11

6.2

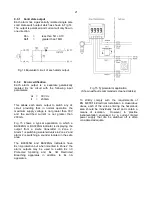

Indicator function:

FunC

This configuration function defines the relationship

between the indicator’s 4/20mA input current and

the indicator’s display. Three alternatives are

available:

5td

Standard linear relationship

root

Square root extraction

Lin

16 segment adjustable lineariser

To reveal the existing indicator function select

FunC

from the configuration menu and press

(

. If the

function is set as required, press

)

to return to

the menu, or press the

&

or

*

button to change

the setting, followed by the

)

button to return to

the configuration menu.

5td

Linear

Provides a linear relationship between

the 4/20mA indicator input current and

the indicator display.

root

Square root extraction

Primarily intended to linearise the square

law 4/20mA output from differential

flowmeters.

For reference, the following table shows

the output current from a non-linearised

differential flowmeter.

% of full flow

Current output mA

2.5

4.01

10.0

4.16

25.0

5.00

50.0

8.00

75.0

13.00

100.0

20.00

When the root function is selected the

indicator will display flow in linear units.

Lin

16 segment adjustable lineariser

Enables non-linear variables to be

displayed by the indicator in linear

engineering units. Use of the lineariser is

described in section 7 of this instruction

manual.

6.3

Resolution:

rE5n

This function defines the resolution of the least

significant display digit. Decreasing the display

resolution can improve the readability of a noisy

signal. Select

rE5n

from the menu and press

(

which will reveal the current display resolution.

To change the resolution press the

&

or

*

button to select

1

,

2

,

5

or

10

digits, followed by the

)

button to enter the selection and return to the

configuration menu.

6.4

Position of the decimal point:

dP

A dummy decimal point can be positioned between

any of the digits or it may be absent. To position

the decimal point select

dP

from the menu and

press

(

. The decimal point can be moved by

pressing the

&

or

*

push button. If a decimal

point is not required it should be positioned beyond

the most or least significant digit. When

positioned as required press the

)

button to enter

the selection and return to the configuration menu.

6.5

Calibration using an external

current source:

CAL

This function enables the zero and span of the

indicator to be adjusted using an external

calibrated current source. When used with an

accurate traceable current source this is the

preferred method of calibration.

Zero is the indicator display with 4mA input

Span is the indicator display with 20mA input

To calibrate the indicator select

CAL

from the

configuration menu and press

(

. The indicator

will display

2Ero

which is a request for a 4mA input

current. Adjust the external current calibrator to

4.000mA and again press

(

which will reveal the

current zero display. The flashing digit of the

indicator display can be changed by pressing the

&

or

*

buttons, when set as required pressing

(

will transfer control to the next digit. When all

the digits have been adjusted, press

)

to enter

the new zero and return to the

2Ero

prompt .

Pressing the

*

button will cause the indicator to

display

5PAn

which is a request for a 20mA input

current. Adjust the external current calibrator to

20.000mA and again press

(

which will reveal

the existing span display. The flashing digit of the

indicator display can be changed by pressing the

&

or

*

buttons, when set s required pressing

(

will transfer control to the next digit. When all the

digits have been adjusted press

)

to enter the

new span and return to the

5PAn

prompt. Finally

press

)

again to return to the configuration menu.

Notes:

a. The indicator input current must be adjusted to

the required value before the zero and span

functions are entered by pressing the

(

button.

b. Indicators may be calibrated at currents other

than 4 and 20mA, withiin the range 3.8 to

21.0mA providing the difference between the

two currents is greater than 4mA. If these

conditions are not complied with, the indicator

displays

FaiL

and aborts the calibration.

c. If the zero current is greater than the span

current the instrument will be reverse acting i.e.

an increasing input current will cause the

display to decrease.

Содержание BA304NG

Страница 1: ...Issue 4 1st November 2017 BA304NG BA324NG Ex nA Ex tc loop powered field mounting indicators Issue 4...

Страница 10: ...10...

Страница 15: ...15...

Страница 23: ...23...