Fig. 12

Fig. 13

Fig. 15

(Fig. 11-12)

ADJUSTING TABLE BEVEL

(Fig. 12)

ADJUSTING DEPTH GAUGE

(Fig. 13-15)

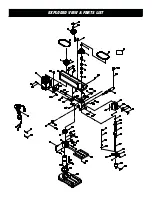

CHANGING SPEEDS

Drive belt

Motor pulley

Pivot nut

Pivot bolt

Tension bolt

Motor

Depth stop

locking collar

Depth gauge

14

ASSEMBLY & ADJUSTMENTS

3. Rotate the table adjustment handle counterclockwise to

lower the table.

4. Position the table to the desired height and retighten the

table lock handle.

The drill press is equipped with a tilting table that allows

you to drill angled holes. The table can be tilted left or right,

from 0º to 45º.

To tilt the table:

1. Loosen the large hex bolt located underneath the table.

2. Use the bevel scale to tilt the table to the desired angle.

3. Retighten the hex bolt securely.

Adjust the depth gauge when you need to drill a number of

holes to exactly the same depth.

1. Loosen the depth stop locking collar.

2. Rotate depth gauge to desired setting.

3. Retighten depth stop locking collar, if needed.

The spindle speed is determined by the location of the belt

on the pulleys inside the head assembly. The speed chart

located on the cover inside the head assembly shows the

recommended speed and pulley configuration for each

drilling operation.

NOTE

: The pivot bolts located on the side of the tool should

allow the motor to move freely once the tension bolt is

loosened.If the motor is difficult to move, it may be necessary

to loosen the pivot bolts slightly (1/4 turn). Do not retighten.

1. Lift head assembly cover from side to open.

2. Loosen the tension bolt until there is enough slack in the

belt for it to be repositioned around the pulleys.

3. Reposition the belt according to the speed chart.

Fig. 14

Spindle pulley

Содержание 10-INCH

Страница 23: ...EXPLODED VIEW PARTS LIST...