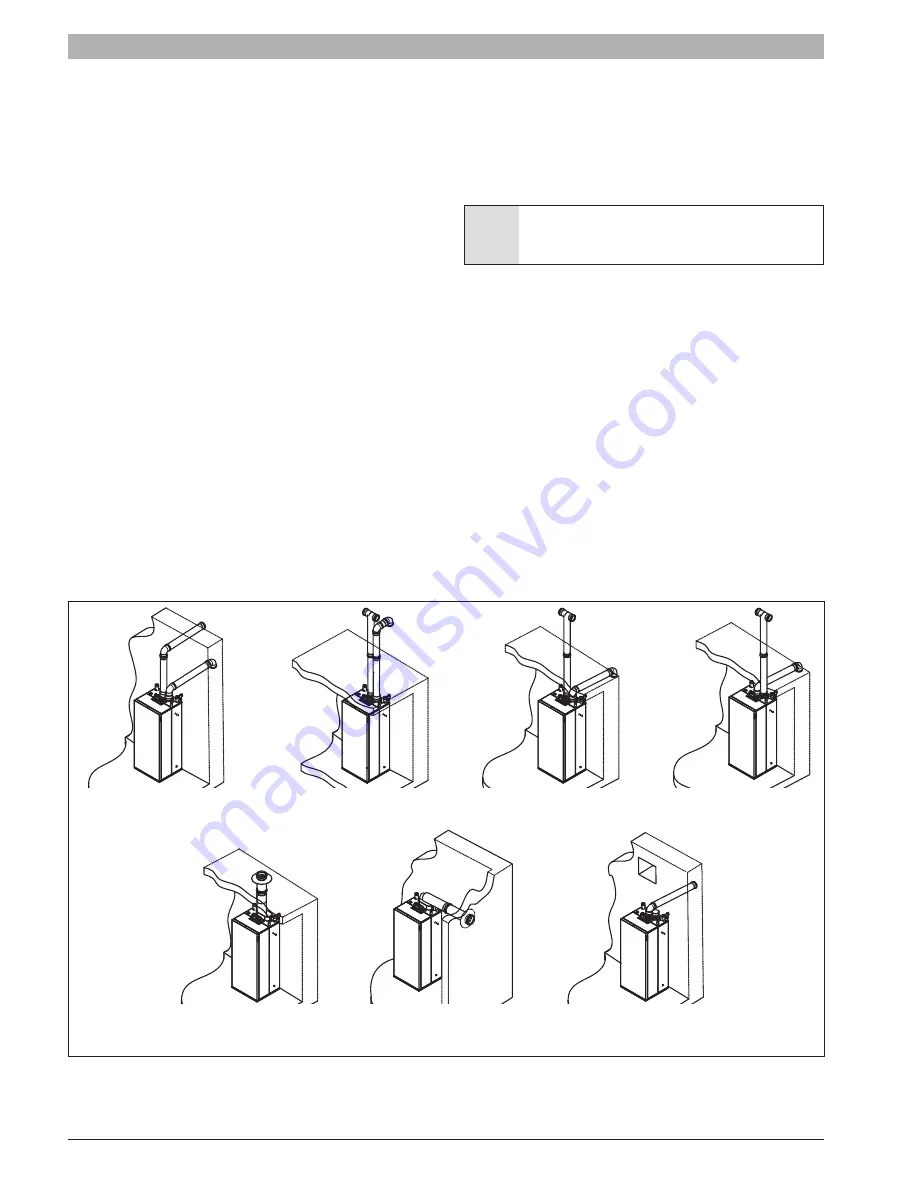

The following figure shows the acceptable piping installation for venting

and combustion air.

Fig. 25

Two pipes side wall

(Direct venting)

Two pipes vertical

(Direct venting)

Air intake side wall,

vent vertical

(Direct venting)

Air intake vertical,

vent side wall

(Direct venting)

Concentring

vertical pipe

(Direct venting)

Concentring side

wall pipe

(Direct venting)

One pipe venting

side wall (or vertical)

(Not direct venting)

Содержание Buderus SSB255

Страница 66: ...6720818454 2016 02 US SSB 66 Spare parts Notes ...

Страница 67: ...SSB 6720818454 2016 02 US Spare parts 67 Notes ...