32

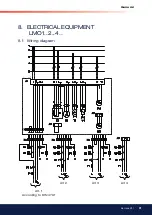

Bentone BF1

General

8.1.1 Component list

A1

Oil burner control

S3

Operations thermostat

E1

Preheater

S4

Temperature limiter

F1

Fuse, max 10 A

S7

Main switch

H1

Alarm lamp

T1

Ignition transformer

M1 Burner motor

Y1

Solenoid valve

P1

Timer (Accessory)

X3

Plug-in contact, burner

R1

Photocell QRB

X4

Plug-in contact, boiler

U2

UV-cell QRC

Preheater wiring colours:

A Blue

B Brown

C Black

The installation must be connected to the mains and fused according to local

regulations.

8.1.2 Function LMO1..2..4..

1a.

Operations switch ON, thermostat ON

The burner motor starts, ignition sparks initiated and pre-ventilation

continues until the set pre-ventilation period is over and the

solenoid valve (2) opens..

1b.

Operations switch ON, thermostat ON

The preheater is energized and the pre-heating period begins.

This continues until the operating temperature is reached and the

preheater thermostat closes. The burner motor starts, ignition

sparks initiated and pre-ventilation continues until the set pre-

ventilation period is over and the solenoid valve (2) opens.

2.

Solenoid valve opens

The oil mist is formed and ignited. The photocell indicates lame.

The ignition spark ceases 15 sec. after lame indication.

3.

a

b

Safety period runs out

If the lame is not present before the end of this period, the oil burner

control blocks further operation.

If the lame for any reason disappears after this time period, the

burner will make a new start attempt.

4-5

During operation

If burner operations are interrupted via the main switch or

thermostat, a new start will be initiated when conditions according

to point 1 are fulilled.

Oil burner control blocks

Red light on the oil burner control illuminates. The burner is re-

started by pressing the reset button.

Содержание BF1 RME

Страница 2: ......

Страница 11: ...11 Bentone BF1 General 2 11 12 1 10 5 15 24 22 21 23 13 3 17 14 19 20...

Страница 36: ...10 DECLARATION OF CONFORMITY...

Страница 38: ......

Страница 39: ......

Страница 40: ...Enertech AB P O Box 309 SE 341 26 Ljungby www bentone se www bentone com...