11

MACHINE PREPARATION

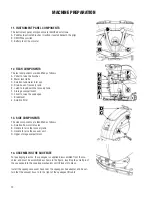

15. ADJUSTING THE SQUEEGEE HEIGHT

The height of the squeegee must be adjusted based on wear of the squeegee. To

do this, turn the knob (

2

) counter clockwise to raise the squeegee, and clock-

wise to lower it.

Note: the right and left wheels must be adjusted to the same level, so the

squeegee works parallel to the floo

r.

16. ADJUSTING THE SQUEEGEE INCLINATION

During working operation, the rear squeegee blade is slightly bent backwards

(by about 0.2 in (5 mm)) uniformly over its entire length. If it’s necessary to

increase the bend of the squeegee blade in the center, you must tilt the squeegee

backwards, rotating the adjuster (

1

) counter clockwise. To increase the bend of

the squeegee at the outside edges of the squeegee, rotate the adjuster clockwise.

After adjustment, tighten the jam nut.

17. RECOVERY TANK

Check the drain hose cap (on the rear of the machine) to ensure it’s closed.

Содержание E29941-00

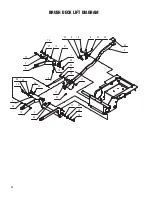

Страница 20: ...20 BRUSH DECK DIAGRAM 1 12 21 5 10 7 18 15 2 19 9 11 18 7 10 4 3 8 20 13 14 16 6 17 12 5 23 24 22 24 ...

Страница 36: ...36 SOLUTION CONTROL DIAGRAM 11 23 9 19 21 13 20 6 5 15 16 4 1 22 10 3 14 8 1 8 2 17 12 18 2 ...

Страница 40: ...40 ELECTRICAL COMPONENTS DIAGRAM 3 1 18 21 5 14 15 11 7 8 12 16 2 11 8 24 9 17 6 13 20 4 22 19 10 ...

Страница 42: ...42 ELECTRICAL DIAGRAM ...

Страница 51: ...51 ...