Operating Instructions 1-8DEC 230V

Troubleshooting

10.1 Continued

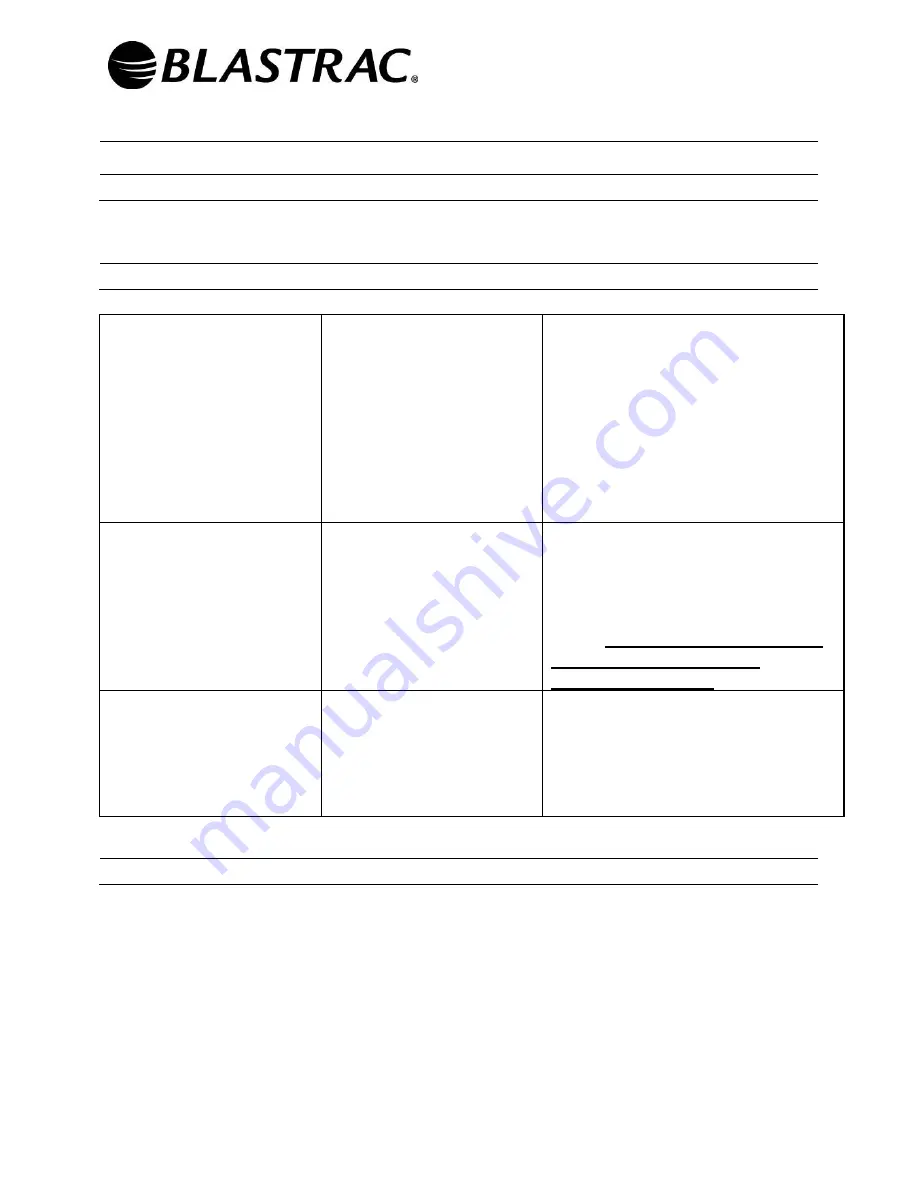

Abrasive leakage.

Improper sealing.

Feed spout

Improper control cage

setting.

Abrasive valve setting

Check all seals for wear.

Check feed spout alignment and

rubber seal.

Abrasive rebounding from side of

machine. Check blast pattern.

Be sure abrasive valve closes

when handle is released. Readjust

if necessary.

Machine hang-up.

Uneven work surface/

floor obstruction.

Pull up on steering handle to raise

machine to clear small obstructions

or uneven work surfaces. Shut

abrasive valve if obstruction cannot

be cleared. Pull back machine to

clear.

Use caution when raising

seal due to high velocity

abrasive exposure.

Loss of cleaning action.

Machine travel speed too

fast.

Abrasive contaminated.

Slow travel speed.

Clean storage hopper and replace

abrasive. Check ventilation

system.

10.2 Troubleshooting

– Ventilation System (Dust Collector)

Note: Once the Dust Collector has been in operation for several minutes, a stable

operating level will result. Sudden changes in operation can usually be traced to a

malfunction.

43

Содержание 1-8DECMKI

Страница 8: ...Operating Instructions 1 8DEC 230V Operator Responsibilities Section 2 2 1 Operator Responsibilities 7...

Страница 18: ...17...

Страница 19: ...18...

Страница 20: ...19...

Страница 29: ...Operating Instructions 1 8DEC 230V Edging Mode Section 6 6 1 Edging Mode 28...

Страница 31: ...30...

Страница 32: ...Operating Instructions 1 8DEC 230V Equipment Calibration Section 7 7 1 Equipment Calibration 31...

Страница 35: ...Operating Instructions 1 8DEC 230V Wear Parts Section 8 8 1 Wear Parts 8 2 Maintenance Log 34...

Страница 38: ...Operating Instructions 1 8DEC 230V Blast Wheel Replacement Section 9 9 1 Blast Wheel Replacement 37...

Страница 50: ...Operating Instructions 1 8DEC 230V Specifications Section 12 12 1 Specifications 49...