Operating manual for pneumatic grinding spindle

3

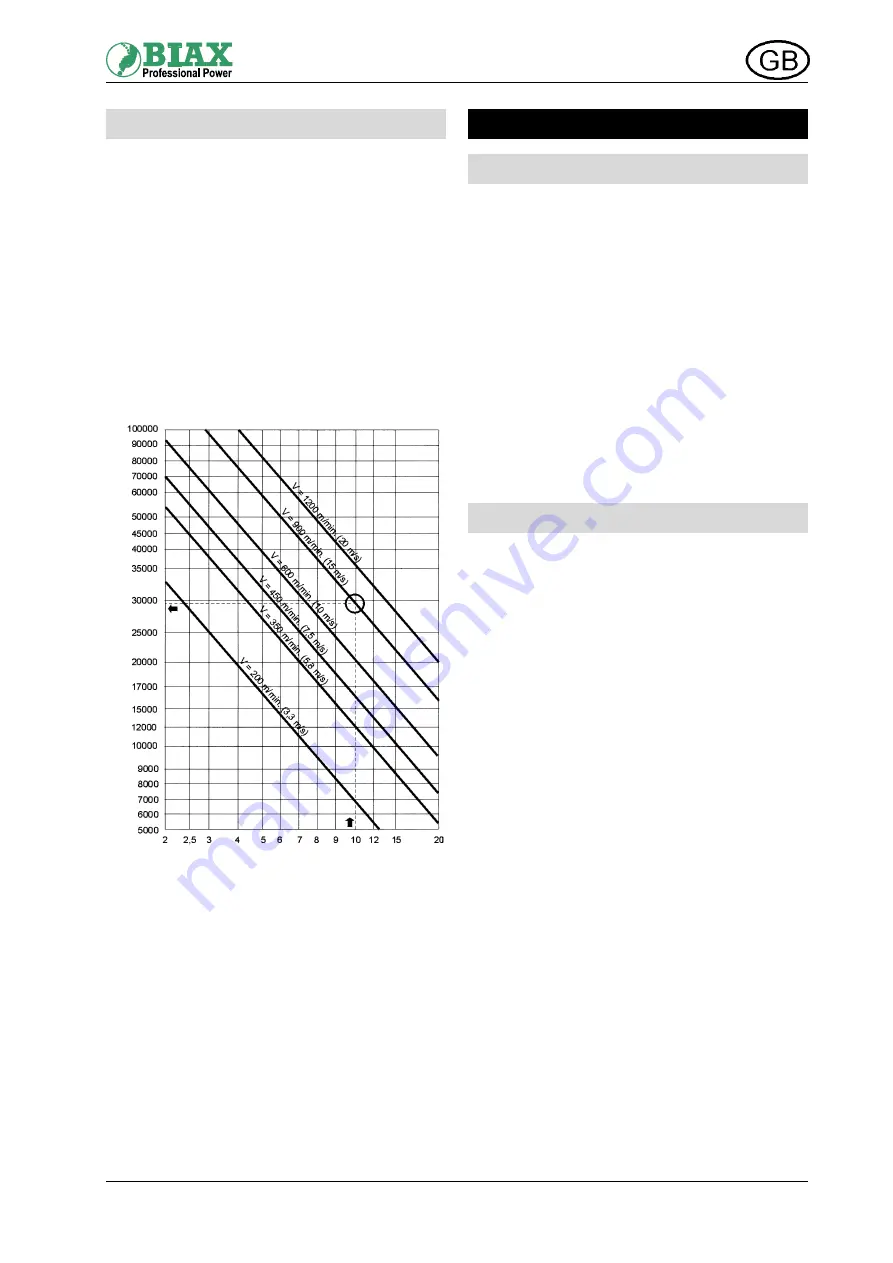

Speed selection

The processing speed is determined by the blade

diameter and the actual cutting speed (depending on

mounted tool). The relevant characteristics are shown in

the diagram Fig. 3.

To determine the machine speed, proceed as follows:

•

Select the respective blade diameter [mm] and draw

a vertical line to the point where it intersects with the

characteristic of the desired cutting speed [m/min].

•

Read the processing speed [rpm] on the axis to the

left by drawing a horizontal line from the intersection

with the characteristic.

Fig. 3: Speed selection

Example:

Determine the processing speed for hard-faced milling

spindles with a blade diameter of 10 mm; desired cutting

rate of v = 900 m/min.

Draw a vertical line from the blade diameter value 10 mm

to the intersection with characteristic v = 900 m/min

(marked in the diagram). From this point, draw a

horizontal line to the y-axis. The required processing

speed is approx. 28,600 rpm.

P

roc

essi

ng spee

d i

n

r

p

m

Blade diameter in mm

Maintenance

Maintenance unit

The air supplied by a compressed air system is generally

contaminated and contains a considerable amount of

moisture. Therefore, a maintenance unit must be installed

between the compressed air supply system and the

pneumatic tool.

The maintenance unit regulates the operating pressure

and filters and dries the air. The usability and service life

of your tools is thus considerably increased.

The usability and service life of your tools is thus

considerably increased.

For suitable maintenance units, please refer to our

catalogue. To ensure proper functioning of the BIAX

pneumatic grinding spindle, regularly inspect the

maintenance unit. Drain off any condensate and fill the

unit with BIAX special oil, if necessary.

Testing of idle speed

Check the idle speed of the grinder every 20 operating

hours, using a speed rev counter.

At an operating pressure of 6 bar, the nominal speed may

not be exceeded when operating the grinder without

grinding tool.