10

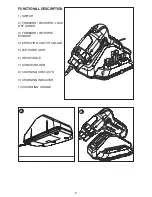

• Place desired screw onto screw holder carrier (

figure G

). Ensure screw threads rest on

screw carrier as shown.

• Slide screw holder arm back towards screwdriver bit. Ensure screwdriver bit tip and

screw head are fully engaged. (

figure H

)

• At this time the screw is being held securely to the screw holder carrier by means of an

internal magnet.

Note:

Magnet will not work on non-ferrous screws.

• Ensure unit is set for driving screws in the forward position.

• While driving the screw, the screw holder carrier and arm will retract allowing the screw

head to be driven to its desired depth (

figure I

).

• After use, return screw holder arm back into its storage position to protect screw holder

from damage.

Screw driving Notes:

• Do not use double ended screwdriver bits.

• Do not use screwdriver as a pry bar in any position.

• To avoid screwdriver being turned on accidentally, do not carry in your pocket.

led lIGHt

A light (5) is built-in to the screwdriver above the spindle (6). To use the light without the

spindle turning, place the forward / reverse selector (2) in the neutral position.

dRIllING

• Insert the appropriate hex shank drill bit.

• Select the largest screw icon on the clutch collar for maximum torque.

• Select forward rotation.

Note:

When drilling, the bit may become disconnected from the spindle upon

withdrawing it from the material. Should this occur, the bit can be removed by re-inserting

the hex shank into the spindle and running the tool in the reverse direction.

GeNeRAl dRIllING tIPS

• This tool is not recommended for drilling in masonry.

• Use sharp drill bits only.

• Drill bits for metal can be used for drilling holes in wood. These bits must be sharp and

should be pulled out frequently when drilling to clear chips from the flutes.

• Support and secure work properly, as instructed in the safety Instructions.

• Use appropriate and required safety equipment, as instructed in the safety instructions.

• Secure and maintain work area, as instructed in the safety instructions.

• Apply pressure in a straight line with the bit. Use enough pressure to keep the bit biting

but not so much as to stall the motor or deflect the bit.

• Hold the tool firmly to control its twisting action.

• DO NOT CLICK THE TRIGGER OF A STALLED TOOL OFF AND ON IN AN ATTEMPT

TO START IT. DAMAGE TO THE TOOL CAN RESULT.

• Minimize stalling on breakthrough by reducing pressure and slowly drilling through last

part of hole.

• Keep the motor running while pulling the bit out of a drilled hole. This will help reduce

jamming.

• Make sure switch turns tool on and off.

WARNING:

It is important to support work properly and to hold the tool firmly to prevent

loss of control which could cause personal injury.

MAINteNANce

Use only mild soap and damp cloth to clean the tool. Never let any liquid get inside the

tool; never immerse any part of the tool into a liquid.

IMPoRtANt:

To assure product SAFETY and RELIABILITY, repairs, maintenance and

adjustment (other than those listed in this manual) should be performed by authorized

service centers or other qualified service personnel, always using identical replacement

parts.

Содержание Li4000

Страница 6: ...6 C D G H E F ...

Страница 33: ...33 ...

Страница 36: ...36 Cat No Li4000 Form 90609922 March 2014 Copyright 2014 Black Decker Printed in China ...