12

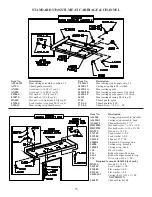

e. STATIONARY BAR ASSEMBLY:

Check condition of nylon filler (Item No. 177), change every four (4) weeks.

Check condition of saw guide (Item No. S119A), check tracking of blade through guide, back of blade should be

centered in hole, replace every six (6) months. Check condition of lower blade back-up guide (Item No. S608).

Check condition of back-up guide, should have

1

/

32

” gap between back of blade and saw guide carbide.

Replace every six (6) months.

f. SAW CLEANERS:

Check condition of blade cleaners, replace every four (4) weeks.

i. MEAT CARRIAGE ASSEMBLY:

Check free movement through full range of travel. Check side to side for

excessive clearance, adjust as necessary. Check condition of and grease bearings, replace as necessary. Check

condition of thumb guard, replace as necessary.

j. SAFETY ITEMS:

Safety end cut pusher plate is with machine and accessible. All warning labels are present,

properly affixed and legible. Model and Serial Number plate is properly affixed and legible. Wall poster within

operators view from machine. Manual accessible to operator.

g. RATCHET ASSEMBLY:

Check for smooth operation through full range of travel. Check condition of trigger

spring, replace as necessary.

h. SLIDE GIBS(Movable Head Only):

Check that head structure moves freely up and down. Check for side to side

and front to rear tolerance, adjust as required. Grease every four (4) weeks.

B. LUBRICATION:

1. UPPER WHEEL BEARINGS:

Grease every

four (4) months. Change grease every twelve (12)

months. (See instructions at right.)

2. LOWER BEARING HOUSING:

Grease

every four (4) months. Change grease every

twelve (12) months.

4. MEAT CARRIAGE BEARINGS:

Grease

every four (4) weeks.

5. SAW GUIDE BAR:

Oil daily with food

machine oil.

When lubricating the upper wheel bearing it is important that the

three hex head screws securing the upper wheel hub cap be

loosened slightly before attempting to pump grease into the grease

fitting. Loosening the screws allows for an escape of old broken

down grease and air from the bearing cavity. Failure to loosen the

screws before greasing the upper bearings can cause the upper shaft

seal to be dislodged from the upper wheel allowing grease to

escape and moisture to get into the cavity. When finished greasing

the bearings, retighten the three screws. Take care to also clean off

any grease that was pushed out of the cavity during greasing.

6. MOTOR BEARINGS:

Bearing grease will lose its lubricating ability over time, not suddenly. The lubricating

ability of a grease (over time) depends primarily on the type of grease, the size of the bearing, the speed at which

the bearing operates and the severity of the operating conditions. Good results can be obtained if the following

recommendations are used in your maintenance program.

A high grade ball or roller bearing grease should be used. Recommended grease for standard service conditions is

Polyrex EM (Exxon Mobil).

Equivalent and compatible greases include: Texaco Polystar, Rykon Premium #2, Pennzoil Pen 2 Lube, and

Chevron SRI.

Recommended lubrication intervals is every 12 months with the equivalent of two (2) teaspoons of grease.

If motor does not have zerk fittings, the motor bearings are sealed for life.

USE BIRO No. 374 GREASE FOR RE-GREASING

SEE INSTRUCTIONS BELOW

3. SLIDE GIBS:

Grease every four (4) weeks.

Содержание 3334SS-4003FH-TL

Страница 2: ......

Страница 12: ...9 OPERATOR S NOTES ...

Страница 24: ...21 COMMON TRUE LEFT PARTS ...

Страница 25: ...22 COMMON TRUE LEFT PARTS ...

Страница 32: ...29 ...

Страница 33: ...30 ...