5

GENERAL SAFETY INSTRUCTIONS

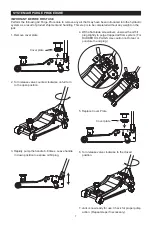

Position the jack

Position the jack to only lift the areas of the vehicle as specified by the vehicle manufacturer.

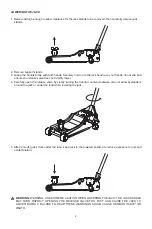

Always use jack stands

After lifting the vehicle, always support the load with appropriately rated vehicle jacks stands before working

on the vehicle.

Do not overload jack

Do not overload this jack beyond its rated capacity. Overloading this jack beyond its rated capacity can cause

damage to or failure of the jack.

Always use on hard level surfaces

This jack is designed only for use on hard level surfaces capable of sustaining the load.

Chock and block (stabilize)

Apply parking brake in vehicle before operating jack.

A chock is a wedge for steadying an object and holding it motionless, or for preventing the movement of a

wheel. Chock the wheel opposite the end being lifted.

When you block a load, you secure and support a load that is being lifted. The block(s) or stabilizer(s) should

have a weight capacity that is greater than the weight of the load which is being lifted.

Centre load on jack saddle

Centre load on jack saddle before lifting vehicle.

Off-centre loads and loads lifted when the jack is not level can cause loss of load or damage to the jack.

Do not raise or lower the vehicle unless tools, materials and people are clear.

When the lift is being lowered, make sure everyone is standing at least 1.8 m (6 ft) away. Be sure there are no

tools or equipment left under or around the jack before lowering.

Always lower the jack slowly.

DO NOT USE THE JACK TO SUPPORT OR STABILIZE A LOAD.

Using the jack to support or stabilize a load may result in unexpected movement and result in serious injury,

being crushed and death. Always securely chock and block (stabilize) the load to be lifted. Never place any

part of the body under a raised load without properly chocking and supporting the load.

Never use the jack on curved or tubular vehicle

Bumpers will result in the vehicle slipping off the jack and falling, causing serious injury or death. Use a

bumper lift to lift most vehicles with curved bumpers or plastic bumpers.

Wear ANSI-approved safety glasses and heavy-duty work gloves during use.

Do not adjust the safety valve.

Do not move or dolly vehicle while jack is in use.

Stay alert. Use caution and common sense when operating jack.

Do not use a jack when tired,

incoherent, dizzy, under the use or drugs or alcohol.

Training

Read this manual before use. Do not allow anyone who has not read this manual, and/or does not understand

the requirements, to use the jack.

Spectators

Do not allow bystanders around the jack or under the load supported only by the jack. Do not allow anyone in

the vehicle while the jack is in use. Keep all bystanders away from vehicle when in use.

Inspection

Inspect the jack carefully before each use. Ensure the jack is not damaged, excessively worn, or missing

parts. -Do not use the jack unless it is properly lubricated. Using a jack that is not in good clean working

condition or properly lubricated may cause serious injury.

Additional notes:

Save the receipt, warranty and these instructions.

Do not modify the jack in any way.

Unauthorized modification may impair the function and/or safety and

could affect the life of the equipment. There are specific applications for which the jack was designed.

Always check for damaged or worn out parts before using the jack.

Broken parts will affect the

equipment operation. Replace or repair damaged or worn parts immediately.

When jack is not in use, store it in a secure place out of the reach of children. Inspect it for good working

condition prior to storage and before re-use.

Содержание T830018ZH

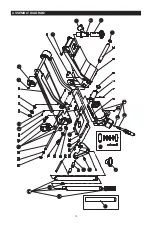

Страница 13: ...13 ASSEMBLY DIAGRAM...

Страница 29: ...29 SCH MA DE MONTAGE...