6 720 644 942

Installation instructions

9

3.4

Combustion air requirements

The Protankless water heater holds cold water in its

copper heat exchanger and water valve when not in use.

Because of this, any cold air that comes down through

the unit's vent pipe is capable of freezing these

components. This Installation Manual specifies the

minimum vertical vent pipe and the amount of

combustion air required for this unit. When all

requirements are followed, the unit will operate properly

and safely. However, there may still be a risk of freezing

due to negative draft if all the combustion appliances in

the structure are not being supplied with sufficient

combustion air. A wood stove or furnace can pull it's

combustion air from the Protankless vent pipe. This

allows the cold infiltrating air to potentially freeze the

cold water in the AquaStar heater. Damage from

freezing is not covered under the manufacturer's

warranty. Supplying more combustion air for all

combustion appliances is the solution. Follow the

instructions on venting and checking adequacy of

combustion air. A HVAC specialist should be consulted

to design solutions for providing more make-up air if

necessary. Observe the following instructions

concerning combustion air.

Appliances located in unconfined spaces:

a)

An unconfined space is one whose volume is greater

than 50 cubic feet per 1000 Btu per hour of the

combined rating of all appliances installed in the space.

That would be 5850 cubic feet for the Protankless 520

HN alone.

b)

Installations in structures that have been tightly

constructed (air infiltration rate of 0.40 ACH or less)

must be provided with combustion air per the National

Fuel Gas Code. Consult a HVAC specialist if your air

infiltration rate is questionable.

Appliances located in confined spaces:

The confined space must be provided with two

permanent openings, one commencing within 12

inches of the top and one commencing within 12 inches

of the bottom of the enclosure. Each opening must have

a minimum free area of one square inch per:

• 1000 Btu/hr if all air is taken from inside the building.

• 2000 Btu/hr if all air is taken from the outside by

horizontal ducts.

• 4000 Btu/hr if all air is taken from the outside by

direct openings or vertical ducts.

Or the confined space must be provided with one

permanent opening or duct that is within 12 inches of

the ceiling of the enclosure. This opening must have a

minimum free area of one square inch per:

• 3000 Btu/hr if all air is taken from the outside by a

direct opening or vertical duct.

Louvers, grills and screens have a blocking effect. If the

effective free area is not known, increase the sizes of

your openings by 400% if your louvers are wood and by

135% if your louvers are metal. Refer to the National

Fuel Gas Code for complete information. In buildings of

tight construction all air should be taken from outside.

3.5

Mounting Heater

The 520 HN is approved for installation on a combusti-

ble wall provided the floor covering below the heater is

noncombustible. For installations in an alcove or closet,

maintain the minimum clearances to combustible and

non-combustible materials listed in Fig. 4.

Remove cover and inspect.

B

Remove the flow control and power adjustment

knobs.

B

Unsrew the cover fixing screws, see Fig. 10.

B

Loosen the two Phillips head screws located on

bottom rear of cover. Remove cover by pulling it

outward and then lifting upwards.

B

Ensure that the flue terminal is clear.

B

After inspection, replace front cover and tighten

screws.

Install incandescent particle tray.

B

Install incandenscent particle tray using screws

provided as shown in Fig. 9.

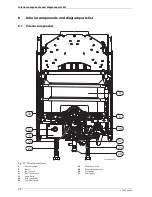

Fig. 9

Incandescent particle tray illustration

Warning:

before starting installation:

B

check that there are no loose parts

inside the appliance

B

ensure that gas pipe, gas valve, and

burner have no damage and are

properly fitted.

B

Read chapter 2.2 to verify proper gas

type and to verify all parts are included

in box.

i

Front cover must be removed in order to

inspect

components

visually

(see

instructions below).

Incandescent particle tray

Screws