Installation

22

6.7

Fitting the flue system

Refer to the assembly instructions contained with-

in the chosen flue kit packaging for the correct as-

sembly and installation.

In general, it has to be taken in consideration that

the horizontal sections of the flue pipe must have

an horizontal sloping not less than 1.5 deg. (25

mm per metre) towards the boiler.

In the standard horizontal flue kit (Fig. 6.6A) the

flue pipe is angled within the air duct therefore the

air duct must be horizontally installed.

If one or more extensions have to be used they

must be adequately supported so that there is no

sag in the flue pipe and a minimum fall of 1,5 deg.

(25 mm per metre) over the whole length towards

the boiler is ensured.

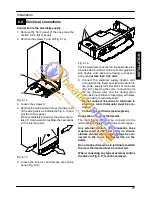

Before fitting the flue system, ensure that the flue

gasket shown in Fig. 6.5 (given with the boiler) is

fitted to the boiler.

Fig. 6.5

6.8

Choice of flue

The following flue kits are available for connecting

to the boiler:

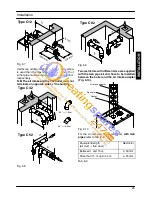

Standard horizontal flue kit (Fig. 6.6A)

Co---axial 60/100mm --- nominal length 1m

This kit is normally supplied with the boiler and can

be fitted to allow discharge to the rear or either

side of the boiler via the flanged boiler adapter

elbow. Minimum length required is 0.3 m. Maxi-

mum equivalent length of 2,7 metres can be

achieved utilising extensions. This flue system can

only be used to discharge horizontally, it is not de-

signed to enable termination in the vertical plane.

Vertical kit with 90

˚

elbow (Fig. 6.6B)

Co---axial 60/100 mm

Supplied with a straight flanged adapter a co---

axial elbow and a co---axial pipe with terminal, this

kit allows for a vertical rise of 0,5 m from the boiler.

In all circumstances the flue terminal must dis-

charge horizontally and the equivalent flue length

must not exceed 2,7 metres.

Elbows 45

˚

& 90

˚

(Fig. 6.6C)

Co---axial 60/100mm.

Elbow kits enable the standard flue kits to be offset

to overcome obstructions or ensure the correct

clearances for the flue terminal. Each elbow used

in addition to the standard flanged elbow reduces

the overall acceptable length of the flue system as

follows:

45

˚

reduce length by 0,5 m.

90

˚

reduce length by 1 m.

ø 60/100

ø 60/100

90

˚

=--- 1 m

45

˚

=--- 0,5 m

A

B

C

Min = 0,3 m

Max = 2,7 m

Type C12

Fig. 6.6

Twin pipe kits ø 80 mm (Fig. 6.7 --- Fig. 6.8 ---

Fig. 6.9)

Various twin (split) pipes kits and optional acces-

sories (elbows) are available to assist in the ter-

mination of the flue where the boiler is installed in

a location remote to an outside wall.

These kits allow for separation of the air supply

pipe from the pipe that discharges the exhaust

gasses. Consequently it is possible to extend the

flue system to a greater distance than that pro-

vided by the standard horizontal co---axial flue.

IN

S

TA

LLA

TI

O

N