11

MAINTENANCE

ALWAYS

Turn Off, Unplug From Power Source and Perform Lockout/Tag Out Procedure to This

Machine

BEFORE

Cleaning or Servicing.

NEVER

Touch This Machine Without Training and Authorization By Your Supervisor.

ALWAYS

Keep Hands Clear of Band Type Saw Blade and Other Moving Parts.

NEVER

Bypass, Alter, or Modify This Equipment in Any Way From It’s Original Condition

.

USE ONLY GENUINE BIRO

Parts and Accessories Properly Installed.

PROMPTLY REPLACE

Any Worn or Illegible Warning Labels.

SHARP MOVING BAND TYPE SAW BLADE

TO AVOID SERIOUS PERSONAL INJURY

1. Machine should be generally inspected every time it is cleaned (at least daily) to ensure that it is in good

condition and has not been damaged or tampered with.

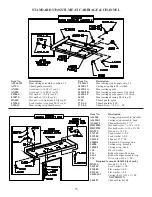

a. SAW WHEELS:

Clean outer diameter grooves daily. Check for cracks, gouges or wear on the flange and grooves.

A. GENERAL

DO NOT IMMERSE UPPER WHEEL ASSEMBLY IN WATER

b. WHEEL CLEANER ASSEMBLIES:

Check condition of fiber cleaner, change every four (4) weeks.

c. REMOVABLE FINGER LIFT ASSEMBLY:

Check condition of saw guard, make sure mounting bolts are tight

and the “DANGER EXPOSED BLADE” decal is affixed and legible. Check condition of upper saw guide (Item No.

S602B), replace every six (6) months. Check adjustment of upper saw guide. Should be

1

/

32

” between back of blade

and saw guide carbide.

NEVER USE THIS MACHINE WITHOUT PROPERLY INSTALLED

AND FUNCTIONING SAW GUIDE BAR AND SAW GUARD

1. Remove the finger lift fastener knob and the finger lift assembly.

2. Remove the finger lift fastener stud.

3. Push the saw guide bar up and out of the top of the head structure.

4. Remove the saw guide bar spring.

5. Clean and lubricate the babbitt pocket area (the square indented area that seats

the saw guide bar spring).

6. Lower the new saw guide bar spring through the top of the babbitt pocket area

and guide the spring into position with a standard screwdriver.

(NOTE: drawing)

7. While holding the saw guide bar spring in position, re-enter the saw guide bar

from the top compressing the saw guide bar spring slightly until the saw guide

bar slides past the spring.

8. Replace the finger lift fastener stud, the finger lift assembly and the finger lift

fastener knob.

9. Test by making several adjustments.

d. SAW GUIDE BAR: Check condition of saw guide bar, replace as necessary. Check saw guide bar spring or brass

pad used with saw guide bar lock knob for proper tensioning of bars. Either system should hold the bars in any

desired position in its travel. Replace saw guide bar spring (Item No. 193) or brass pad (Item No. 194) and lock

knob (Item No. 194KS-1) as necessary using the following instructions.

Содержание 3334SS-4003FH-TL

Страница 2: ......

Страница 12: ...9 OPERATOR S NOTES ...

Страница 24: ...21 COMMON TRUE LEFT PARTS ...

Страница 25: ...22 COMMON TRUE LEFT PARTS ...

Страница 32: ...29 ...

Страница 33: ...30 ...